2VWBG-V in pink

Before initial usage of the RUD VWBG-V

hoist rings please read carefully the safety

instructions. Make sure that you have un-

derstood all subjected matters.

Non-observance can lead to serious per-

sonal injuries and material damage and

eliminates warranty.

1 Safety instructions

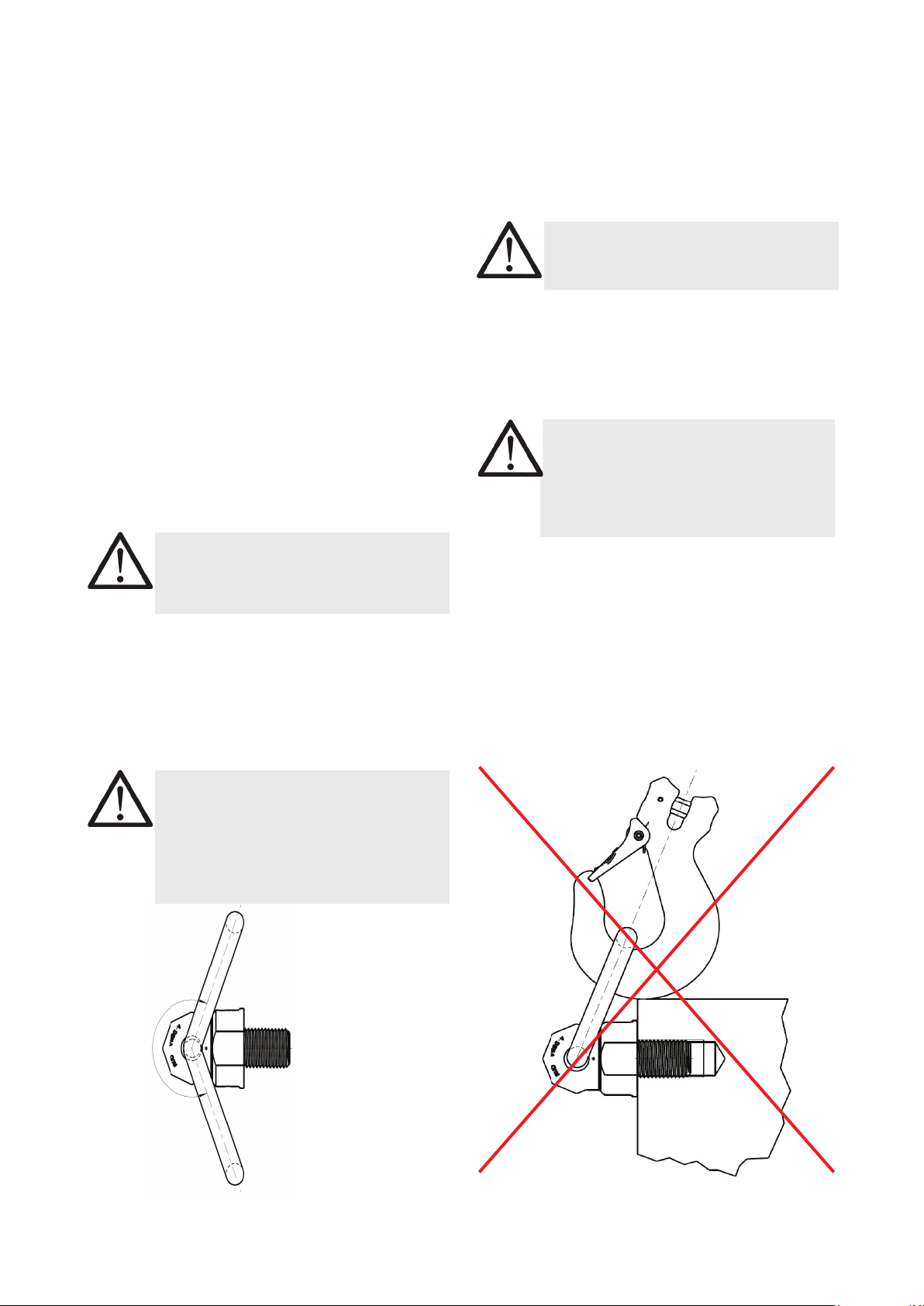

ATTENTION

Wrong assembled or damaged lifting points

as well as improper use can lead to injuries

of persons and damage of objects when

load drops.

Please inspect all lifting points before each

use.

• Not suitable for permanent turning operations un-

der load. Lifting point cannot be turned 90° to the

bolt-on direction under full load.

• The ball bearing resp. the bush bearing disc must

not be disassembled.

• The load ring must not be bend.

• RUD VWBG-V lifting points must only be used by

instructed and competent persons considering

BGR 500 / DGUV 100-500 and outside Germany

noticing the country specic statutory regulations.

2 Intended use of VWBG-V

RUD VWBG-V lifting points must only be used for the

assembly at the load or at lifting means.

They are intended to be hinged into lifting means

and can be turned under load, but not under full load,

especially not in the 90° direction. Not suitable for

permanent turning operations under load.

RUD VWBG-V lifting points can also be used as las-

hing points to attach lashing means.

RUD VWGB-V lifting points must only be used in the

hereby described operation purpose.

3 Assembly- and instruction manual

3.1 General information

• Capability of temperature usage:

Usage at higher temperatures is not recommended

due to the grease lling in the ball bearing. Should

this though be necessary, the working load limit

(WLL) of the VWBG-V must be reduced as follows:

-40°C up to 100°C no reduction

100°C up to 200°C minus 15 %

200°C up to 250°C minus 20 %

250°C up to 350°C minus 25 %

Temperatures exceeding 350°C are prohibited!

