Contents

Section 1 ........................................................................................5

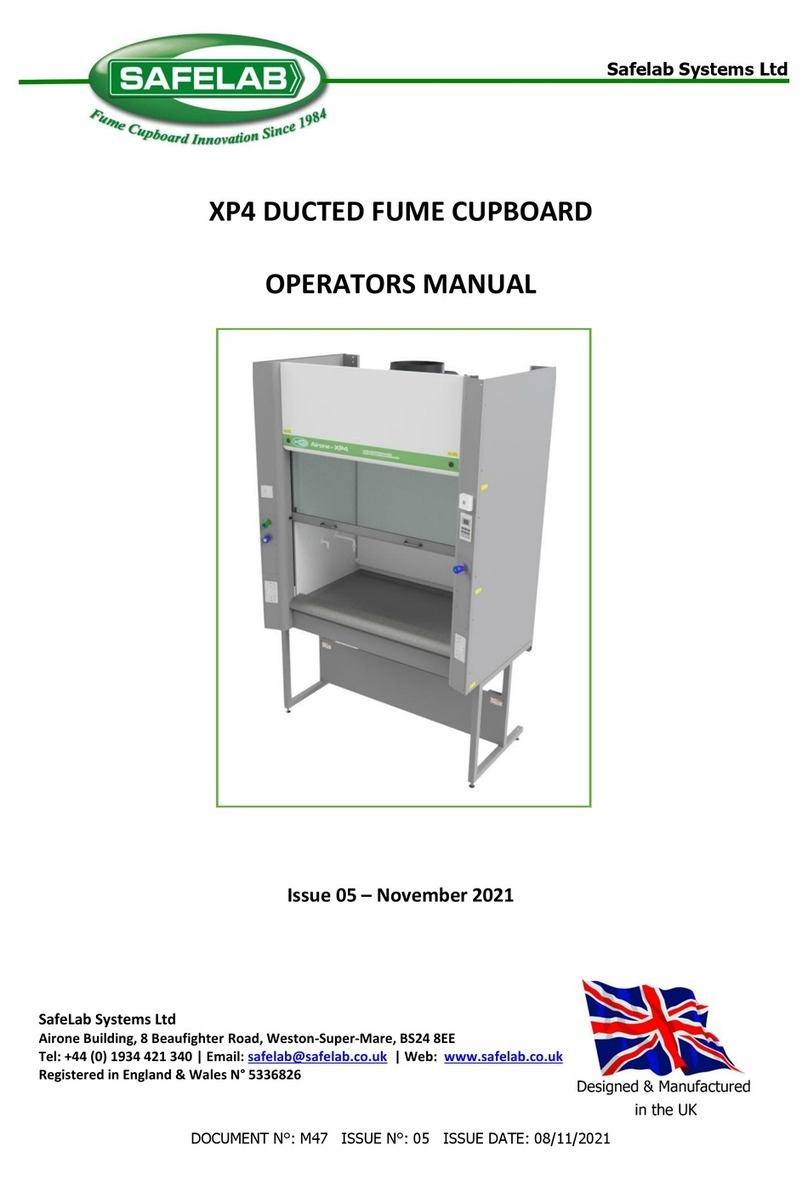

Description of the cabinet..................................................................................... 5

Working principal .................................................................................................. 5

Features.................................................................................................................. 5

Specifications ........................................................................................................ 6

Normal environmental conditions........................................................................ 6

SECTION 2 ......................................................................................7

Installation.............................................................................................................. 7

Important handling procedures............................................................................ 7

Location.................................................................................................................. 7

Ducting connection (optional).............................................................................. 7

Electrical connection and services...................................................................... 7

Auxiliary switched connection............................................................................. 7

Testing and certification....................................................................................... 7

SECTION 3 ......................................................................................8

Operating instructions.......................................................................................... 8

Basic operations.................................................................................................... 8

Cabinet overview................................................................................................... 8

Startup.................................................................................................................... 9

Controls................................................................................................................ 10

Home screen........................................................................................................ 10

Sliding sash operation........................................................................................ 11

Standby ................................................................................................................ 12

Switching the cabinet off.................................................................................... 12

Lighting ................................................................................................................ 13

Auxiliary power sockets...................................................................................... 13

Cleaning and disinfection................................................................................... 14

Surface cleaning and disinfection ..................................................................... 14

Glass front cleaning and disinfection................................................................ 14

UV Disinfection.................................................................................................... 14

Decontamination with Formaldehyde –Unit without the optional carbon

exhaust filter kit (CEF)......................................................................................... 15

Preparation prior to decontamination................................................................ 15

Decontamination with Formaldehyde –When using the optional carbon

exhaust filter kit (CEF)......................................................................................... 17

Preparation prior to decontamination................................................................ 17

Decontamination with VHP (Vaporised Hydrogen Peroxide)........................... 19

Preparation prior to decontamination................................................................ 19

SECTION 4 ....................................................................................20

Supervisor settings............................................................................................. 20

Airflow Display..................................................................................................... 21

Auto Start ............................................................................................................. 21

Auto Standby ....................................................................................................... 22

Cabinet access .................................................................................................... 23

Power Sockets..................................................................................................... 23

Keypad Sounds ................................................................................................... 23

Audible Alarm ...................................................................................................... 24