page 2

111v Tsarigradsko Shose blvd, 1784 Soa, Bulgaria | info@safetyeng.eu | www.safetyeng.eu

Table of contents

Table of contents .................................................................................................................................................. 2

1. Introduction and overview ........................................................................................................................... 3

2. Product identication ..................................................................................................................................... 4

3. Certication ........................................................................................................................................................ 4

4. Manufacturer information ............................................................................................................................. 5

5. Conformity assessment ................................................................................................................................... 5

6. Register your device ....................................................................................................................................... 5

7. Compatibility with autobelay devices and harness ......................................................................... 5

8. Device specication ...................................................................................................................................... 6

9. Installation ............................................................................................................................................... 7

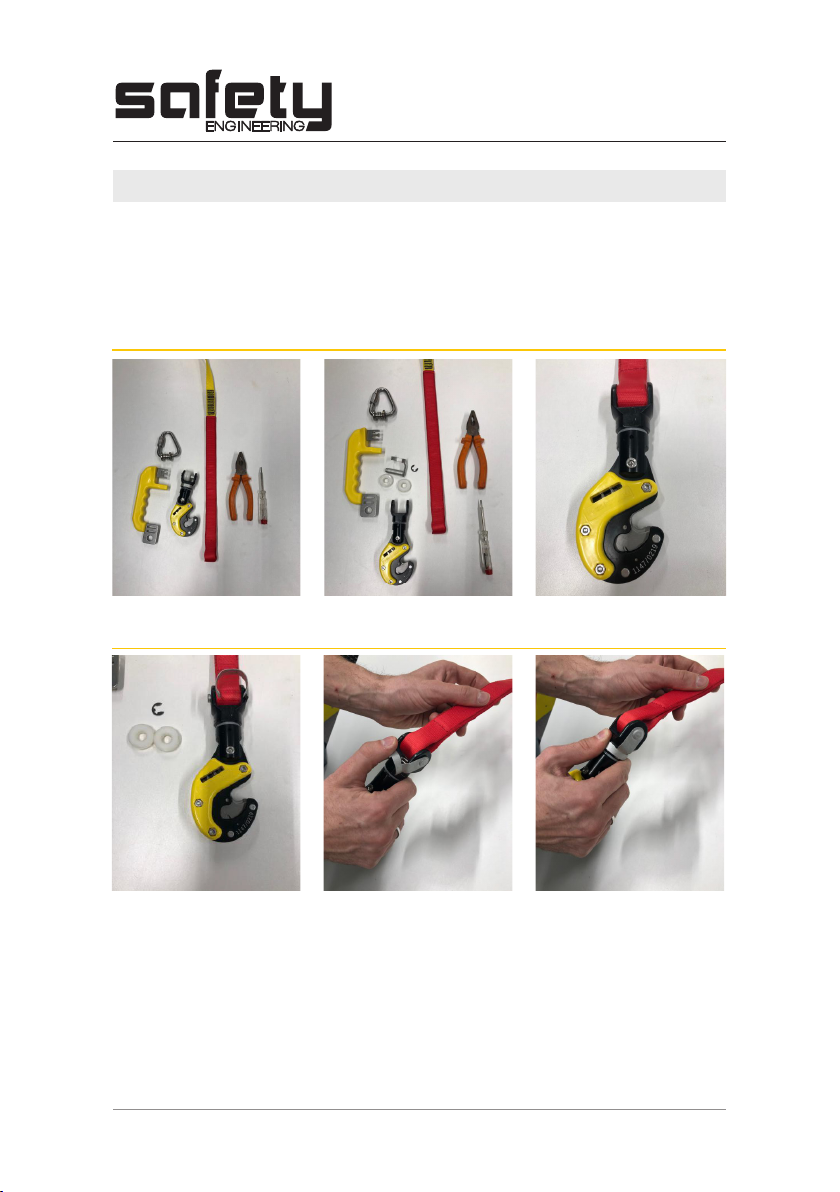

9.1. Prepare the Self Belay device ......................................................................................................... 7

9.2. Installation on steel cable ................................................................................................................... 8

9.3. Installation on textile webbing ........................................................................................................ 9

9.4. Installation of quicklinks to user harness .................................................................................. 10

9.5. Installation of Self Belay key ........................................................................................................... 11

10. Usage of the Self Belay ........................................................................................................................... 11

11. Inspection and maintenance ................................................................................................................. 13

11.1.Dailyinspection.......................................................................................................................................13

11.2. General care ............................................................................................................................................ 16

11.3. Daily checklist ......................................................................................................................................... 18

11.4. Annual maintenance and recertication ...................................................................................... 19

12. Lifespan ....................................................................................................................................................... 22

13. Warranty information ......................................................................................................................... 22