SATO GT424 User manual

GT Series

OPERATOR’SMANUAL

SATO ASIA PACIFIC PTE. LTD.

438A ALEXANDRA ROAD

#05-01/02 ALEXANDRA TECHNOPARK

SINGAPORE 119967

Tel: (65) 6271 5300

Fax: (65) 6273 6011

Sales Hotline: (65) 6276 2722

Service Hotline: (65) 6273 6455

Email: sales@satoasiapacific.com

Website: www.satoworldwide.com

Copyright 2003

SATO Asia Pacific Pte. Ltd.

Warning : This equipment complies with the requirements in Part 15 of FCC rules for a

Class A computing device. Operation of this equipment in a residential area may cause

unacceptable interference to radio and television reception requiring the operator to take

whatever steps necessary to correct the interference. All rights reserved. No part of this

document may be reproduced or issued to third parties in any form whatsoever without

the express permission of SATO Asia PacificPte. Ltd. The materials in this document are

provided for general information andare subjected to change without prior notice. SATO

Asia Pacific Pte. Ltd. assumes no responsibilities for any errors that may appear.

i

TABLE OF CONTENTS

1OVERVIEW

1.1 General Specifications .................................................................................1-2

2 INSTALLATION

Safety Precautions.....................................................................................................2-2

2.1 Unpacking......................................................................................................2-4

2.1.1 Included Accessories......................................................................................2-5

2.1.2 Parts Identification ..........................................................................................2-6

2.2 Loading the Carbon Ribbon.........................................................................2-10

2.2.1 Removing the Carbon Ribbon ........................................................................2-11

2.2.2 OPTION: Using A Paper Tube to Wind Used Ribbon ....................................2-12

2.3 Loading Labels And Tags ............................................................................2-13

2.3.1 Loading Roll Paper ......................................................................................2-14

2.3.2 Loading Fanfold Paper ...................................................................................2-17

2.3.3 Loading Fanfold Paper under the printer .......................................................2-19

2.3.4 Adjusting the paper sensor ............................................................................2-21

2.4 Replacing the Print Head..............................................................................2-22

2.5 Turning the printer ON/OFF .........................................................................2-23

3 CONFIGURATION AND OPERATION

3.1 Operating Modes...........................................................................................3-1

3.2 The Operation Panel.....................................................................................3-2

3.3 Screen Icons And Their Meaning ................................................................3-3

3.4 ONLINE And OFFLINE Modes......................................................................3-5

3.4.1 Online Mode ...................................................................................................3-5

3.4.2 Offline Mode ...................................................................................................3-5

