Contents

Introduction .......................................................................................................................................................................................... 2

Illumination .......................................................................................................................................................................................... 3

Aimer .................................................................................................................................................................................................... 3

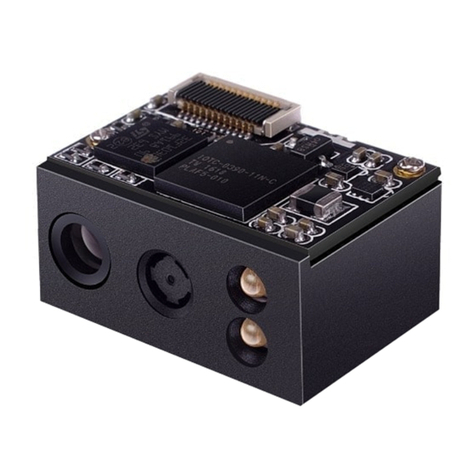

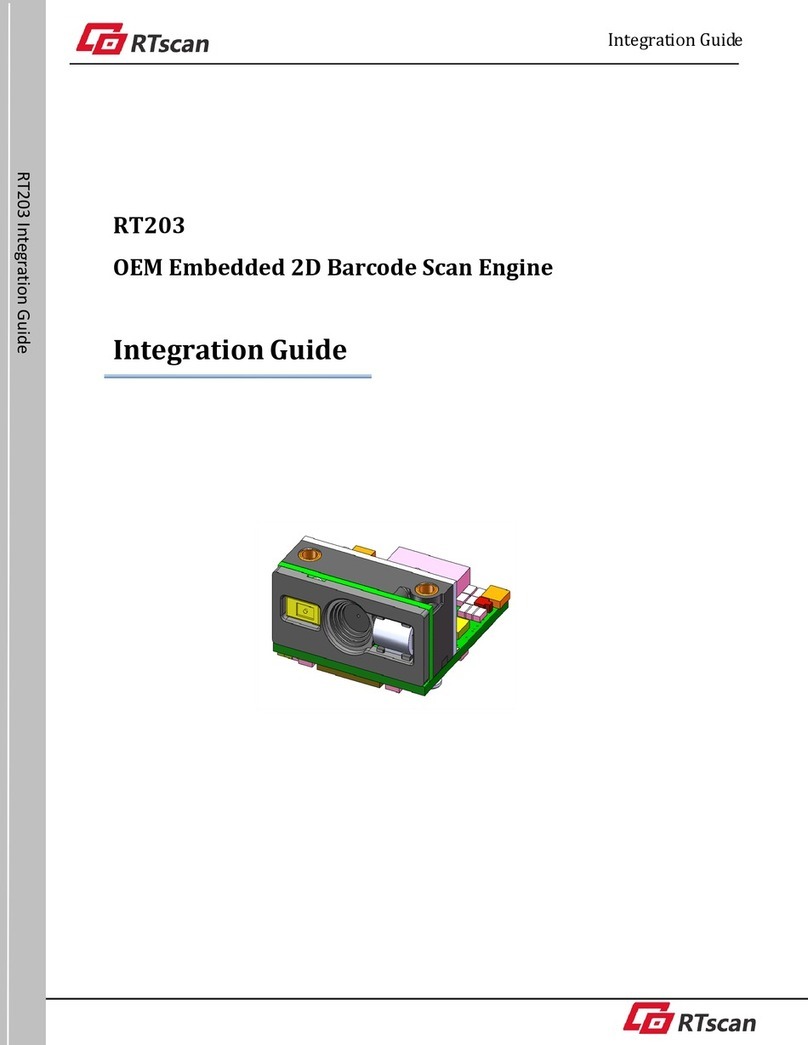

Introduction .......................................................................................................................................................................................... 4

General Requirements ........................................................................................................................................................................... 4

ESD ...............................................................................................................................................................................................4

Dust and Dirt ................................................................................................................................................................................ 4

Ambient Environment ...................................................................................................................................................................4

Thermal Considerations ................................................................................................................................................................5

External Optical Elements ............................................................................................................................................................. 5

Mounting ...............................................................................................................................................................................................6

Housing Design ..................................................................................................................................................................................... 7

Optics ....................................................................................................................................................................................................7

Window Placement ....................................................................................................................................................................... 7

Window Material and Color ...........................................................................................................................................................8

Coatings and Scratch Resistance ....................................................................................................................................................9

Window Size ............................................................................................................................................................................... 10

Roll, Skew and Pitch .................................................................................................................................................................... 11

Ambient Light ............................................................................................................................................................................. 11

Eye Safety ................................................................................................................................................................................... 11

Power Supply ...................................................................................................................................................................................... 12

Ripple Noise ........................................................................................................................................................................................ 12

Interface: .............................................................................................................................................................................................13

Connector Specifications ..................................................................................................................................................................... 17

External Circuit Design ........................................................................................................................................................................ 17

Beeper Circuit ............................................................................................................................................................................. 17