Contents

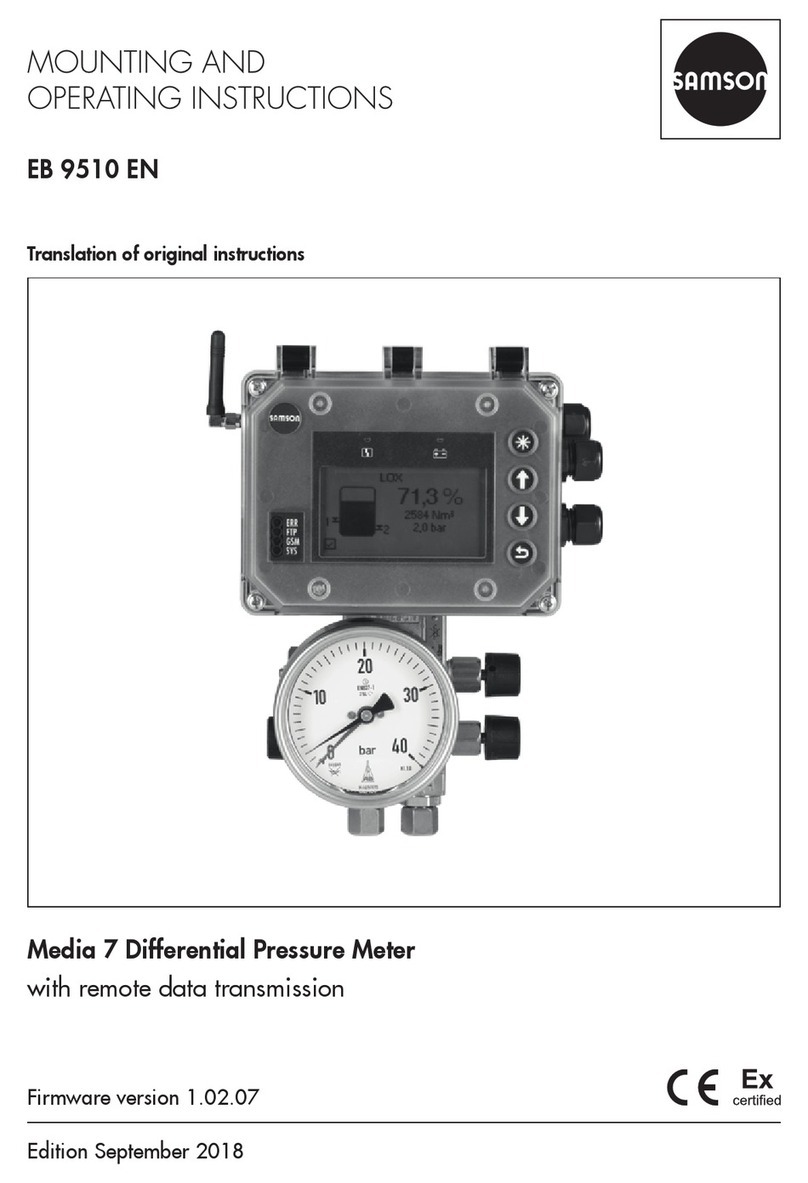

EB 9510 EN

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1-4

1.2 Notes on possible personal injury ................................................................1-6

1.3 Notes on possible property damage.............................................................1-7

2 Markings on the device ..............................................................................2-1

2.1 Nameplate .................................................................................................2-1

2.2 Label on devices for oxygen service..............................................................2-2

2.3 Firmware versions.......................................................................................2-3