3.5 User Mode......................................................................................................3-6

3.5.1 Entering User Mode .......................................................................................3-6

3.5.2 Setting Buzzer Volume, Print Pitch, Print Offset, Print Darkness ...................3-7

3.5.2 Setting Print Speed ........................................................................................3-7

3.5.3 Setting Print Darkness ....................................................................................3-8

3.5.4 Setting Print Offset .........................................................................................3-8

3.5.5 Setting Zero Slash Changeover .....................................................................3-9

3.5.6 Setting JIS Kanji Code Changeover* .............................................................3-9

3.5.7 Setting Kanji Font Style* ................................................................................3-9

3.5.7 Setting Proportional Pitch ..............................................................................3-10

3.6 Interface Mode...............................................................................................3-11

3.6.1 Entering Interface Mode .................................................................................3-11

3.6.2 Enabling Interface Card Configuration ...........................................................3-11

3.6.3 Assigning An Interface Card For Printing .......................................................3-12

3.6.4 Selecting The Data Input Port ........................................................................3-12

3.6.5 Enabling or Disabling The Status Return Port ...............................................3-12

ii

3.7 Cartridge Mode..............................................................................................3-13

3.7.1 Entering Cartridge Mode ................................................................................3-13

3.7.2 Cartridge Formatting Option ...........................................................................3-13

3.7.3 Start Cartridge Formatting ..............................................................................3-13

3.7.4 Cartridge Formatting Progress .......................................................................3-14

3.8 SEMBL Mode .................................................................................................3-15

3.8.1 Entering SEMBL Mode ...................................................................................3-15

3.8.2 Selecting The Start Program ..........................................................................3-15

3.8.3 The SEMBL Status Screen ............................................................................3-16

3.9 Advanced Mode.............................................................................................3-17

3.9.1 Entering Advanced Mode ...............................................................................3-17

3.9.2 Selecting The Print Density ............................................................................3-17

3.9.3 Setting the Automatic Detection of Optional Units ........................................3-17

3.9.4 Choosing Continuous or Tear Off Operation ..................................................3-18

3.9.5 Backfeed Operation Settings ..........................................................................3-18

3.9.6 Configuring the Internal Winding Unit .............................................................3-18

3.9.7 Setting the Print Mode ....................................................................................3-19

3.9.8 Configuring the Paper Sensor ........................................................................3-19

3.9.9 Configuring the Paper Sensor Type ...............................................................3-19

3.9.10 Turning Head Check Function ON/OFF .........................................................3-20

3.9.11 Choosing the Type of Head Check ............................................................3-20

3.9.12 Enabling/Disabling External Signal Output .....................................................3-21

3.9.13 Selecting the Type of External Signal Output .................................................3-21

3.9.14 Selecting Reprint via External Signal Output .................................................3-21

3.9.15 Using the Auto Online Feature .......................................................................3-22

3.9.16 Enabling Auto Feed ........................................................................................3-22

3.9.17 Enabling Auto Feed On Error .........................................................................3-22

3.9.18 Specifying the Protocol Code Format .............................................................3-23

3.9.19 Specifying The SEMBL Start Mode ................................................................3-23

3.9.20 Specifying The SEMBL Auto Start Program ...................................................3-23

3.10 HEX Dump Mode ...........................................................................................3-24

3.10.1 Entering HEX Dump Mode .............................................................................3-24

3.10.2 Selecting Data To Dump ................................................................................3-24

3.10.3 Controlling the Hex Dump Mode ....................................................................3-24

3.11 Test Print Mode .............................................................................................3-25

3.11.1 Entering Test Print Mode ................................................................................3-25

3.11.1 Choosing What The Test Print Contains ........................................................3-25

3.11.2 Setting Test Print Width for Configuration, Barcode and Head Check ..........3-26

3.11.3 Setting the Size of the Factory Test Print .......................................................3-26

3.11.4 Starting the Test Print .....................................................................................3-26

3.12 Overview of All Modes..................................................................................3-27

3.13 Restoring Factory DeFault Settings ............................................................3-37

3.13.1 Entering Default Mode ....................................................................................3-37

3.13.2 If You Chose to Reset Printer Settings ...........................................................3-38

3.13.2 If You Chose Alt Protocol Code ......................................................................3-38

3.13.3 Completion of Default Setting .........................................................................3-38

3.14 Understanding Continuous Print and Tear Off Operations.......................3-39

iii

4 CLEANING AND MAINTENANCE

4.1 Introduction...................................................................................................4-1

4.2 Cleaning The Print Head, Platen and Rollers.............................................4-1

4.3 How To Clean The Printer (Cleaning SET)..................................................4-2

4.4 How To Clean The Printer (Cleaning SHEET).............................................4-3

4.5 Adjusting Print Quality.................................................................................4-4

4.5.1 Adjusting Print Darkness 4-4

4.5.2 Adjusting Print Speed 4-5

5 INTERFACE SPECIFICATIONS

5.1 Interface types...............................................................................................5-1

5.2 Interface Card DIP SWITCH Settings (RS-232C) ........................................5-2

5.3 Interface Card DIP SWITCH Settings (LAN)................................................5-3

5.4 Interface Card DIP SWITCH Settings (Wireless LAN)................................5-3

5.5 Interface Card DIP SWITCH Settings (Mini LAN)........................................5-4

5.6 Serial Interface SPECIFICATIONS (RS-232C).............................................5-5

5.7 READY/BUSY ................................................................................................5-6

5.8 Single Job Buffer ..........................................................................................5-7

5.9 Multi Job Buffer.............................................................................................5-8

5.10 X-ON/X-OFF ...................................................................................................5-8

5.11 Single Job Buffer ..........................................................................................5-10

5.12 Multi Job Buffer.............................................................................................5-11

5.13 Driver Protocol..............................................................................................5-11

5.14 Status 3..........................................................................................................5-24

5.15 Multi Job Buffer.............................................................................................5-25

5.16 Reference Flowchart.....................................................................................5-32

5.17 Parallel Interface SPECIFICATIONS (Centronics)......................................5-33

5.18 Single Job Buffer ..........................................................................................5-35

5.19 Multi Job Buffer.............................................................................................5-37

5.20 IEEE 1284 Interface.......................................................................................5-39

5.21 Interface Signals ...........................................................................................5-42

5.22 Single Job Buffer ..........................................................................................5-43

5.23 Multi Job Buffer.............................................................................................5-45

5.24 Driver Protocol..............................................................................................5-47

iv

TROUBLESHOOTING

6.1 Initial Checklist..............................................................................................6-1

6.2 Using the Centronics (Parallel) Interface....................................................6-1

6.3 Using the RS232C (SERIAL) Interface.........................................................6-3

6.4 Understanding the STATUS INDICATORS..................................................6-4

6.5 Understanding the LCD Error Messages....................................................6-5

6.6 LCD Warning Messages ...............................................................................6-10

6.7 Troubleshooting Guide.................................................................................6-11

OPTIONAL ACCESSORIES

7.1 Introduction ...................................................................................................7-1

7.2 Available Interface Boards...........................................................................7-1

7.3 Label Management Accessories..................................................................7-2

7.3 PCMCIA Memory Cartridge ..........................................................................7-3

7.3.1 Installing the memory card..............................................................................7-3

Section 1: Introduction

GT Series Operator’s Manual Page 1-1

1

OVERVIEW

Thank you for your investment in this SATO printer product.

