Contents

EB 5840 EN 3

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1‑4

1.2 Notes on possible personal injury ................................................................1‑4

1.3 Notes on possible property damage.............................................................1‑6

2 Markings on the device ..............................................................................2-1

2.1 Actuator nameplate.....................................................................................2‑1

3 Design and principle of operation ...............................................................3-1

3.1 Direction of action.......................................................................................3‑1

3.2 Signal pressure routing................................................................................3‑1

3.3 Fail‑safe action ...........................................................................................3‑3

3.3.1 Version with direction of action "actuator stem extends".................................3‑4

3.3.2 Version with direction of action "actuator stem retracts" .................................3‑4

3.4 Accessories ................................................................................................3‑4

3.5 Technical data ............................................................................................3‑4

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4‑1

4.2 Removing the packaging from the actuator ...................................................4‑1

4.3 Transporting and lifting the actuator .............................................................4‑1

4.3.1 Transporting the actuator.............................................................................4‑1

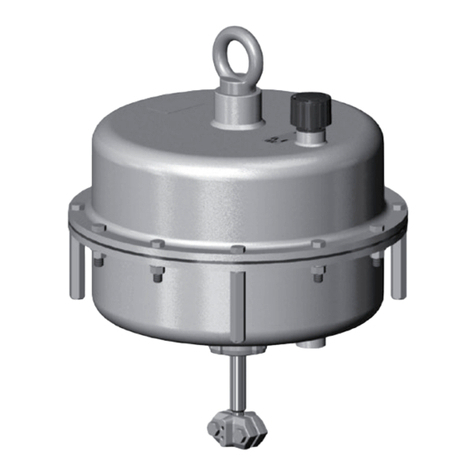

4.3.2 Lifting the actuator ......................................................................................4‑2

4.4 Storing the actuator.....................................................................................4‑2

5 Mounting ...................................................................................................5-1

5.1 Preparation for mounting.............................................................................5‑1

5.2 Mounting the actuator .................................................................................5‑1

5.2.1 Mounting the actuator onto the valve............................................................5‑2

5.2.2 Connecting the air supply............................................................................5‑3

6 Operation..................................................................................................6-1

6.1 Supply pressure in closed‑loop operation......................................................6‑2

7 Malfunctions ..............................................................................................7-1

7.1 Troubleshooting ..........................................................................................7‑1

7.2 Emergency action .......................................................................................7‑2