2.4 Article code................................................................................................2-4

3 Design and principle of operation ...............................................................3-1

3.1 CongurationusingtheTROVIS-VIEWsoftware ............................................3-1

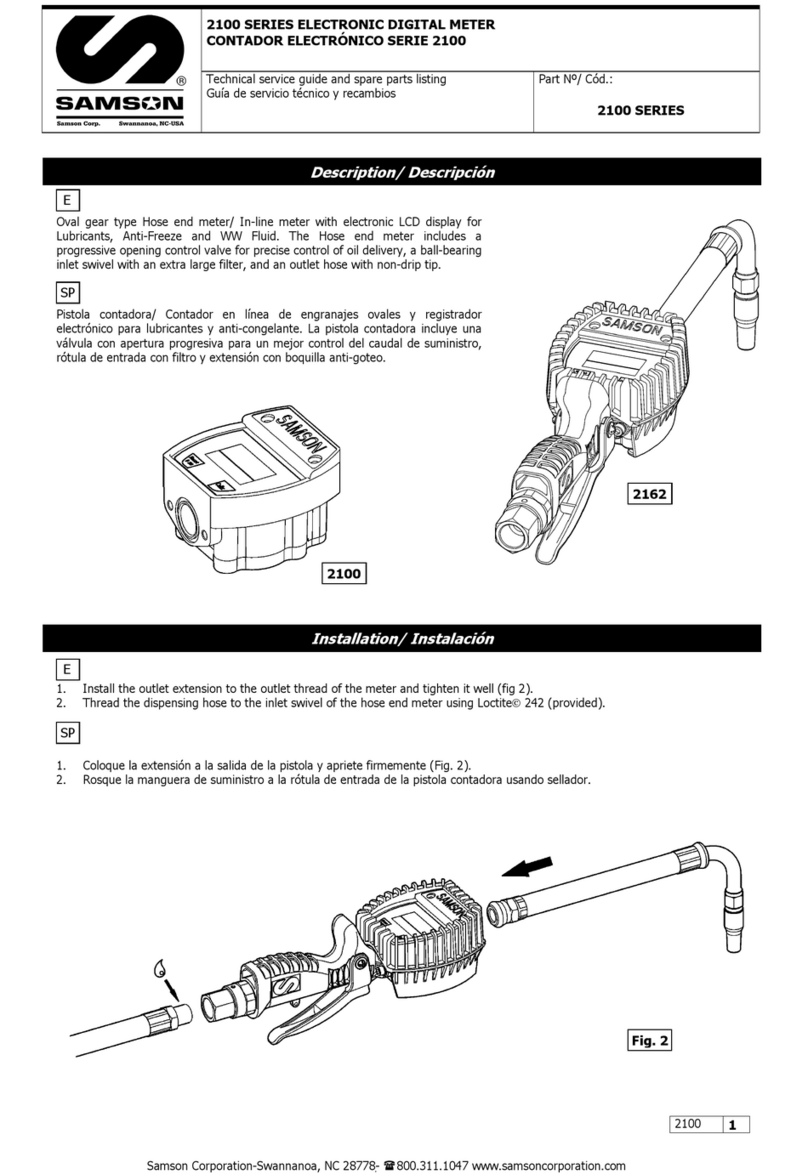

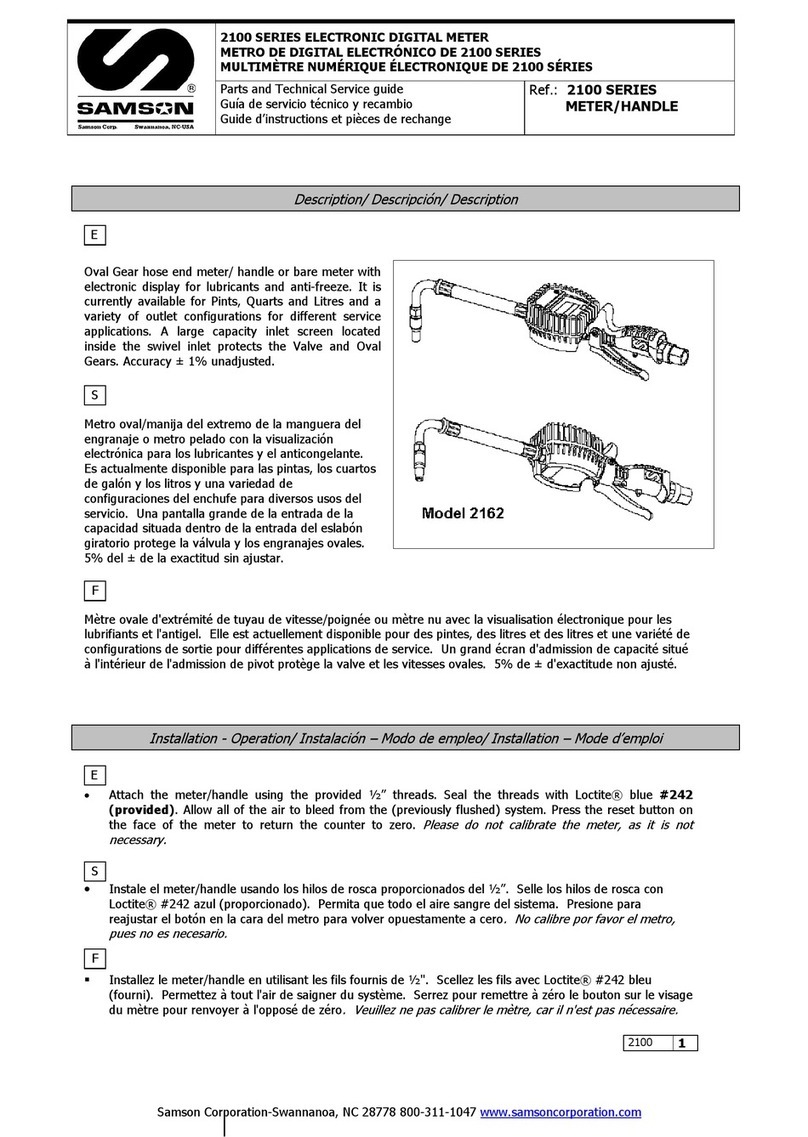

3.2 Versions .....................................................................................................3-4

3.2.1 Two-wire version.........................................................................................3-4

3.2.2 24Vversion...............................................................................................3-4