This Operator’s Manual contains basic information about the installation, setup,

configuration, operation and maintenance of the printer.

A total of seven topics are covered herein, and they are organized as follows:

Section 1: Overview

Section 2: Installation

Section 3: Configuration and Operation

Section 4: Cleaning and Maintenance

Section 5: Interface Specifications

Section 6: Troubleshooting

Section 7: Optional Accessories

It is recommended that you become familiar with each section before installing and main-

taining the printer. Refer to the Table Of Contents at the front of this manual to search

for the relevant information needed. All page numbers in this manual consist of a section

number followed by the page number within the stated section.

For specialized programming, refer to the separate Programming Manual located on the

utility CD-ROM.

Section 1: Introduction

Page 1-2 GT Series Operator’s Manual

1.1 GENERAL SPECIFICATIONS

The SATO GT4xx “e” series of dual use (Thermal Transfer and Direct Thermal) printers

are complete, high-performance labeling systems designed for printing tags and labels.

The key features of the GT series are:

• Faster print speed and better print quality than ever

• Large 3-line LCD screen and icon-rich user interface

• Fully configurable without the need for setting DIP switches

• Easy operation via multiple control buttons and status indicators

• Easy upgrading to higher resolution print heads and additional memory by users

• Richer SBPL command set for better control via software/network

• Supports standalone operation via execution of BASIC programs stored in memory

• Supports two I/O connections

• User friendly label and ribbon path

• Ribbon saving feature

All printer parameters are programmable using the front panel controls and via software.

All popular bar codes, including 2-D codes, eight human-readable fonts with two Care

Symbol fonts and a fast and efficient vector font, are resident in memory, providing liter-

ally thousands of combinations of type styles and sizes.

Section 1: Introduction

GT Series Operator’s Manual Page 1-3

Features of SATO GT4xxe Series Printers

Feature GT408e GT412e GT424e

Print resolution 203dpi for economical

labeling solution

(user upgradable to higher

resolution print assembly)

305dpi for laser quality

printing and graphic

images

608dpi for laser quality

printing and graphic

images

Print method Thermal Transfer and

Direct Thermal Thermal Transfer and

Direct Thermal Thermal Transfer and

Direct Thermal

Label sizes supported

(using default internal

memory)

4 inches (W) by 9.4 inches 4 inches (W) by 9.4 inches 4 inches (W) by 9.4 inches

Label sizes supported

(using additional

optional PCMCIA

memory card)

4 inches (W) by 49.2 inches

at 203 dpi 4 inches (W) by 32.8

inches at 305 dpi 4 inches (W) by 32.8

inches at 305 dpi

Integral Cutter unit Optional Optional Optional

Stacker option Up to 500 3.9 inch (W) by

5.9 inch labels Up to 500 3.9 inch (W) by

5.9 inch labels Up to 500 3.9 inch (W) by

5.9 inch labels

Interfaces available Optional RS-232C, LAN,

USB, RFID, IEEE 1284 or

high speed RS-232C

Optional RS-232C, LAN,

USB, RFID, IEEE 1284 or

high speed RS-232C

Optional RS-232C, LAN,

USB, RFID, IEEE 1284 or

high speed RS-232C

Section 1: Introduction

Page 1-4 GT Series Operator’s Manual

1.1 GENERAL SPECIFICATIONS (CONT’D)

Specification/

Model Name GT408 GT412 GT424

Print method Thermal transfer or thermal

Head density 8 dots/ mm (203 dpi) 12 dots/ mm (305 dpi) 24 dots/ mm (609 dpi)

Print valid range (width) 104 mm x pitch 2500mm 104 mm x pitch 1500mm 104 mm x pitch 400 mm

Not printable for 3mm from the backside.

Print speed (Max) 12 inches/sec

(Approx 300mm/sec) 12 inches/sec

(Approx 300mm/sec) 6 inches/sec

(Approx 150mm/sec)

Note:

Maximum speed may be further dependent on the type of print layout, paper,

or carbon ribbon in use.

Paper Thickness 0.060 mm to 0.268 mmsupported.

Note:

Be sure to use only printer supplies manufactured or certified bySATO.

Label size

(mounting

and

cardboard

size)

Standard Width: 22 to 128 mm (25 to 131 mm)

Pitch: 5 to 397 mm (9 to 400 mm) Note:

Supported sizes may be

regulated due to the quan-

tity of print jobs or size of

paper.

