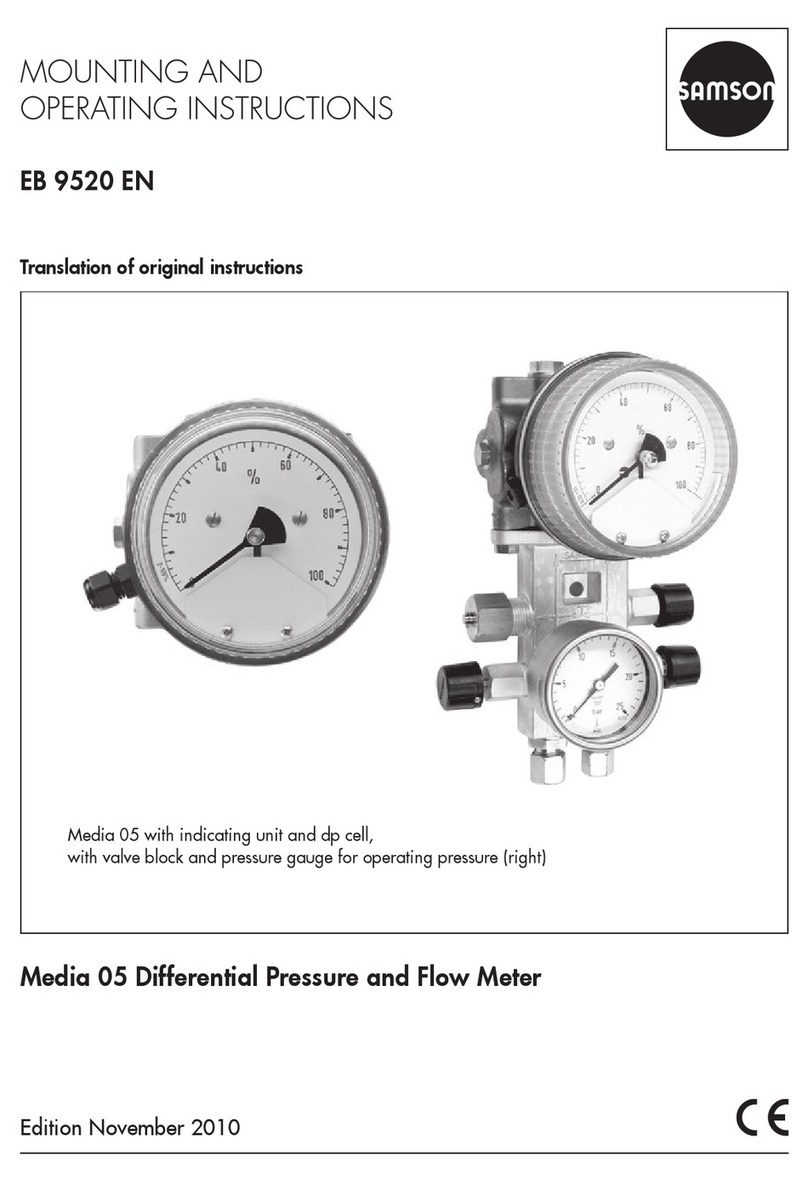

1 Design and principle of operation

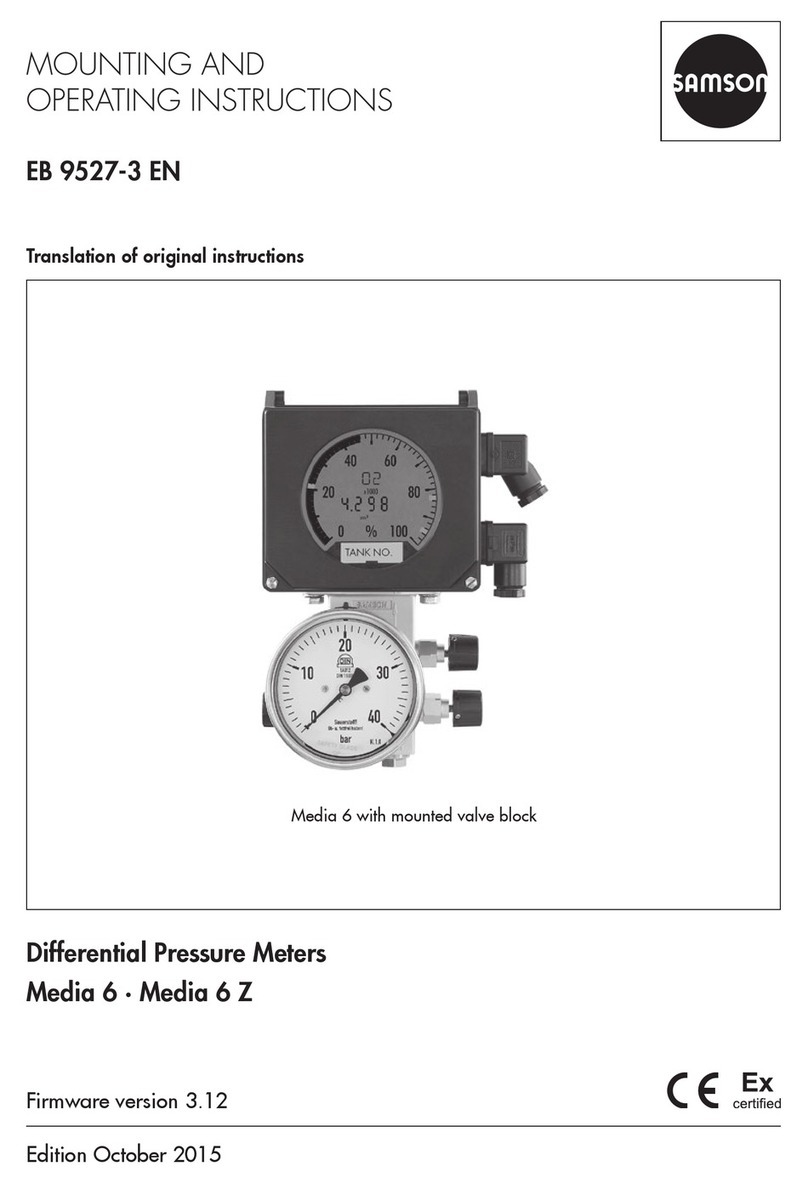

The Media 6 Differential Pressure Meters are

used to measure and indicate differential

pressure as well as derived measured

variables for gases and liquids.

Measuring tasks

–Liquid level measuring on pressure ves-

sels, particularly suitable for cryogenic

liquefied gases

–Differential pressure measuring between

flow and return flow pipe

–Pressure drop measuring on valves and

filters

– Flow rate measuring based on differential

pressure method

The device consists of the dp cell with measur-

ing diaphragm, measuring springs that

match the measuring range as well as the in-

dicating unit equipped with an LCD to indi-

cate certain operating states.

The differential pressure Δp=p

1–p

2gener-

ates a force on the measuring dia-

phragm (1.1), which is balanced by the mea-

suring springs (1.2). The movement of the

measuring diaphragm and lever (1.3), which

is proportional to the differential pressure, is

led out of the pressure chamber over the elas-

tic disc (1.4) and converted into an electric

signal by the travel sensor (2).

Evaluating the data saved in the FRAM (4),

the electric signal is processed by a micropro-

cessor (3). The microprocessor controls both

the display (7) and D/A converter (9) for the

output signal, which is issued asa4to20mA

two-wire transmitter signal at connector A.

The serial interface (10) allows the device to

be configured with the help of SAMSON's

TROVIS-VIEW Configuration and Operator

Interface using a special memory pen or a ca-

ble connection to a PC.

The user-specific data are saved in the mem-

ory (FRAM) (4) until they are overwritten

again. Data can also be backed up. As a re-

sult, the operating data can easily be ex-

changed on site between Media 6 and the

memory pen, and vice versa.

The memory pen can be programmed using a

PC and SAMSON's TROVIS-VIEW software.

The operating data allow the differential

pressure to be converted into values propor-

tional to the tank capacity or flow rate1); these

values are displayed or issued asa4to

20 mA DC signal.

Using the DIP switches (6), four saved gas

types and different write protection functions

for saved data can be selected.

Three operating keys (5) are used to adjust

different operating functions (zero and span

adjustment, filling limit during operation, limit

switch and test function settings etc.) as well

as set different operating states (load or save

operating values).

8EB 9527-3 EN

Design and principle of operation

1) Count pulses in Media 6 Z