-V -

Table of Contents

PRIOR TO USE............................................................................................................................................................................. Ⅰ

SAFETY SYMBOLS..................................................................................................................................................................... Ⅰ

SAFETY CAUTIONS................................................................................................................................................................... Ⅱ

REVISION HISTORY.................................................................................................................................................................. Ⅳ

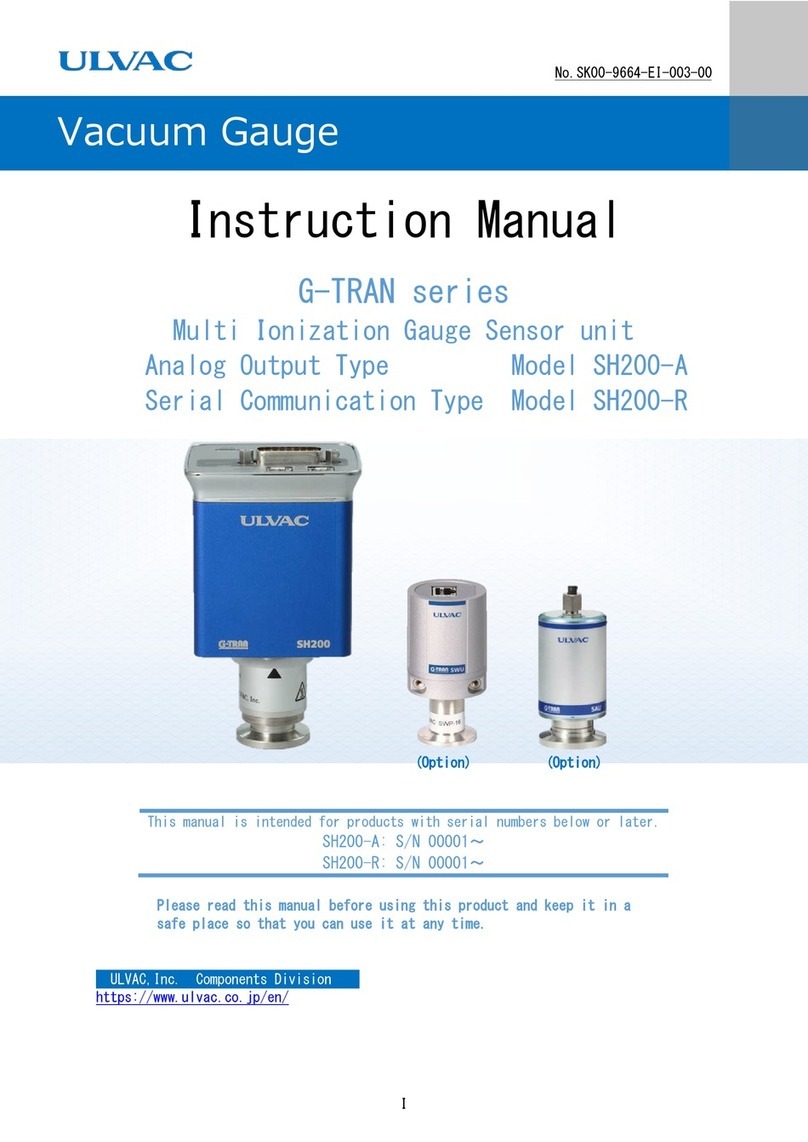

1. GENERAL DESCRIPTION ............................................................................................................................................... 1

