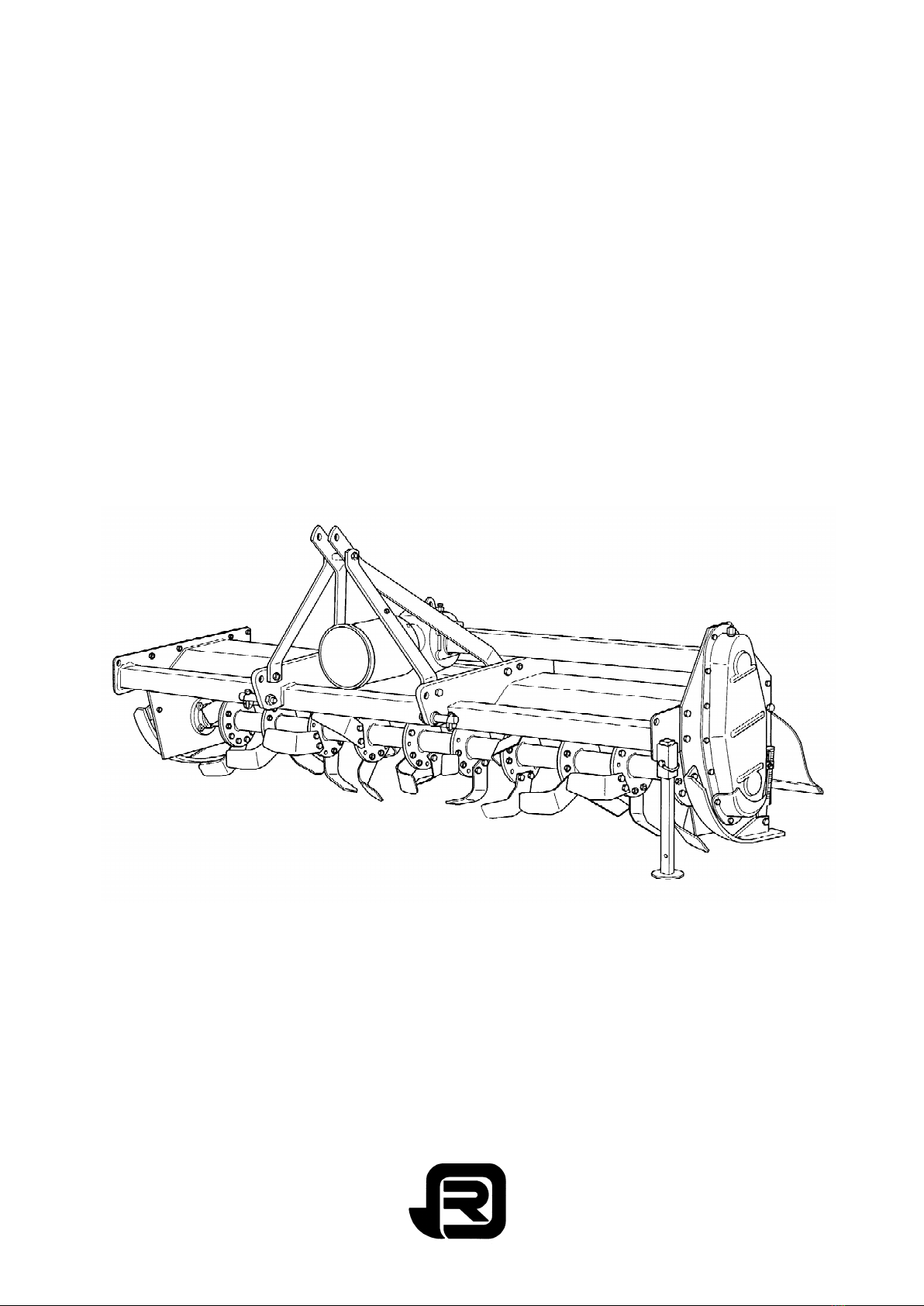

1 - GENERAL INFORMATION

Thank you and congratulations for having chosen our tiller.

Your new tiller is a technologically advanced machine constructed of

high quality sturdy components and will fulfil your working expectations.

Read this manual carefully. It will instruct you on how to operate and

service your machine safely and correctly. Failure to do so could result

in personal injury and or equipment damage.

2 - SAFETY PRECAUTIONS

Safety is the primary concern in the design and manufacture of our

products. Unfortunately our efforts to provide safe equipment can be

wiped out by a single careless act of an operator.

In addition to the design and configuration of equipment, hazard control

and accident prevention are dependent upon the awareness, concern,

prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of equipment. Allow only properly

trained personnel to operate the machine.

This symbol means:

- Attention!

- Become alert!

- Your safety is involved!

2.01 - Preparation

1. Before operating equipment read and understand the operator's

manual and the safety signs (see #3, fig. 1).

2. Thoroughly inspect the implement before initial operation to

assure that all packaging materials, i.e. wires, bands, and tape

have been removed.

3. Operate the machine only with a tractor equipped with an

approved Roll-Over-Protective-System (ROPS). Always wear your

seat belt. Serious injury or even death could result from falling off

the tractor.

4. Clear area to be worked of stones, branches or other debris that

might be thrown, causing injury or damage.

5. Operate only in daylight or good artificial light.

6. Ensure that all safety shielding and safety signs are properly

installed and in good condition (see fig. 1).

