EB 9527-2 EN 5

TROVIS-VIEW4 software

1 TROVIS-VIEW4 software

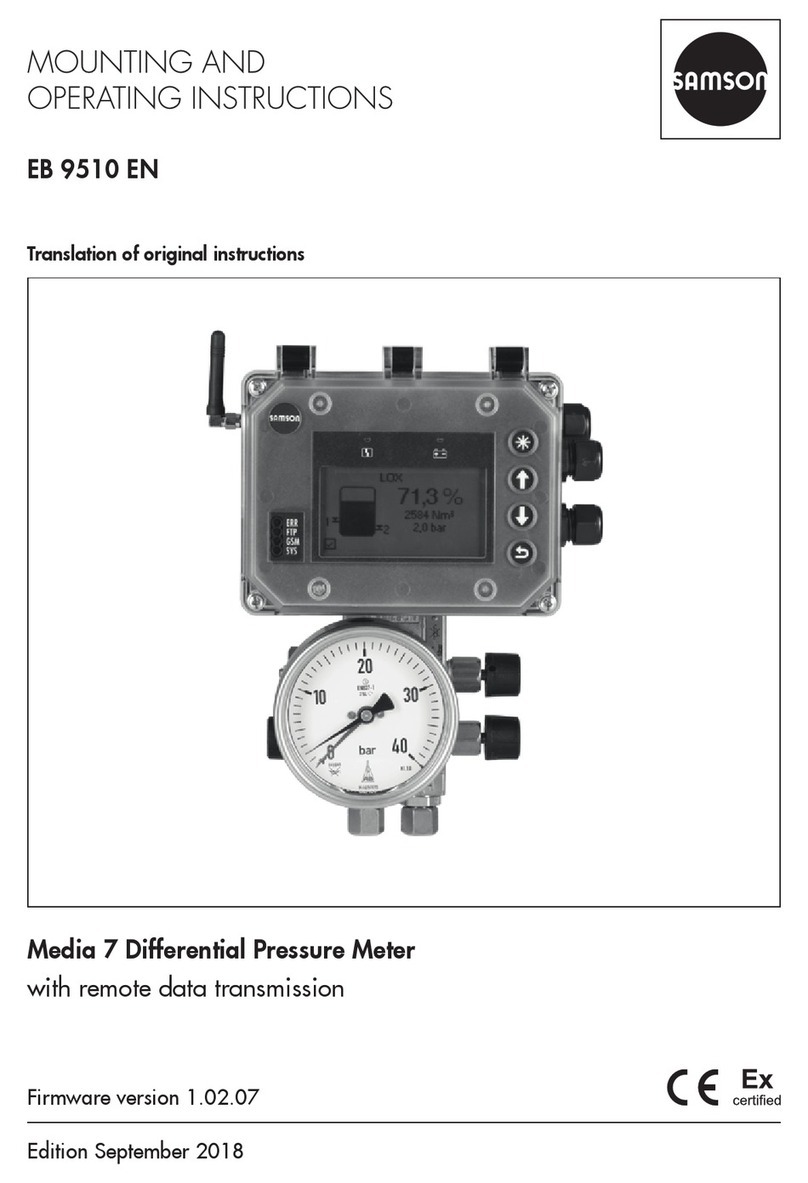

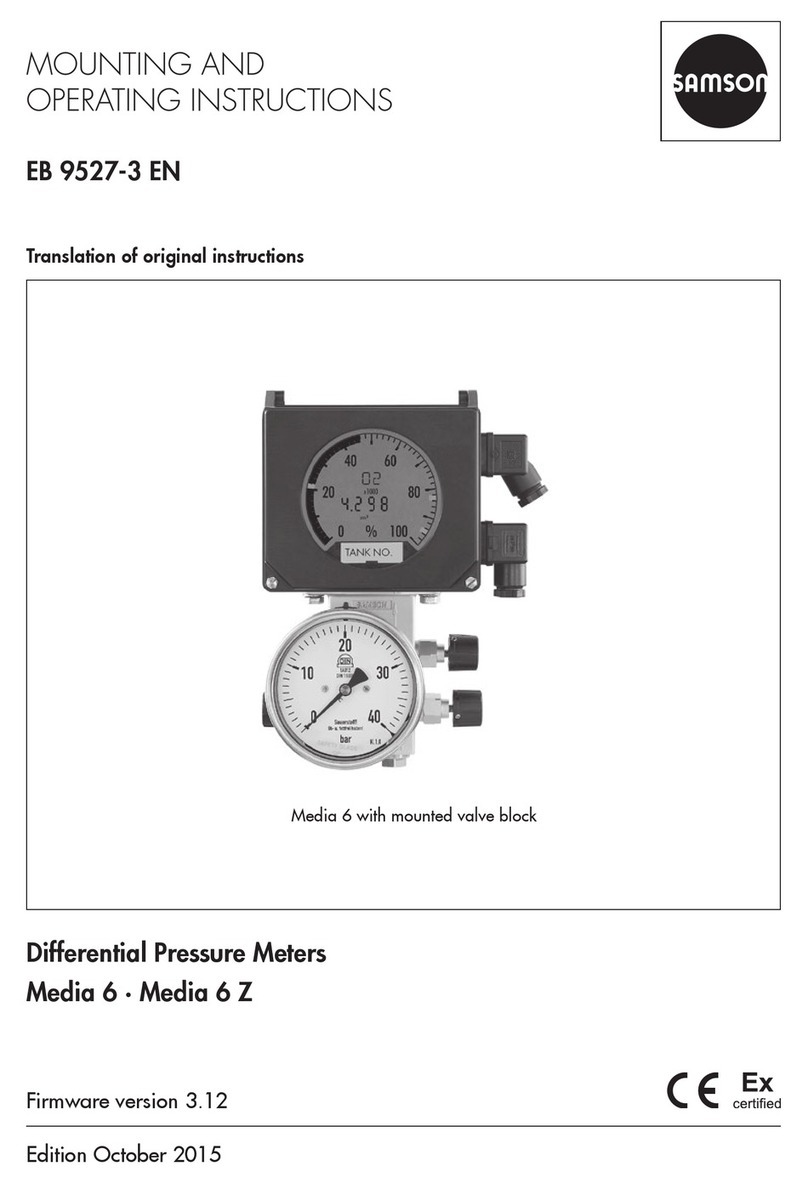

These instructions describe the operation and setting of the Media6 Differential Pressure Me-

ter on the TROVIS-VIEW4 operator interface.

Refer to Mounting and Operating Instructions uEB9527-3 for a description of the Media6

Differential Pressure Meter.

Refer to the Operating Instructions uEB6661 on how to use the TROVIS-VIEW4 software.

The TROVIS-VIEW4 software allows users to congure and parameterize various smart

SAMSON devices (in this case, the Media6 Differential Pressure Meter) over a common user

interface. It consists of the operator interface, communication server, and the device-specic

module. It is possible to switch languages during operation (currently, English, German,

French, Spanish, Japanese, Russian, Danish available). Working in TROVIS-VIEW is similar

to working in Windows Explorer.

In addition to conguration and operation, the TROVIS-VIEW4 software includes other fea-

tures, such as documentation of the Media6 device, for example, editing plant texts, saving

and printing conguration data.

Almost the entire conguration of a Media6 device can be performed using the software.

The user level set to 'Maintenance technician' is used to congure the device. This level is set

by default and can be changed.

The TROVIS-VIEW4 software allows operation in ofine mode (device not connected to a

PC) or in online mode (device connected to a PC). This enables data to be changed in the de-

vice immediately, or they can be saved on the computer rst and downloaded later to the de-

vice on site.

Each smart SAMSON device has its own separate module that contains the device-specic

specications.

1.1 General

TROVIS-VIEW4 and the Media6 device are supplied with default data for lling level mea-

surement, in cases where no specications have been made by the customer.

Newly created data data can be saved to a le, which can be opened at anytime. A stored

TROVIS-VIEW le (*.tro) contains the conguration data and parameters of one single device

and can be transferred to the Media6 device after it has been connected to the computer.

Settings and readings of the software are described in these instructions.