1

WARNING

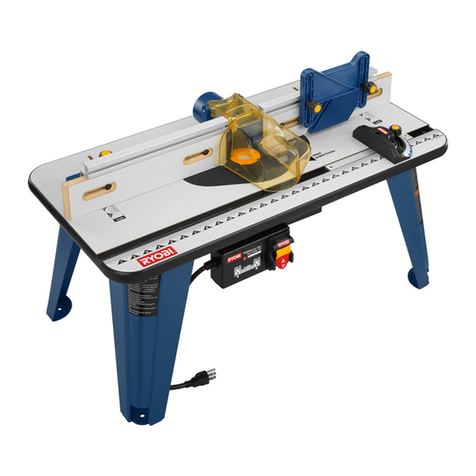

This router table can use Ryobi router

ERT1250VN, ERT241200 and ERT1500VK. Do

not use cutters with undersized shanks.

Undersized shanks will not tighten properly and

could be thrown from the tool, causing injury.

INTRODUCTION

Your router table has many features for making router

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

priority in the design of this router table making it easy to

maintain and operate.

CAUTION:

Carefully read through this entire Operator's

Manual and the entire router Operator’s Manual

before using your new router table. Pay close

attention to the Rules for Safe Operation and all

Safety Alert Symbols including Danger, Warning

and Caution. If you use your router table properly

and only for what it is intended, you will enjoy

years of safe, reliable service.

The operation of any tool can result in

foreign objects being thrown into your

eyes, which can result in severe eye

damage. Before beginning power tool

operation, always wear safety goggles

or safety glasses with side shields and a full face shield

when needed. We recommend Wide Vision Safety Mask

for use over eyeglasses or standard safety glasses with

side shields.

RULES FOR SAFE OPERATION

READ ALL INSTRUCTIONS

■Know your power tool. Safe operation of this power

tool requires that you read and understand this

operator’s manual, the Operator’s Manual for the

router and all labels affixed to the tool. Learn the

applications and limitations as well as the potential

hazards.

WARNING

Do not connect your router or router table to a

power source until you have assembled and

adjusted the router table as described in this

manual and have read and understood all

precautions and operating instructions in the

manual and printed on the tool.

WARNING

When using electric tools, basic safety precautions

should always be followed to reduce the risk of fire,

electric shock and personal injury. Use common

sense. Some of these basic safety precautions

include the following:

■Alwayskeep all guardsin place and in good

working order.

■Remove adjusting keysand wrenches.Get in the

habit of checking to see that hex keys and adjusting

wrenches are removed from the tool before turning it

on.

■Keep the work area clean. Cluttered work areas and

work benches invite accidents.

■Do not use in dangerousenvironments.Do not

use power tools near petrol or other flammable

liquids, in damp or wet locations or expose them to

rain. Keep the work area well lit.

■Keep children away from power tools.All visitors

should be kept at a safe distance from the work area.

■Make the workshop child-proof with padlocks and

master switches or by removing starter keys.

■Do not force the tool. It will do the job better and

safer at the rate for which it was designed.

■Use the right tool. Do not force the tool or

attachment to do a job for which it was not designed.

■Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry that

could get caught in moving parts. Non-slip footwear is

recommended. Wear protective covering over long

hair.

■Alwayswear safety glasseswith side shields.

Everyday eyeglasses have only impact resistant

lenses; they are not safety glasses.

■Protect your lungs.Wear a face or dust mask if the

cutting operation is dusty.

■Protect your hearing. Wear ear muffs or plugs

during periods of extended use.

■Secure the work. Use clamps or a vise to hold the

work when practical. It’s safer than using your hand

and frees both hands to operate the tool.

■Do not overreach. Keep proper footing and balance

at all times.

■Maintain the tool with care. Keep blades sharp and

clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

■Disconnect power toolsbefore servicing or before

changing accessories such as blades, bits and

cutters.

ART3-manual(RTA).qxd 9/10/04 4:23 PM Page 1