8

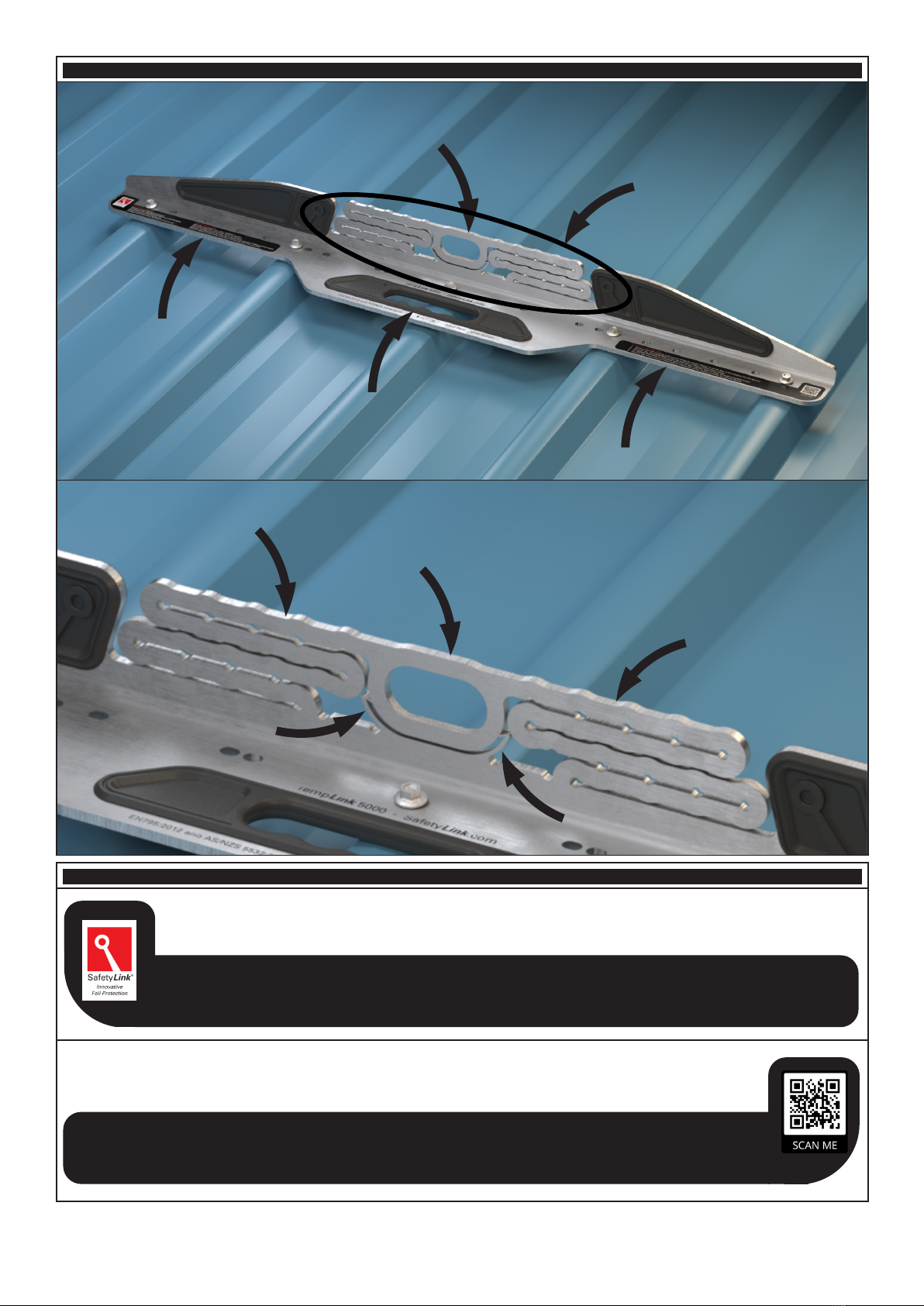

SafetyLink Pty Ltd | ABN 83 081 777 371 | www.safetylink.com

Head Office: 54 Bonville Ave, Thornton, 2322, NSW, Australia

1300 789 545 | +61 2 4964 1068

WARRANTIES

EXTRACT: SAFETYLINK PTY LTD STANDARD TERMS AND CONDITIONS

1.1 To the extent permitted by law all implied conditions, warranties and undertakings are expressly excluded.

1.2 Except as provided in this clause the Company shall not be liable for any loss or damage, whether direct or indirect (including consequential

losses or damage) arising out of any breach of contract by the Company or any negligence of the Company, its employees or agents.

1.3 Should the Company be liable for a breach of a guarantee, condition or warranty implied by the Australian Consumer Law (not being a

guarantee, condition or warranty implied by sections 51, 52 and 53 of that Law) then its liability for a breach of any such condition or warranty express

or implied shall be limited, at its option, to any one or more of the following.

A in case of Goods

I the replacement of the Goods or the supply of equivalent Goods.

II the repair of the goods,

III the payment of the cost of replacing the Goods or acquiring equivalent Goods.

IV the payment of the cost of having the Goods repaired. Provided that any such Goods are returned to the Company by the Purchaser at

the Purchaser’s expense.

B in the case of services

I the supply of the services again,

II the payment of the cost of having the services supplies again.

1.4 The Company is not liable for the costs of recovery of the Goods from the field, loss of use of the Goods, loss of time, inconvenience,

incidental or consequential loss or damage, nor for any other loss or damage other than as stated above, whether ordinary or exemplary,

caused either directly or indirectly by use of the Goods.

1.5 The Company warrants that at the time of shipment, Products manufactured by it will be free from defects in material and

workmanship. In the absence of a modified written warranty, the Company agrees to making good any such defects by repairing the same or at the

Company’s option by replacement, for a period of (1) one year from the date of shipment. This limited warranty applies provided that:

a defects have arising solely from faulty materials or workmanship;

b the Products have not received maltreatment, inattention or interference;

c the Products have been installed in accordance with the Company’s Installation Handbooks using only products supplied by the Company;

d accessories used with the Products are manufactured by or approved by the Company

e the Products are maintained in accordance with Australian Standard 1891.4 (section 9).

f you notify any claim under this warranty to SafetyLink in writing to the address below no later than 14 days after the event or occurrence

concerning the produce giving rise to the claim and you pay all costs related to your claim.

This warranty does not apply to any defects or other malfunctions caused to the Goods by accident, neglect, vandalism, misuse, alteration, modification

or unusual physical, environment or electrical stress.

Please note that the benefits to the purchaser (as a consumer) given by this warranty are in addition to your other rights and remedies under the Australian

Consumer Law. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or

refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

1.6 If any goods are not manufactured by the Company, the guarantee of the manufacturer thereof shall be accepted by the Purchaser as the only

express warranty given in respect of the goods.

1.7 Except as provided in this clause 11, all express and implied warranties, guarantees and conditions under statute or general law as

the merchantability, description, quality, suitability or fitness of the Products for any purpose or as to design, assembly, installation, materials or

workmanship or otherwise are hereby expressly excluded (to the extent to which they may be excluded by law).

PLEASE SEE SAFETYLINK PTY LTD FULL STANDARD TERMS OF CONDITIONS OF SALE FOR FURTHER REFERENCE.