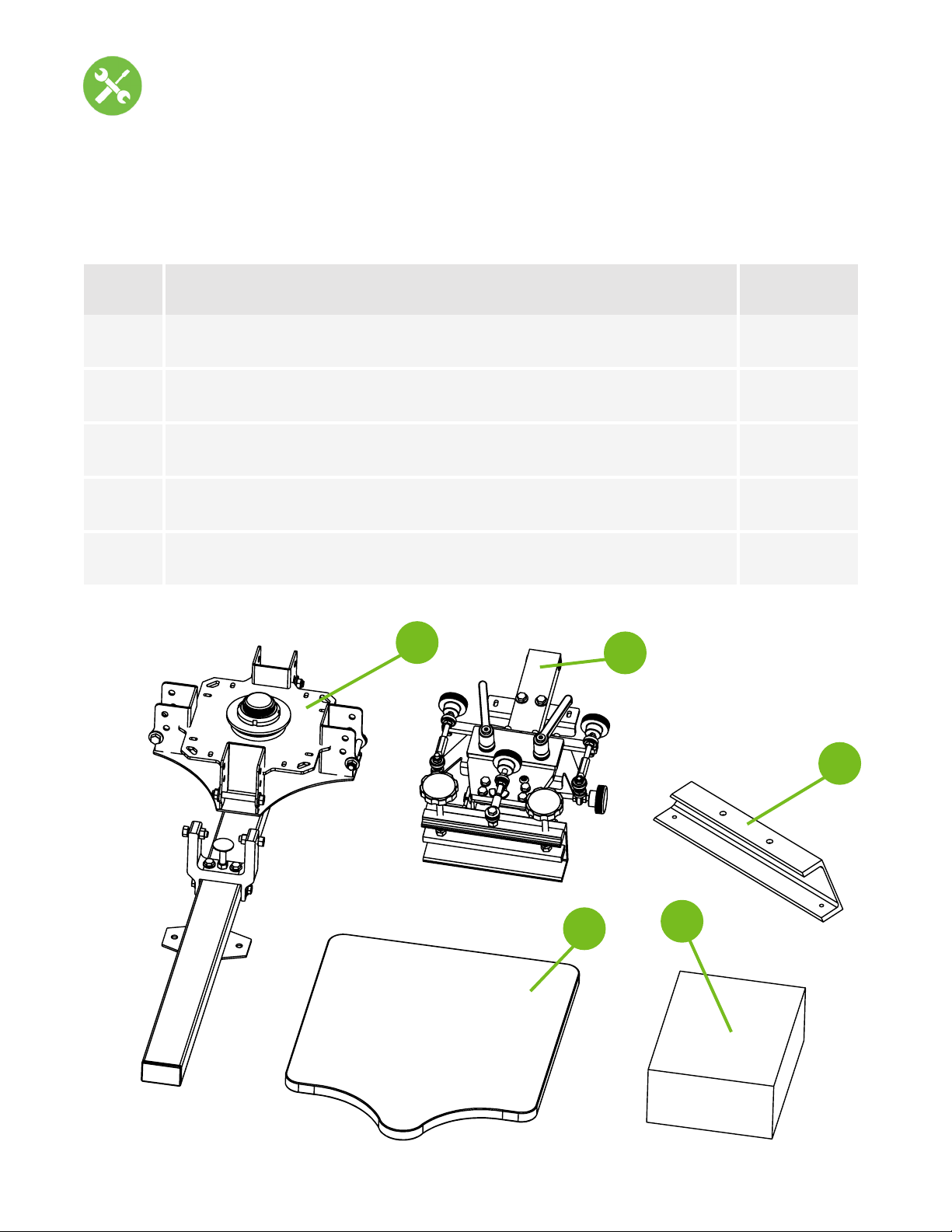

8

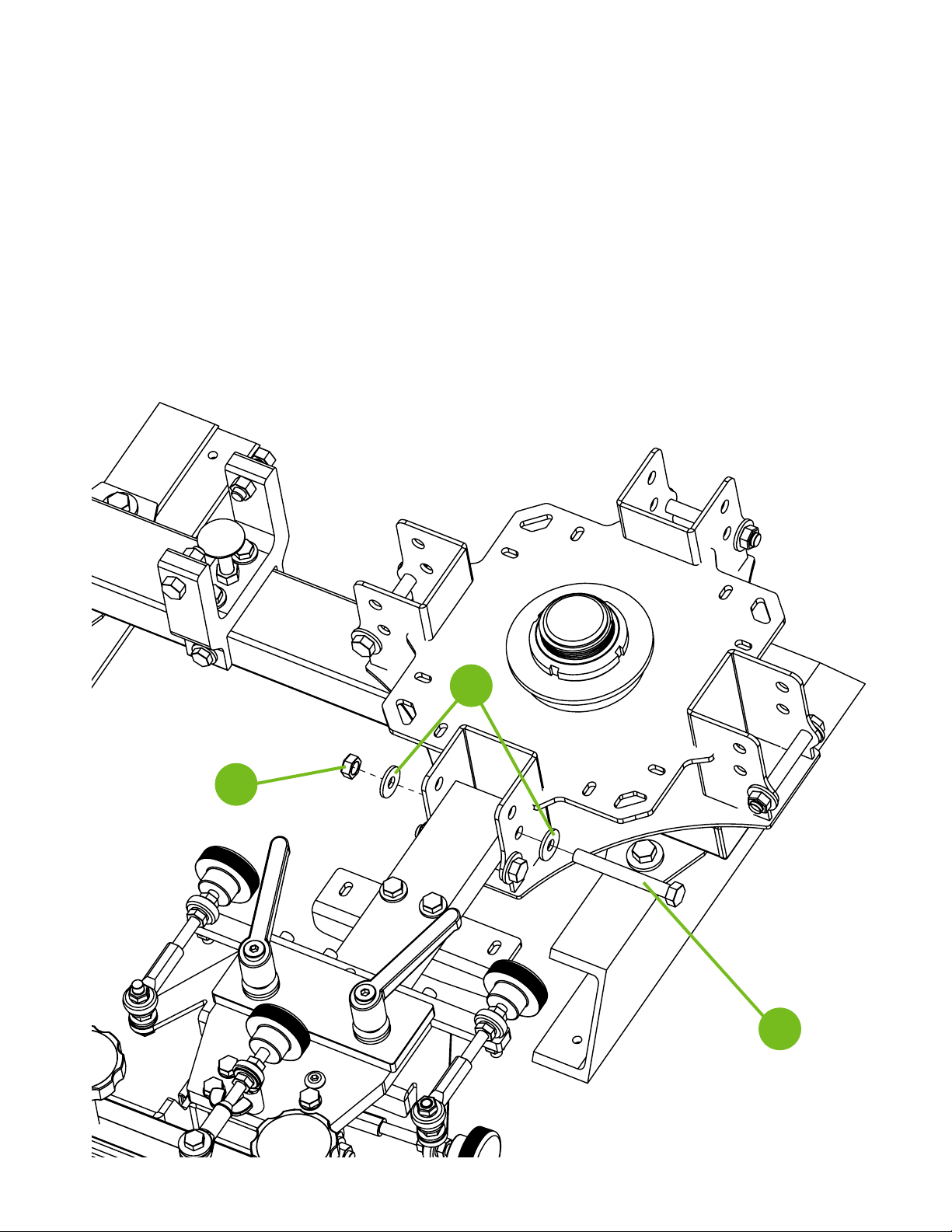

Step 4

Install the upper stop bolts and rubber sleeves. Two 9/16” wrenches

are required for this step. DO NOT OVERTIGHTEN THE BOLTS. This will

cause resistance in the print head hinge point. Repeat this step for the

remaining print head assemblies.

