3VLBG-PLUS

• With shock loading or vibrations, especially at

through whole fixtures with a nut at the end of

the bolt, accidental release can occur.

Securing possibilities: Observe torque moment, use

liquid securing glue f.e. Loctite (can be adapted to the

usage, observe manufacturer hints) or assemble a

form closure bolt locking device f.e. a castle nut with

cotter pin, locknut etc.

• Finally check the proper assembly (see chapter 4

Inspection / repair).

3.3 User instructions

3.3.1 General information for the usage

• Always regularly observe the appearance of the whole

lifting point (e.g. xed lifting point/slings) before us-

ing it (secured bolt seat, strong corrosion, cracks on

load-bearing parts, deformations). Refer to chapter 4

Inspection / repair.

ATTENTION

Wrong assembled or damaged VLBG-PLUS as

well as improper use can lead to injuries of per-

sons and damage of objects when load drops.

Please inspect all VLBG-PLUS before each use.

• RUD components are designed according to DIN EN

818 and DIN EN 1677 for a dynamic load of 20,000

load cycles.

• Keep in mind that several load cycles can occur

with a lifting procedure

• Keep in mind that, due to the high dynamic stress

with high numbers of load cycles, that there is a

danger that the product will be damaged

• The BG/DGUV recommends: For higher dynamic

loading with a high number of load cycles (con-

tinuous operation), the working load stress must

be reduced according to the driving mechanism

group 1Bm (M3 in accordance with DIN EN

818-7). Use a lifting point with a higher working

load limit.

• When attaching and removing the lifting means (e.g.

lifting chains), crushing, shearing, trapping and impact

spots must be prevented.

• Prevent damage being caused to the lifting means by

loading at sharp edged.