7. Be sure that no one is near the machine prior to engaging or while

the machine is working (see #7, fig. 1).

2.02 - Operational Safety

1. Be sure the tractor is in "Neutral" before starting engine.

2. Equipment operating power is supplied from tractor PTO. Refer to

your tractor manual for PTO engagement and disengagement

instructions. Always operate PTO at 540 rpm. Know how to stop

the tractor and machine quickly in case of an emergency.

3. Only use this model implement with tractors in the correct power

range (see table 1).

4. When engaging PTO, the engine rpm should always be low. Once

engaged and ready to start working, raise PTO speed to 540 rpm

and maintain throughout operation.

5. After striking an obstacle, disengage the PTO, shut the tractor

down and thoroughly inspect for damage before restarting.

6. Before engaging PTO, lift tiller clear of the ground by no more than

4-5 cm. (1,5"-2").

7. Before dismounting tractor: allow moving parts to stop, stop

engine, set brake and remove the key of unattended equipment.

8. Keep away from rotating blades and driveline (see #2 & 6, fig. 1).

9. Do not use with bystanders in area (see #7, fig. 1).

10. Allow no riders on tractor or machine (see #8, fig. 1).

11. Never place hands or feet under the implement with tractor engine

running or before you are sure all motion has stopped. Stay clear

of all moving parts (see #2, fig. 1).

12. Check the tractor PTO rpm to ensure it is set at 540 and turns

clockwise (see #5, fig. 1).

13. Reduce speed on slopes and sharp turns to minimise tipping or

loss of control. Be careful when changing directions on slopes. Do

not start or stop suddenly on slopes. Avoid operation on steep

slopes. Always use down slopes; never across the face.

14. When using a unit, a minimum 20% of tractor and equipment

weight must be on tractor front wheels. Without this weight, tractor

could tip over, causing personal injury or death. The weight may

be attained with a front end loader, front wheel weights, ballast in

tires or front tractor weights. When attaining a minimum 20% of

tractor and equipment weight on the front wheels, you must not

exceed the ROPS weight certification. Weigh the tractor and

equipment. Do not guess or estimate!

15. Inspect the entire machine periodically. Look for loose fasteners,

worn or broken parts. Be certain that all hardware is properly

tightened, specially blade bolts.

2.03 - Maintenance Safety

1. Good maintenance is your responsibility.

2. Make no repair or adjustments with the tractor engine running.

Before working on the machine, disengage the PTO, shut off the

engine, set the brakes, and remove the ignition key (see #4, fig.

1).

3. Be certain all moving parts on attachment have come to a

complete stop before attempting to perform maintenance.

4. Never work under equipment unless it is blocked securely.

5. Always use personal protection devices such as eye, hand and

hearing protectors, when performing any service or maintenance.

6. When completing a maintenance or service function, make sure

all safety shields and devices are installed before placing unit in

service (see #1, fig. 1).

7. When the machine is not hooked to the tractor, the driveline must

be supported by the storage hook to the top link.

8. Where replacement parts are necessary for periodic maintenance

and servicing, genuine replacement parts must be used to restore

your equipment to original specifications. The company will not

claim responsibility for use of unapproved parts and/or

accessories and other damages as a result of their use.

9. Unauthorised modifications to the machine may impair the

function and/or safety of the machine and reduce its life. If

equipment has been altered in any way from original design, the

manufacturer does not accept any liability for injury or warranty.

3 - OPERATION

You have purchased a rotary tiller designed especially for medium

sized tractors and for seed bed preparation.

The version T70 may be supplied with a tailgate, a rear cage roller (for

dry terrain) or with a spiked roller (for wet terrain).

3.01 - Setup and Lubrication

1. Lower the stand to support the tiller (see #1, fig. 2). Secure it in

place with the locking pin.

2. Ensure the breather plug (see #1, fig. 3) is screwed into the

gearbox. Check the gearbox oil level. It should be between

1

/

2

and

2

/

3

full. Use SAE 90.

3. Check all hardware for proper torque.

4. Grease driveline cross & bearing assemblies.

5. Grease the right rotor support bearing (see #1 & 2, fig. 4).

6. Hook up the rear shield adjustment chain (see #1, fig. 5) as

follows: slip one end of the chain through the U bolt (see #3, fig.

5) and then bolt it to the rear shield (see #2, fig. 5) in the

predisposed holes. Bolt the other end of the chain to the chain

hitch (see #4, fig. 5) located on the tiller frame. Ensure it is

tightened properly.

7. If the tiller is supplied with a rear roller, be sure to grease the roller

support bearings and the turnbuckle.

3.02 - Depth Control

The tilling depth is at its maximum when the skids are touching the side

plates. The more they are lowered the shallower the tiller works. Thus

the tilling depth is controlled by raising and lowering the side skids.

To do this:

1. loosen the nut (see #3, fig. 4) on the adjustment arm (see #4, fig.

4).

2. Place the skid (see #5, fig. 4) in the desired position.

3. Re-tighten the nut on the adjustment arm.

4. Repeat this operation on the other skid, ensuring both skids are

level.

When the machine is supplied with a rear roller rather than a tailgate,

the working depth is adjusted by the turnbuckle. Shortening the

turnbuckle will raise the roller and cause the tiller to work deeper,

ENGLISH

10

ROTOMEC