8 EB 9520 EN

Design and principle of operation

2 Design and principle of

operation

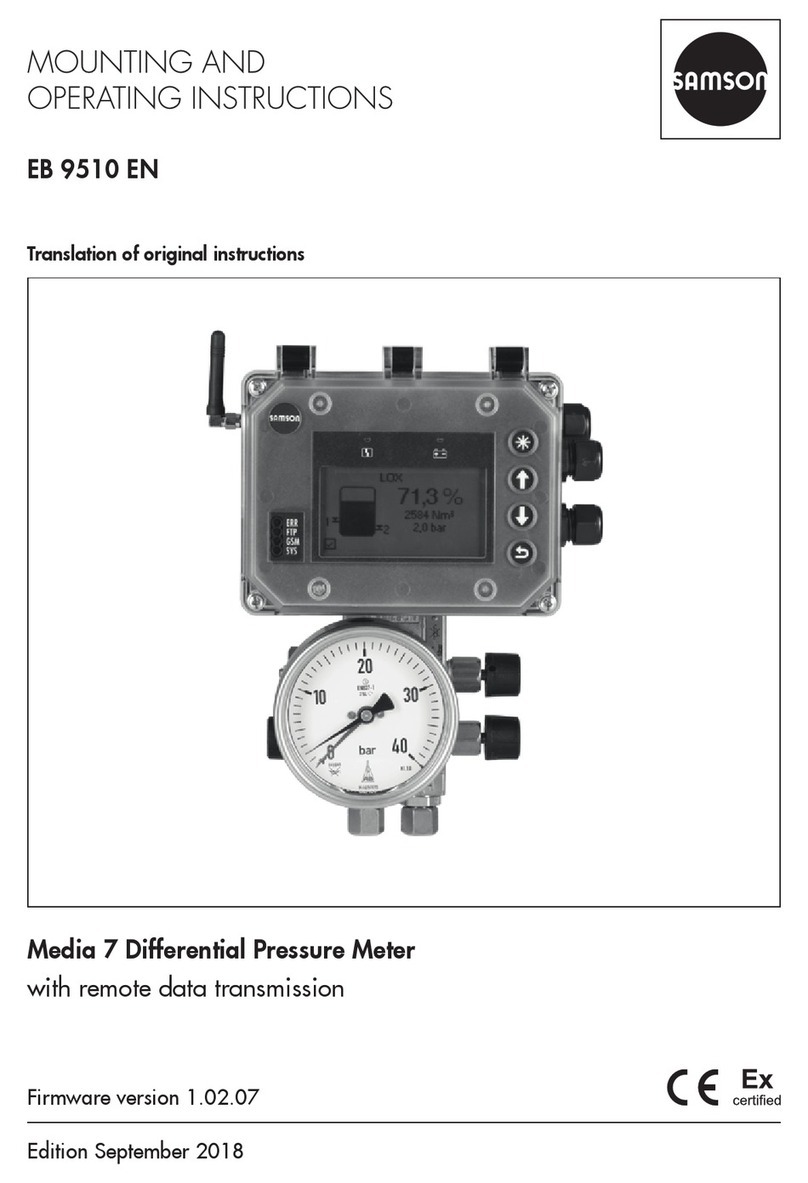

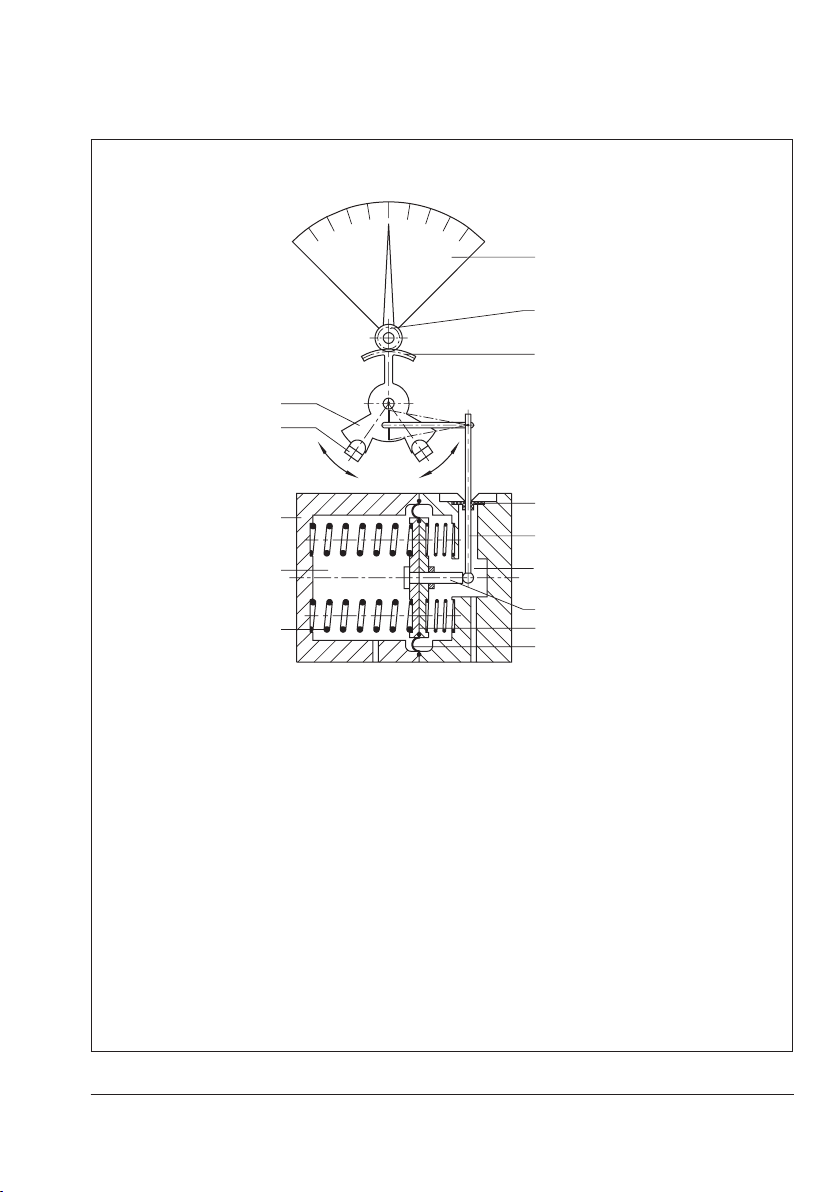

The Media 05 Differential Pressure and Flow

Meter is used to measure and indicate the

differential pressure or derived measuring

variables for gases and liquids. Typical

application include liquid level measurement

on pressure vessels, differential pressure

measurementbetweenowandreturnow

pipes, pressure drop measurement on valves

andltersaswellasowratemeasurement

according to the differential pressure

method.

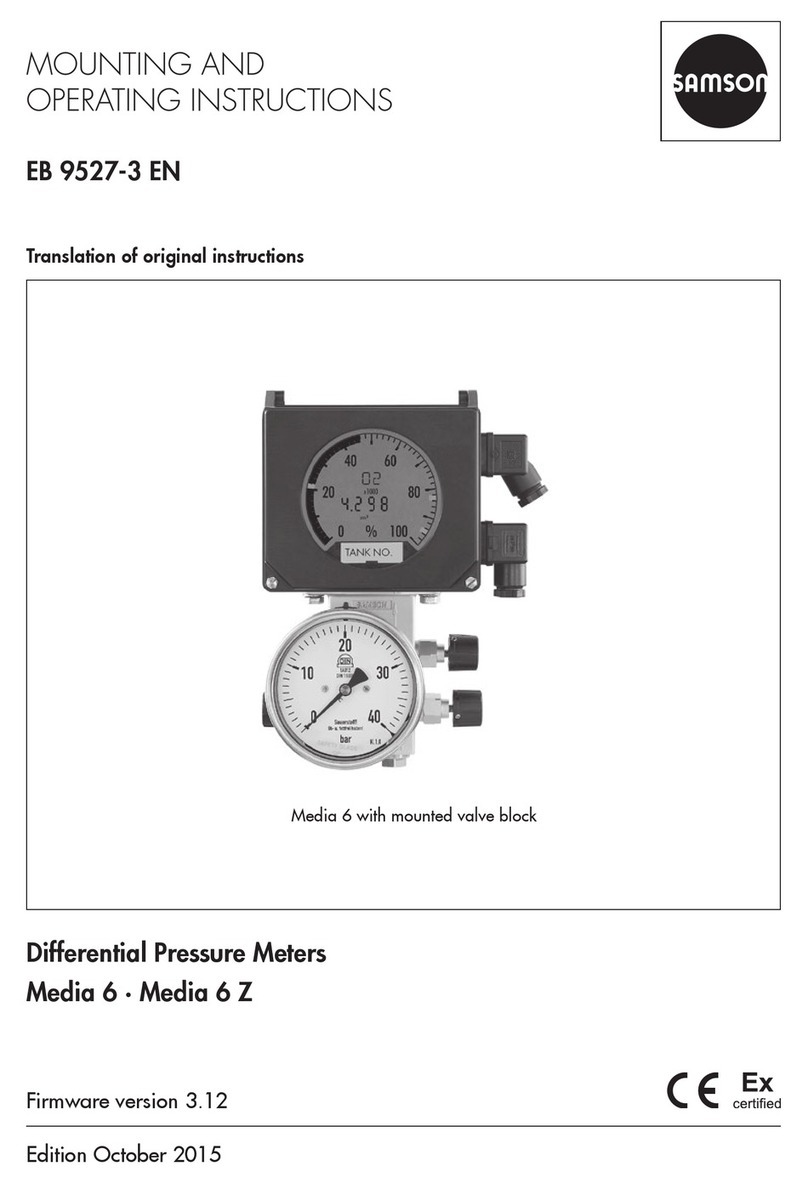

The device comprises a differential pressure

cell including a measuring diaphragm and

range springs as well as an indicating unit

including a pointer mechanism and dial

plate.

Thedifferentialpressure∆p=p1–p2

producedattheoriceplatecreatesaforce

at the measuring diaphragm (1.5), which is

opposed by the range springs (1.4).

The movement of the measuring diaphragm

and lever (1.8), which is proportional to the

differential pressure, is routed from the pres-

surechamberbyaexibledisk(1.9)and

transmitted to the pointer mechanism (2.2).

The differential pressure is shown linear on

thedialandtheowrateisshownasa

square root graduation.

Version with limit contacts

The gear segment (2.1) supports the metal

tags (3.1) and activates the alarm contacts

by moving the metal tags into the adjustable

proximity switches (3.2).

Whenthemetaltagenterstheinductiveeld

of the associated proximity switch, it as-

sumes a high resistance (contact open).

When the metal tag leaves the inductive

eld,itassumesalowresistance(contact

closed).

The switching function is triggered when the

metal tag leaves or enters the proximity

switches (depending on the setting of the

contacts).