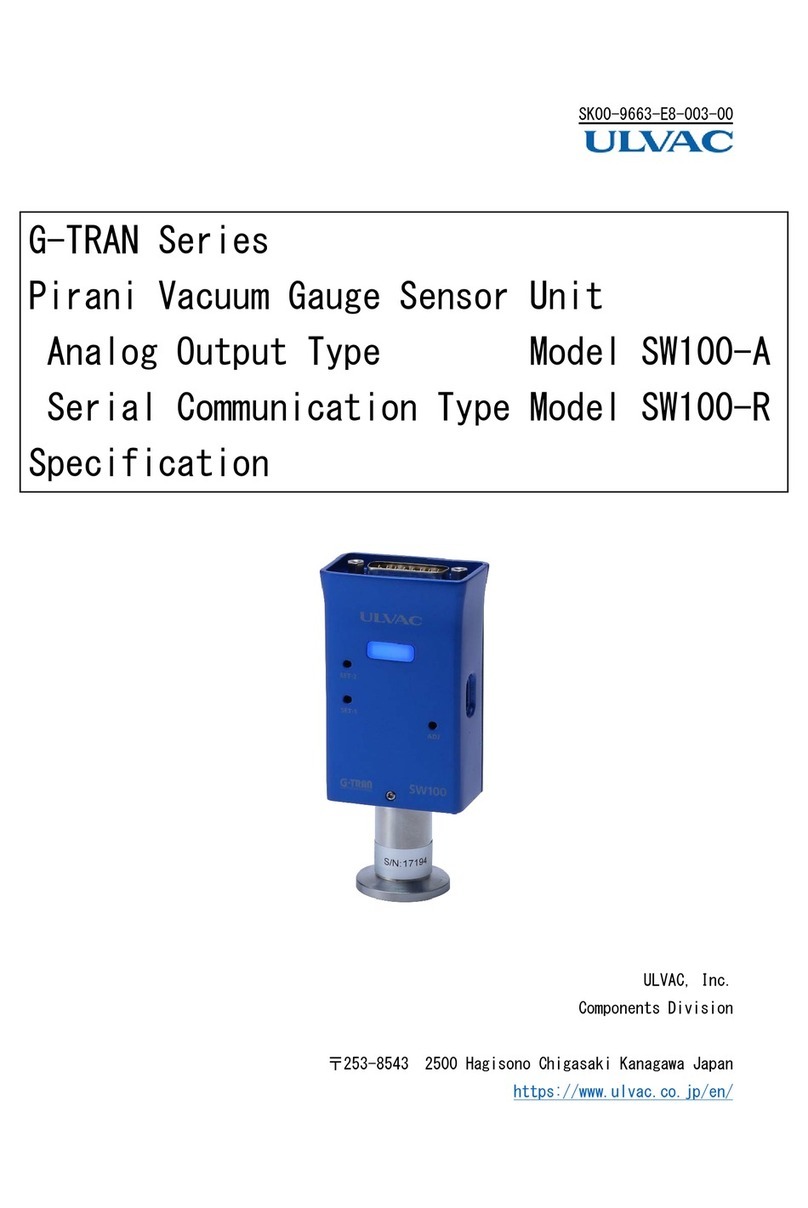

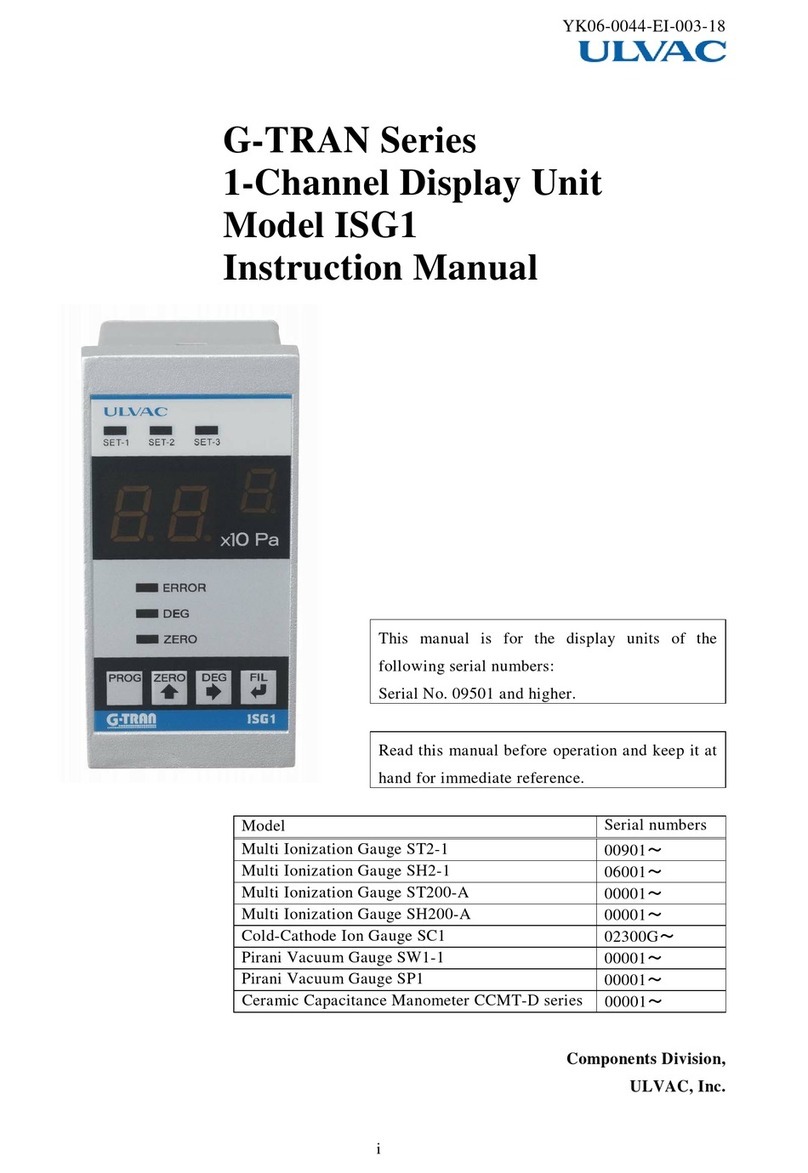

1.1. SPECIFICATIONS .............................................................................................................................................................. 1

