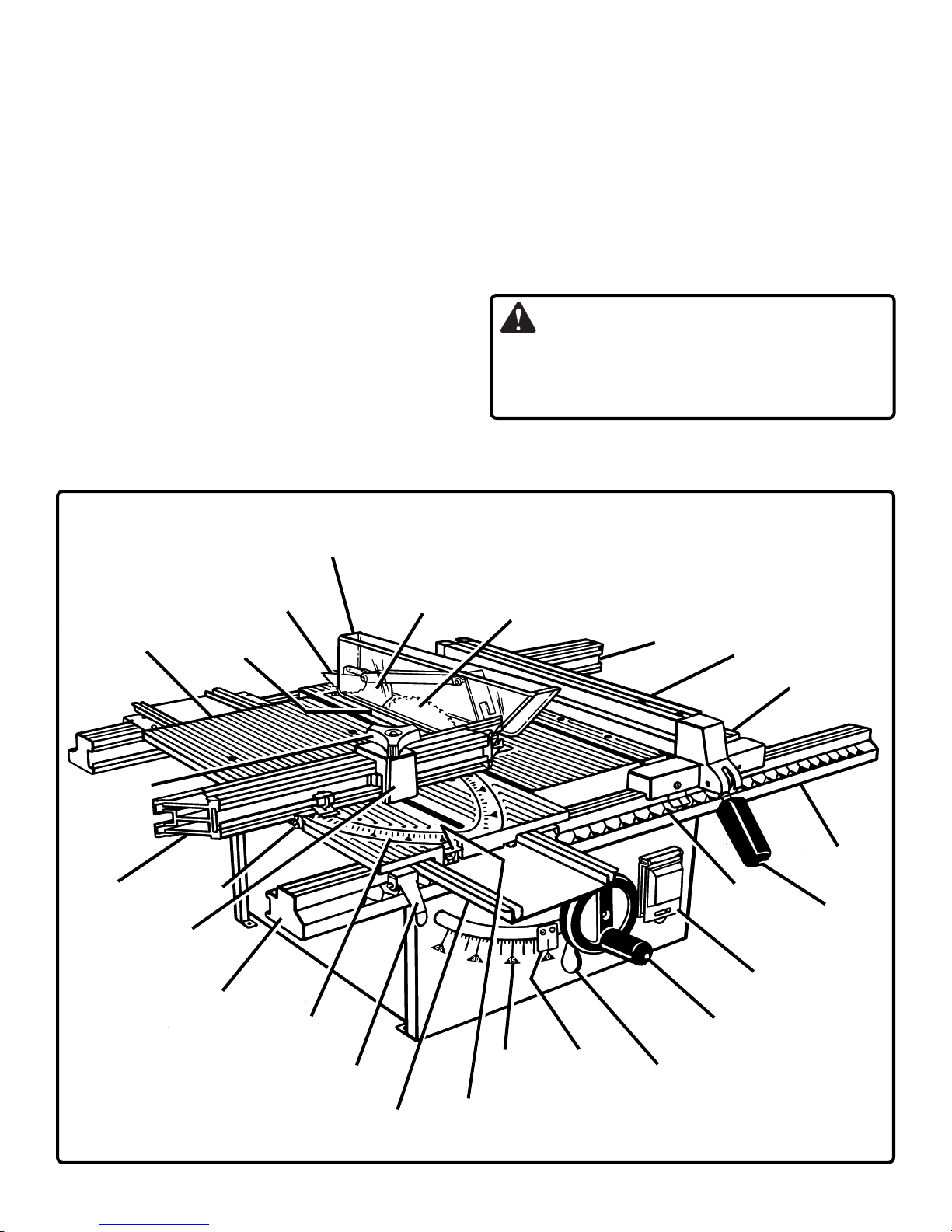

Page 4

RULES FOR SAFE OPERATION (Continued)

Safetyisacombinationofcommonsense,stayingalert,and

knowing how your table saw works. Read this manual to

understand this saw.

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL. Read the operator's

manual carefully. Learn the saw's applications and

limitations as well as the specific potential hazards

related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH GROUNDED

SURFACES. For example; pipes, radiators, ranges,

refrigerator enclosures.

3. GROUND YOUR SAW. Make sure that your saw is

properlypolarizedwithanapprovedgroundconnection.

4. ALWAYS KEEP THE BLADE GUARD AND RIVING

KNIFE (SPLITTER) IN PLACE and in working order.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benchesinviteaccidents.DONOTleavetoolsorpieces

of wood on the saw while it is in operation.

6. AVOID DANGEROUS ENVIRONMENT. Don't use

power tools in damp or wet locations or expose to rain.

Keep work area well lit.

7. KEEPCHILDRENAND VISITORS AWAY. Allvisitors

shouldwearsafetyglassesandbekeptasafedistance

from work area. Do not let visitors contact tool or

extension cord while operating.

8. MAKE WORKSHOP CHILD-PROOF with padlocks or

master switches, or by removing starter keys.

9. DON'TFORCETOOL. Itwilldothejobbetterandsafer

at the feed rate for which it was designed.

10. USERIGHTTOOL.Don'tforcetoolorattachmenttodo

a job it was not designed for. Don't use it for a purpose

not intended.

11. DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, or jewelry. They can get caught and

drawyouintomovingparts.Rubberglovesandnonskid

footwear are recommended when working outdoors.

Also wear protective hair covering to contain long hair.

12. ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses; they are NOT safety glasses.

13. PROTECT YOUR LUNGS. Wear a face or dust mask

if the cutting operation is dusty.

14. PROTECTYOURHEARING. Wearhearingprotection

during extended periods of operation.

15. DON'TABUSECORD. Neveryankcordtodisconnect

from receptacle. Keep cord from heat, oil, and sharp

edges.

16. DON'TOVERREACH. Keepproperfootingandbalance

at all times.

17. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow

instructions for lubricating and changing accessories.

18. DISCONNECT TOOLS. When not in use, before

servicing,or when changing attachments, blades, bits,

cutters, etc., all tools should be disconnected.

19. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

20. AVOID ACCIDENTAL STARTING. Be sure switch is

off when plugging in.

21. MAKESUREYOUREXTENSIONCORDISINGOOD

CONDITION.Whenusinganextensioncord,besureto

useoneheavyenoughtocarrythecurrentyourproduct

will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. A

wiregage size (A.W.G.) of at least 14 isrecommended

foranextensioncord25feetorlessinlength.Ifindoubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord. See Extension Cord

Caution on page 38.

22. USE OUTDOOR EXTENSION CORDS. When tool is

usedoutdoors,useonlyextensioncordswithapproved

ground connection that are intended for use outdoors

and so marked.

23. KEEP BLADES CLEAN AND SHARP. Sharp blades

minimize stalling and kickback.

24. KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from blades. Do not reach underneath

workoraroundoroverthebladewhilebladeisrotating.

Do not attempt to remove cut material when blade is

moving.

WARNING: Blades coast after turn off.

25. NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

26. INSPECTTOOLCORDSPERIODICALLY.Ifdamaged,

have repaired by a qualified service technician at an

authorizedservicefacility.Theconductorwithinsulation

having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductortoaliveterminal.Repairorreplaceadamaged

orworncordimmediately.Stayconstantlyawareofcord

location and keep it well away from the rotating blade.

27. INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

28. KEEP TOOL DRY, CLEAN, AND FREE FROM OIL

ANDGREASE. Alwaysuseacleanclothwhencleaning.

Never use brake fluids, gasoline, petroleum-based

products, or any solvents to clean tool.