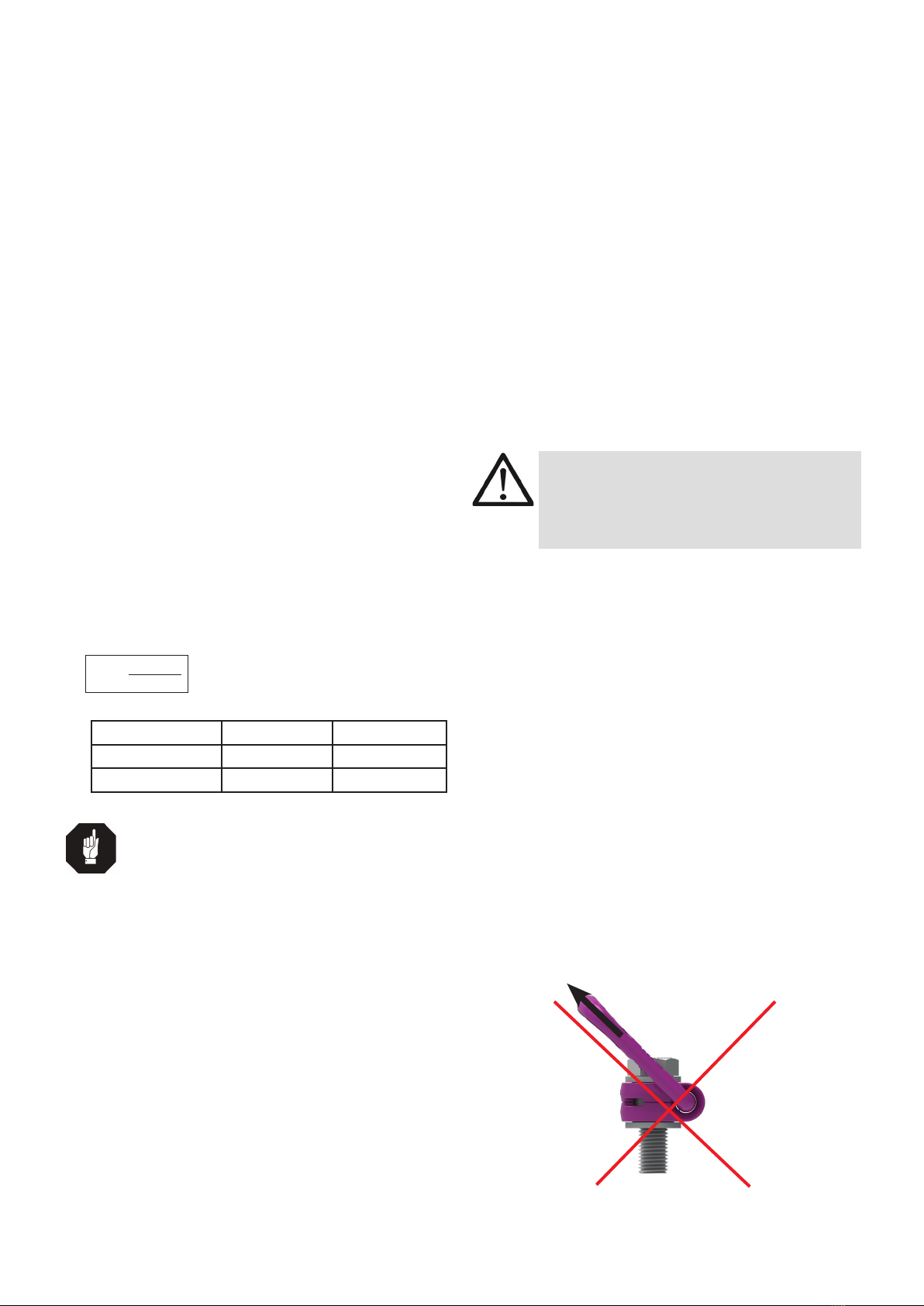

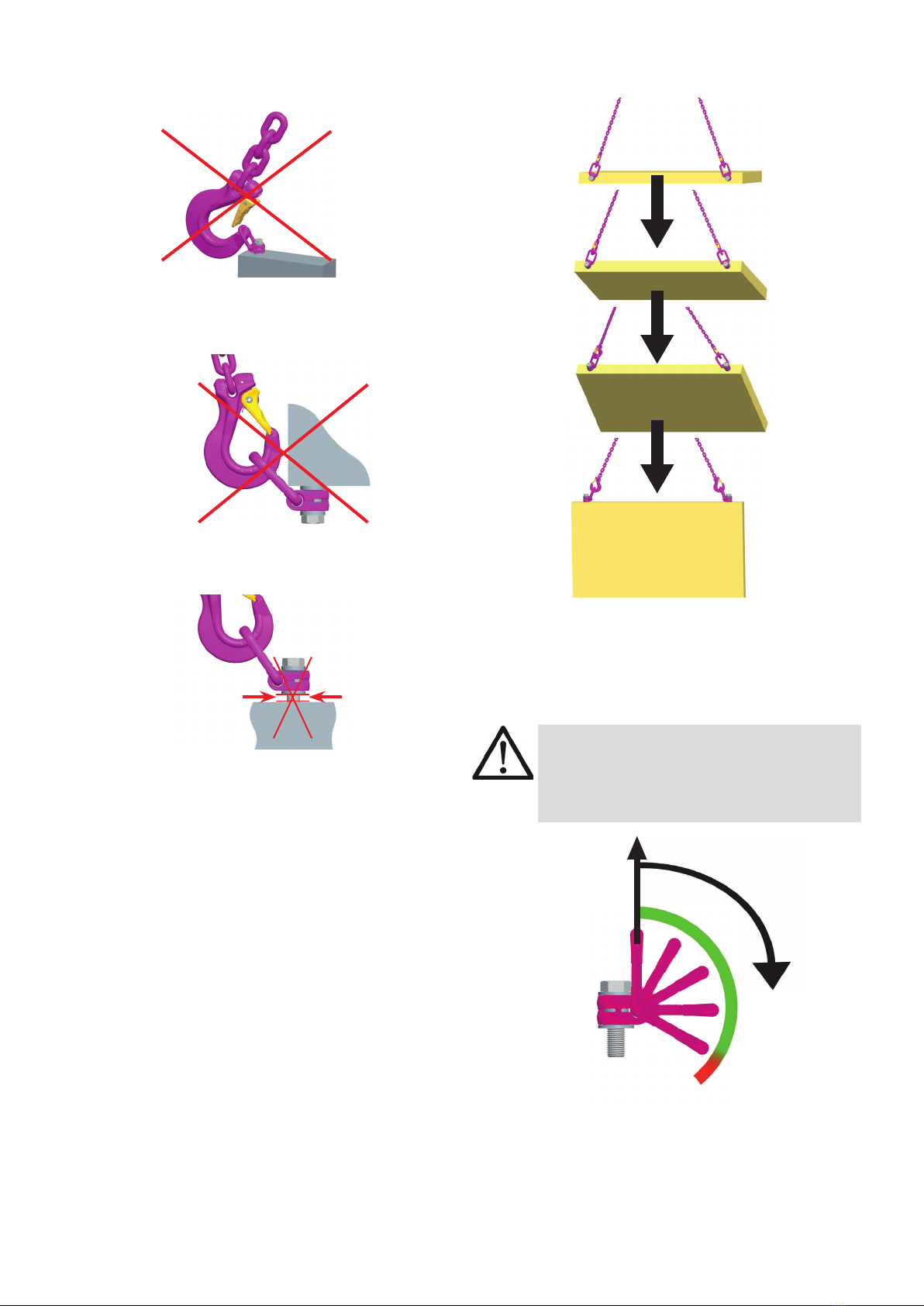

• Set the suspension ring of the VLBG-PLUS in the

direction of force before attaching the lifting means.

F

Pic. 1: Forbidden loading direction

3.2 Hints for the assembly

Basically essential:

• The material construction to which the lifting point

will be attached should be of adequate strength

to withstand forces during lifting without deforma-

tion. The German testing authority BG, recom-

mends the following minimum for bolt lengths:

1 x M in steel (minimum quality S235JR [1.0037])

1,25 x M in cast iron (for example GG 25)

2 x M in aluminium alloys

2.5 x M in aluminium-magnesium alloys

(M = diameter of RUD lifting point bolt, for ex. M 20)

• When lifting light metals, nonferrous heavy metals and

gray cast iron the thread has to be chosen in such a

way that the working load limit of the thread corre-

sponds to the requirements of the respective base

material.

