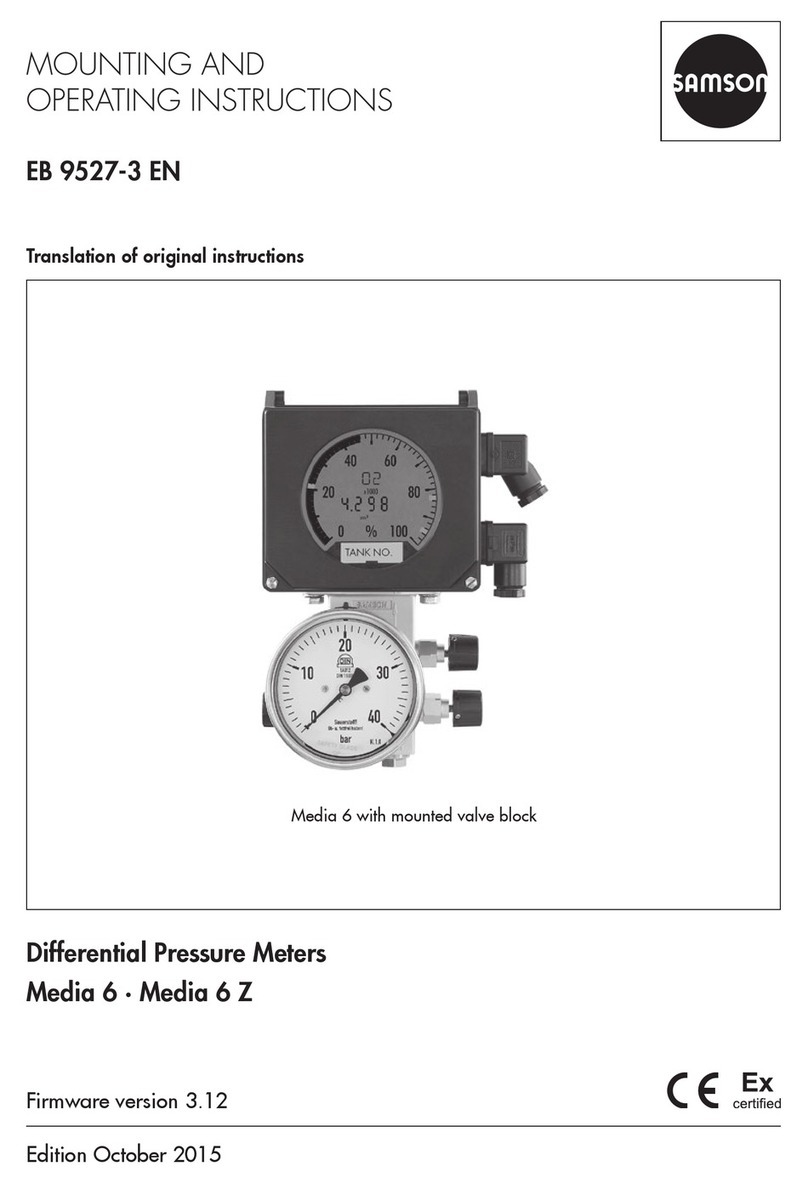

1 Design and principle of operation

The Media 6 Differential Pressure Meters

measure and indicate the differential pres-

sure or measured variables derived from

the differential pressure. They are designed

for gases and liquids, for example, for liq-

uid level measurement in pressurized

vessels.

The measuring device consists of a dp cell

and an indicating unit. The cell has a

measuring diaphragm and measuring

springs designed for a certain measuring

span, and the indicating unit is equipped

with either an LCD (liquid crystal display) or

an LED (light-emitting diode) to indicate

important operating conditions.

The differential pressure ∆p = p1– p2acts

on the measuring diaphragm (1.1) which is

counterbalanced by the measuring springs

(1.2). The movement made by the measur-

ing diaphragm and lever (1.3) which is pro-

portional to the differential pressure is led

by the elastic disc (1.4) out of the pressure

chamber and converted by the displace-

ment sensor (2) into an electric signal.

This signal is compared with the data stored

in the EEPROM (4) and processed in the

microprocessor (3) which controls both the

display (7, LCD or LED) and the D/A con-

verter (9) for the output signal which is is-

sued at connector Aas a two-wire 4 to

20 mA transmitter signal.

The SERIAL INTERFACE (10) enables the

device to be configured using a special

memory pen or a connecting cable and a

PC with SAMSON’s TROVIS-VIEW Configu-

ration and Operator Interface.

The user-specific data is saved in the

EEPROM (4). Data can also be saved in this

manner and kept until it is overwritten

again. The operating data of Media 6 can

also be uploaded to the memory pen and

downloaded to the device on site.

The memory pen can be programmed on a

PC with the corresponding TROVIS-VIEW

software, using the operating data, e.g.

type of gas, gas density, tank design and

position of the limit switches. This data is

used to convert the differential pressure into

a value proportional to the tank contents

then used to display and issue the direct cur-

rent signal from 4 to 20 mA.

Four types of gas and various write protec-

tion functions for stored data can be se-

lected using the DIL switches (6).

Several operating functions (zero and span

calibration, filling limit during operation,

limit switches and test function settings, etc.)

as well as operating status (load/save oper-

ating values) can be set using three keys (5).

6EB 9527-1 EN

Design and principle of operation