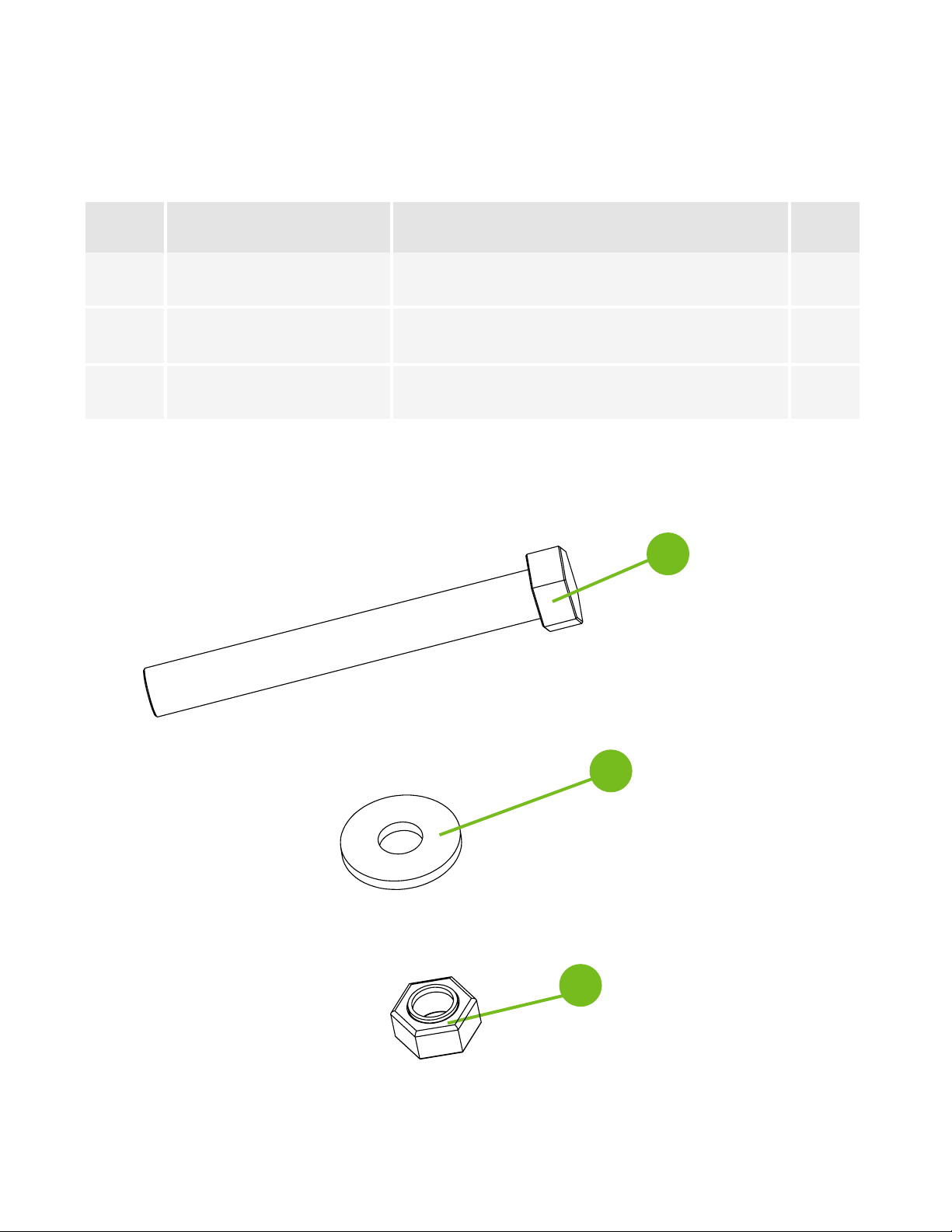

Note: Refer to Page 3 for hardware detail.

1

2

3

1

4

5