Contents

EB 6495-2 EN

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1-3

1.2 Notes on possible property damage.............................................................1-4

2 Markings on the device ..............................................................................2-1

2.1 Housing inscription .....................................................................................2-1

2.2 Article code................................................................................................2-2

2.3 Firmware versions.......................................................................................2-2

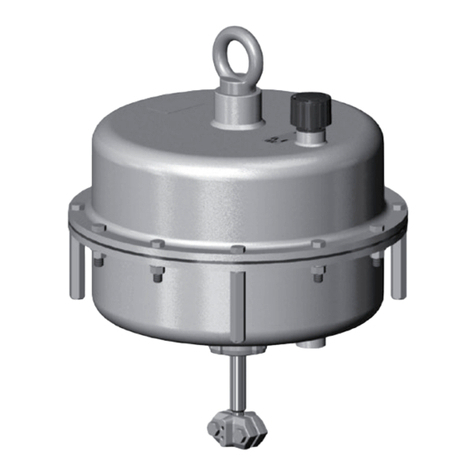

3 Design and principle of operation ...............................................................3-1

3.1 Block diagrams...........................................................................................3-4

3.2 Technical data ..........................................................................................3-12

3.3 Dimensions...............................................................................................3-16

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removing the packaging from the industrial controller....................................4-1

4.3 Transporting the industrial controller.............................................................4-1

4.4 Lifting the industrial controller ......................................................................4-1

4.5 Storing the industrial controller.....................................................................4-2

5 Installation.................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-1

5.3 Mounting the industrial controller .................................................................5-1

5.4 Installing the interface board........................................................................5-2

5.5 Electrical connection....................................................................................5-3

6 Operation..................................................................................................6-1

6.1 Device overview..........................................................................................6-1

6.2 Operating controls......................................................................................6-3

6.3 Operating structure.....................................................................................6-4

7 Start-upandconguration..........................................................................7-1

7.1 Conguration .............................................................................................7-1

7.1.1 Enteringthecongurationmenu...................................................................7-5

7.1.2 Conguringthecontroller ............................................................................7-5

7.1.1.1 Settingcongurationitems...........................................................................7-6

7.1.2.1 Congurationexample................................................................................7-7

7.1.3 Adapting the display direction .....................................................................7-8

7.1.3.1 Changing the controller display....................................................................7-9

7.1.3.2 Setting up additional display......................................................................7-11