Please pay attention when using DIN EN 7042

(DIN 980) nuts the max. operation temperature

of 150°C (acc. to DIN EN ISO 2320).

• RUD VWBG-V lifting points must not be used with

aggressive chemicals such as acids, alkaline so-

lutions and their vapours.

• Please mark mounting position of lifting point with

a coloured contrast paint for better visibility.

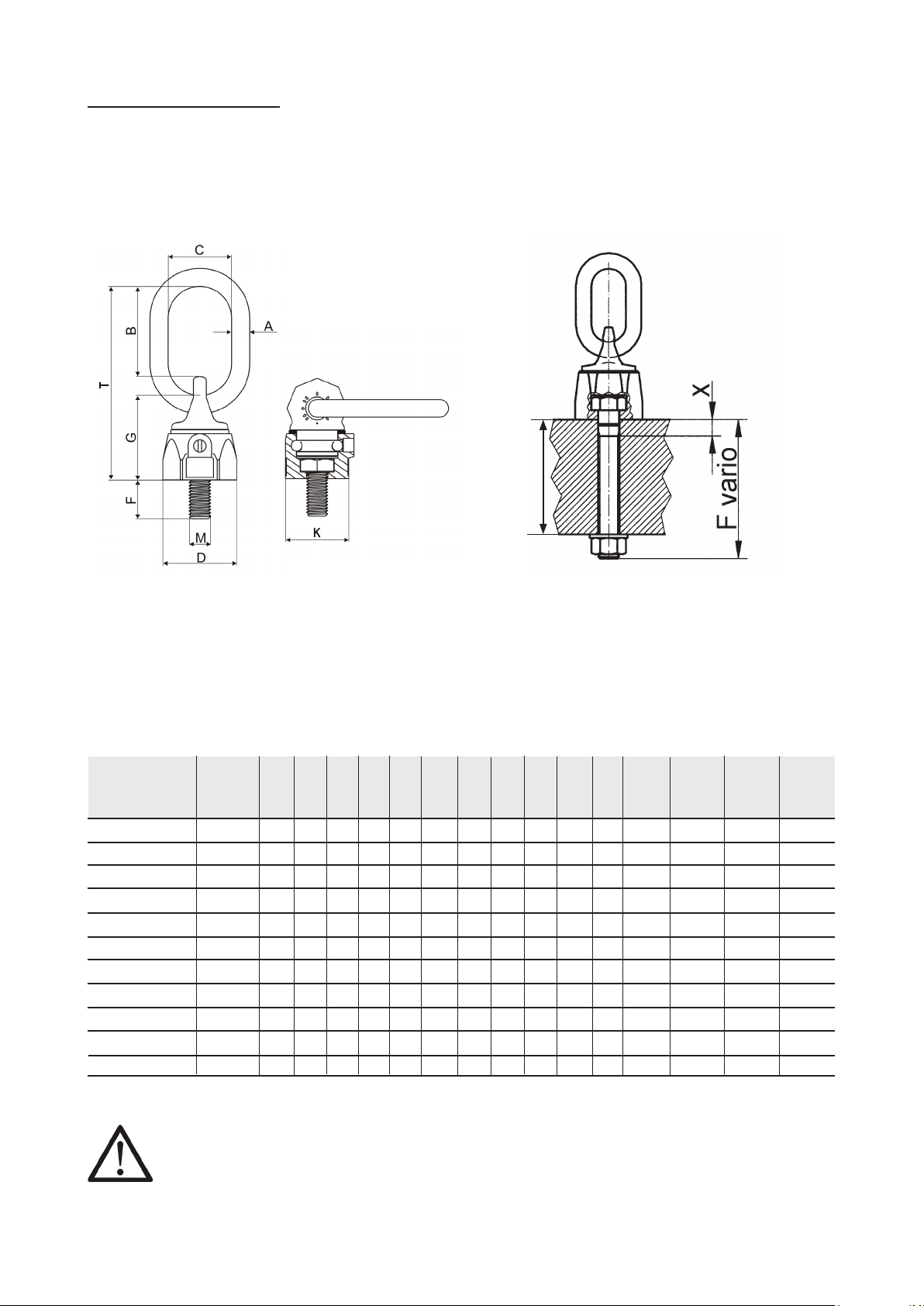

3.2 Hints for the assembly

Basically essential:

• The material construction to which the lifting point

will be attached should be of adequate strength to

withstand forces during lifting without deformation.

The German testing authority BG, recommends

the following minimum for the bolt lengths:

1 x M (thread diameter) in steel

(min. quality 235JR [1.0037])

1,25 x M (thread diameter) in cast iron

(e.g. GG 25)

2 x M (thread diameter) in aluminium

2,5 x M (thread diameter)

in light alloys of low strength

(M = thread size/diameter, e.g. M20)

• When lifting light metals, nonferrous metals and

gray cast iron the thread has to be chosen in such

a way that the WLL of the thread corresponds to

the requirements of the base material.

• The position of the lifting points must be carried

out in such a way that unintended movement like

turning or ipping will be avoided.

• For single leg lifts, the lifting point should

be vertically above the centre of gravity of

the load.

• For two leg lifts, the lifting points must be

equidistant to/or above the centre of gravity

of the load.

• For three and four leg lifts, the lifting points

should be arranged symmetrical around

the centre of gravity, in the same plane if

possible.

• Load symmetry:

Determine the necessary WLL of each lifting point

for a symmetrical or an unsymmetrical load by

using the following physical calculation formula:

Number of load bearing strands:

Symmetric Unsymmetric

two leg 2 1

three / four leg 3 1

Chart 1: Load bearing strands

WLL = necessary WLL of lifting point / single strand

G = weight of load

n = number of load bearing strands

ß = inclination angle of single strand

WLL=G

n x cos ß