1.2. STANDARD ACCESSORIES............................................................................................................................................... 1

1.3. OPTION ............................................................................................................................................................................. 2

1.3.1. Sensor head............................................................................................................................................................... 2

1.3.2. Measuring unit......................................................................................................................................................... 2

1.3.3. Sensor head cable.................................................................................................................................................... 2

1.3.4. Supply cable 3m(only GP-2001G).................................................................................................................. 2

1.3.5. Others.......................................................................................................................................................................... 2

1.4. DESCRIPTION OF COMPONENTS................................................................................................................................... 3

1.4.1. Front panel................................................................................................................................................................ 3

1.4.2. Rear Panel .................................................................................................................................................................4

2. INSTALLING THE PIRANI VACUUM GAUGE ...................................................................................................... 5

2.1. PRELIMINARY OPERATION ............................................................................................................................................ 5

2.2. INSTALLATION .................................................................................................................................................................5

2.2.1. Installing the controller.......................................................................................................................................... 5

2.2.2. Installing the sensor head..................................................................................................................................... 6

2.2.3. Installing the supply cable .................................................................................................................................... 7

2.2.4. Electrical connection................................................................................................................................................ 7

2.2.5. A sensor head installation method to GP-H................................................................................................... 9

3. OPERATING PROCEDURE ...........................................................................................................................................10

3.1. CAUTIONS IN HANDLING.............................................................................................................................................10

4. OPERATING PROCEDURE ...........................................................................................................................................11

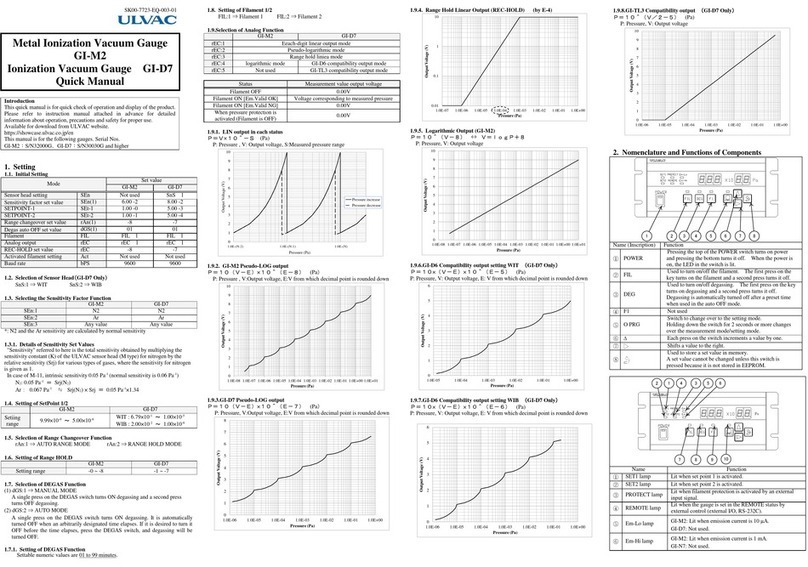

4.1. SUMMARY OF THE OPERATION METHOD ..................................................................................................................11

4.2. SELECTING THE RECORDER OUTPUT .......................................................................................................................12

4.3. SELECTING THE UNIT OF PRESSURE ........................................................................................................................12

4.4. DISPLAY AND CHANGE OF SETPOINT COMPARISON VALUE ................................................................................12

4.5. ADJUSTING THE RECORDER OUTPUT .......................................................................................................................13

4.6. RECORDER OUTPUT......................................................................................................................................................14

4.7. SETPOINT OUTPUT .......................................................................................................................................................16

4.8. ZERO RESETTING FUNCTION......................................................................................................................................16

5. APPENDIX ............................................................................................................................................................................17

5.1. PRINCIPLES OF OPERATION ........................................................................................................................................17

5.2. TYPES OF GAS MEASURED AND INDICATION ..........................................................................................................18

5.3. CHANGE OF INDICATION WITH AMBIENT TEMPERATURE ....................................................................................20

6. TROUBLESHOOTING......................................................................................................................................................21

7. WARRANTY..........................................................................................................................................................................23

8. CHINA ROHS DECLARATION ....................................................................................................................................24

9. CERTIFICATE OF DECONTAMINATION...............................................................................................................25

10. RELATED DRAWINGS ...............................................................................................................................................26