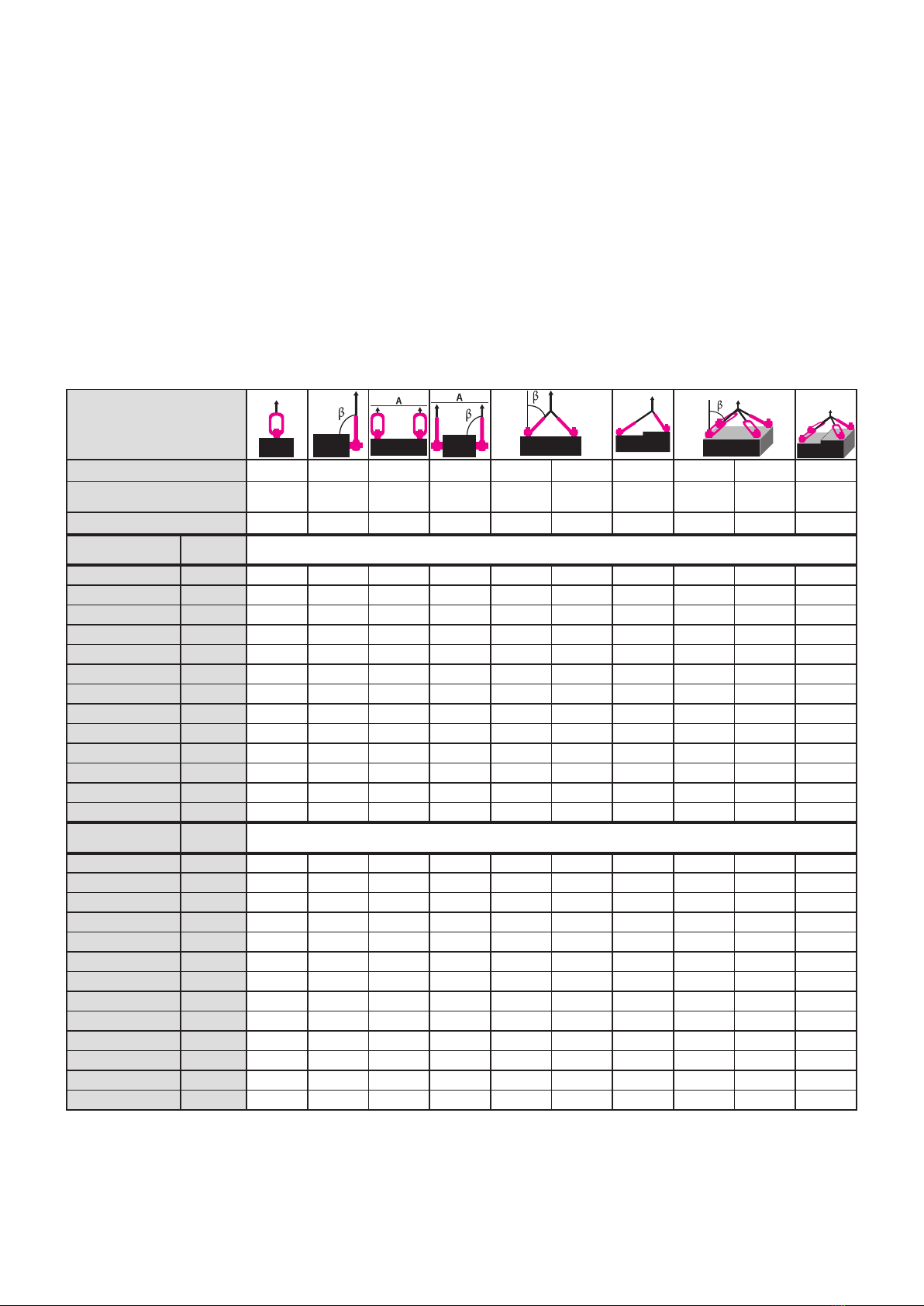

• The lifting points must be positioned on the load in

such a way that movement is avoided during lifting:

• For single leg lifts, the load ring should be

vertically above the centre of gravity of the load.

• For two leg lifts, the lifting points must be

equidistant to/or above the centre of gravity of the load.

• For three and four leg lifts, the lifting points

should be arranged symmetrically around the

centre of gravity in the same plane, if possible.

• Load symmetry:

The working load limit of individual RUD lifting points

are calculated using the following formula and are

based on symmetrical loading:

The calculation of load bearing legs is as follows:

Table 1: Load bearing strands (see table 2)

HINT

With unsymmetrical loads, the WLL of each Lift-

ing Point must be at least as high as the weight

of the load.

• A plane bolt-on surface (ØD, Tab. 3) with a perpendic-

ular thread hole must be guaranteed. The thread must

be carried out acc. to DIN 76 (countersink max. 1.05xd).

Tapped holes must be machined deep enough so that

the bearing surface of the lifting point will be supported.