3.2.3 230Vversion.............................................................................................3-4

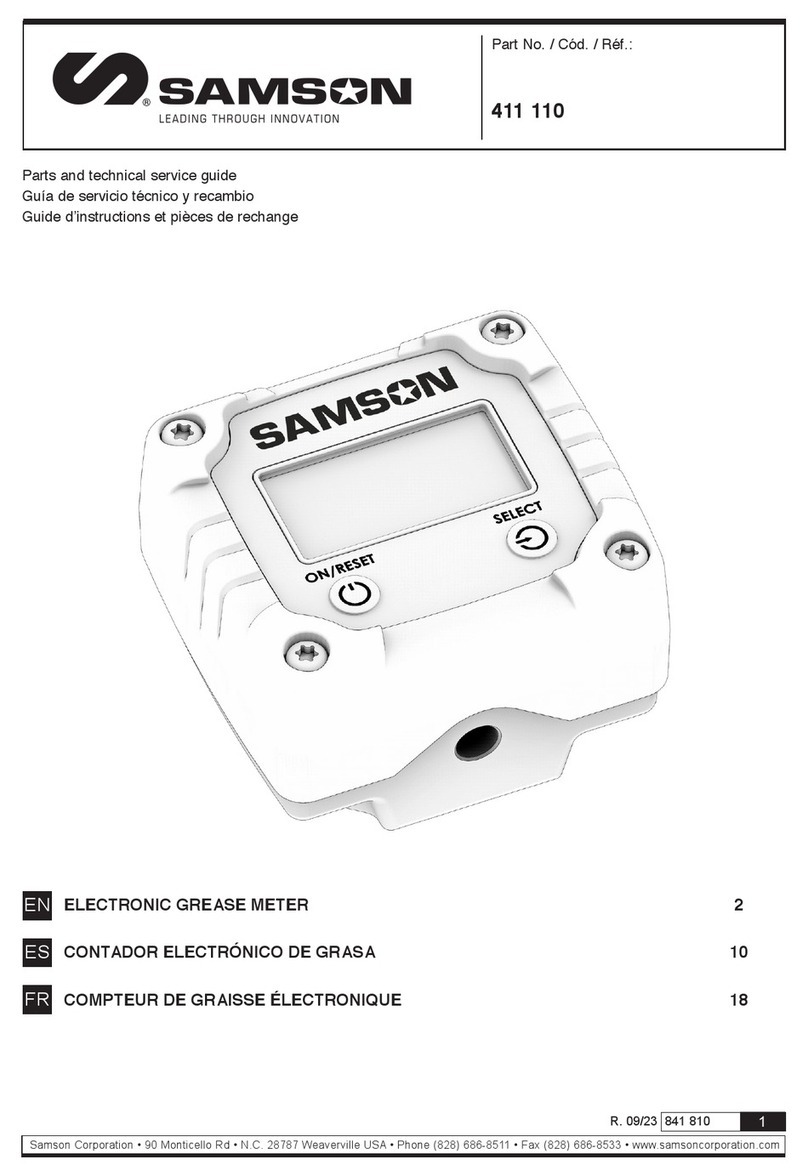

3.3 Device overview and operating controls........................................................3-4

3.4 Optional additional function ........................................................................3-6

3.4.1 Option modules..........................................................................................3-6

3.4.2 GSM module..............................................................................................3-6

3.4.3 Power supply unit with standby power supply (SPS) .......................................3-6

3.5 Technical data ............................................................................................3-8

3.6 Dimensions in mm.....................................................................................3-13

3.6.1 Dimensions for mounting (mm)...................................................................3-14

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removingthepackagingfromthedifferentialpressuremeterandmodules ......4-1

4.3 Transporting the differential pressure meter ...................................................4-1

4.4 Storing the differential pressure meter...........................................................4-1

5 Installation.................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-1

5.3 Setting up the optional additional functions...................................................5-2

5.3.1 Inserting option modules..............................................................................5-4

5.3.2 Inserting the GSM module ...........................................................................5-6

5.3.3 Setting up the standby power supply (SPS)....................................................5-8