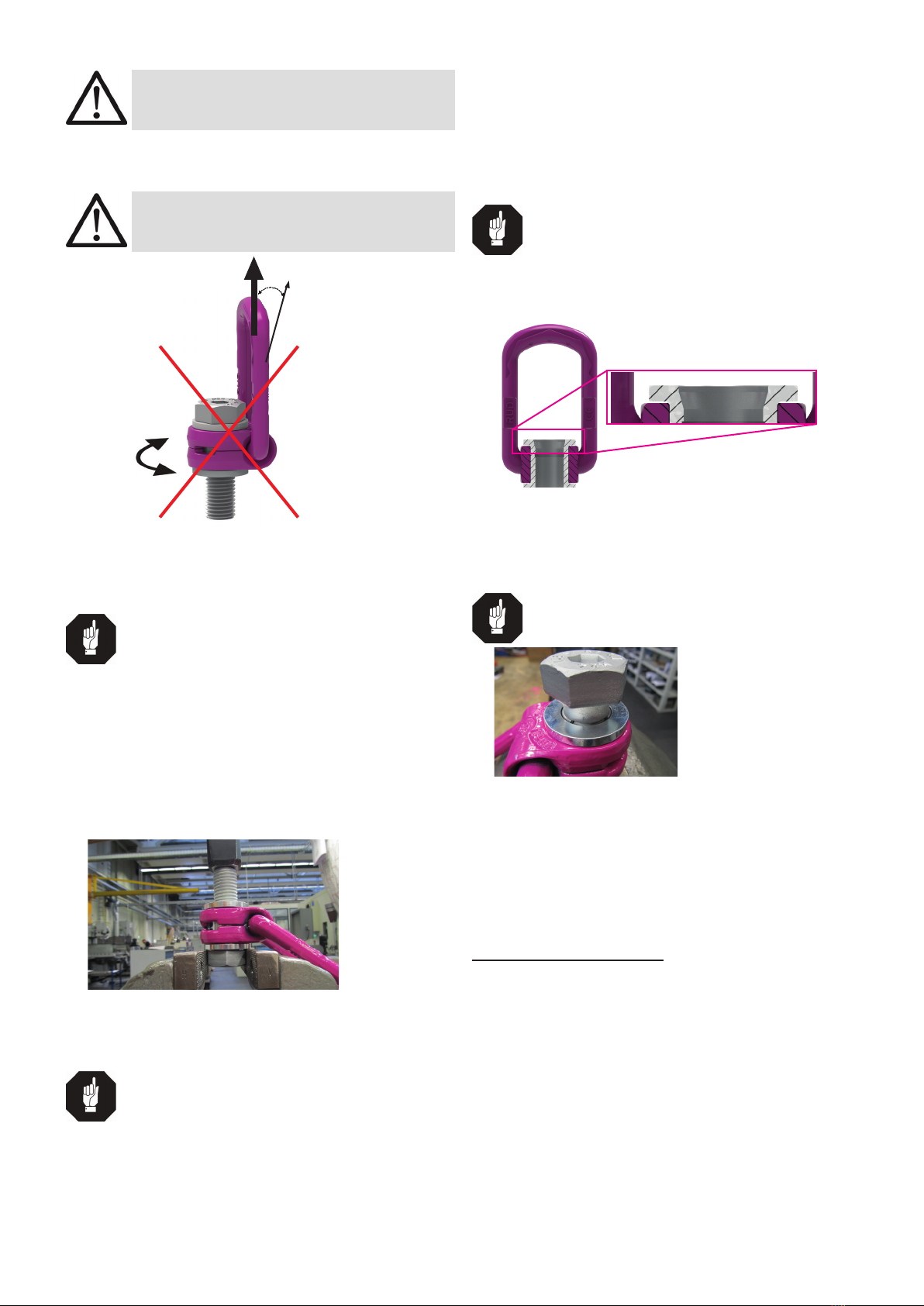

• The VLBG-PLUS must be rotatable 360° when in-

stalled. Please observe the following:

• For a single use hand tightening with a spanner

is sufcient. Bolt supporting area must sit proper

on bolt-on surface.

• For long term application the VLBG-PLUS must

be tightened with torque according to table 3

(+/- 10%).

• When turning loads using the VLBG-PLUS (see

chapter 3.3.2 permissible lifting- and turning pro-

cess) it is necessary to tighten the bolt with a torque

(+/- 10%) acc. to table 3.

symmetrical asymmetrical

two leg 2 1

three / four leg 3 1

WLL = working load limit

G = load weight (kg)

n = number of load bearing legs

ß = angle of inclination of the chain to the vertical

WLL=G

n x cos ß