Other usage conditions

may restrict the range of

label sizes supported.

Tear off Width: 22 to 128 mm (25 to 131 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Peel Width: 22 to 128 mm (25 to 131 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Cutter Width: 22 to 128 mm (25 to 131 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Non-sepa-

rate Width: 22 to 128 mm (25 to 131 mm)

Pitch: 17 to 397 mm (20 to 400 mm)

Number of

loadable

sheets

Roll paper Maximum external diameter:

200 mm (Approximately 150 m/roll) 3-inch paper tube used

Back winding (only front winding for non-separate mode)

Fanfold

paper Maximum folded height: 200 mm

See the section in this manual on Setting Fanfold Paper

Carbon ribbon

Width

Length

Thickness of base material

Color

Winding direction

Be sure to use the specified carbon ribbon manufactured by SATO.

39.5, 45, 59, 76, 84, 92, 102, 111, and 128 mm

Use a carbon ribbon that is wider than the paper used.

300 m/roll

4.5 µm

Black (standard), also red, blue, purple, and green

Front winding and back winding

Label dispensing modes Continuous, tear off, peeler, dispenser and non-separate

Dimensions W 271 mm x D 455 mm x H 305 mm x (Standard)

Weight 14 kg (for a standard configuration)

Power supply Input voltage: AC 100 V to 240 V ±10%

Power consumption: Maximum 200 VA 150 W, print rate 30% (89 VA 40 W on standby)

Operating Environment Operational ambient temperature: 0 to 40 ×C

Operational ambient humidity: 30 to 80% (without condensation)

Storing ambient temperature: -5 to 60 ×C

Storing ambient humidity: 30 to 90% (no condensation)

Paper, and carbon ribbon excluded.

Section 1: Introduction

GT Series Operator’s Manual Page 1-5

1.1 GENERAL SPECIFICATIONS (CONT’D)

Specification/

Model Name GT408 GT412 GT424

External interface Interface board

¤ Parallel (IEEE1284)

¤ RS-232C

• READY/BUSY

• XON/XOFF

• Status 2/3

• Driver specific protocol

• Status 5

¤ USB (Ver. 2.0)

¤ LAN (10BASE-T/ 100BASE-TX automatic changeover)

¤ Wireless LAN (IEEE802.11b)

¤ Mini LAN (10BASE-T/ 100BASE-TX automatic changeover)

External (EXT) signal interface (14-pin)

Operation

Panel

Buttons LINE, FEED

FUNCTION, 4 navigation buttons (up/down/left/right), ENTER, CANCEL

Switch POWER ON/OFF

LCD Green LCD (with backlight), Vertical 32 dots x horizontal 128 dots, displaying up to five

icons at the top of the screen

LEDs POWER, ONLINE, STATUS, LABEL, RIBBON status indicators

Adjustment

Potentiometer VOLUME: buzzer loudness adjustment

PITCH: print-head pitch adjustment

OFFSET: tear off, peel, and cutter stop position adjustment

DARKNESS: print density adjustment

Sensor Paper sensor: reflection type, penetration type

Memory cartridge 16MB FLASH ROM, 4MB non-volatile user memory

Print Format Transmitted from host (computer) or recalled from print formats stored by user

on memory card (optional)

Stored

Font Types Standard X20 5 x 9 dots (alphanumeric, symbol, and kana)

X21 17 x 17 dots (alphanumeric, symbol, and kana)

X22 24 x 24 dots (alphanumeric, symbol, and kana)

X23 48 x 48 dots (alphanumeric, symbol, and kana)

X24 48 x 48 dots (alphanumeric, symbol, and kana)

Outline font (alphanumeric, symbol, and kana)

OCR-A GT408 15 x 22 dots (alphanumeric and symbol)

GT412 22 x 33 dots (alphanumeric and symbol)

GT424 44 x 66 dots (alphanumeric and symbol)

OCR-B GT408 20 x 24 dots (alphanumeric and symbol)

GT412 30 x 36 dots (alphanumeric and symbol)

GT424 60 x 72 dots (alphanumeric and symbol)

Truetype Fonts CG Times (alphanumeric and symbol)

CG Triumvirate (alphanumeric and symbol)

Kanji Fonts

(where applica-

ble)

16 x 16 dots (JIS level-1and -2 kanji sets. Selectable either Mincho or Gothic)

24 x 24 dots (JIS level-1and -2 kanji sets. Selectable either Mincho or Gothic)

22 x 22 dots (JIS level-1and -2 kanji sets. Selectable either Mincho or Gothic)

32 x 32 dots (JIS level-1and -2 kanji sets. Selectable either Mincho or Gothic)

40 x 40 dots (JIS level-1and -2 kanji sets. Selectable either Mincho or Gothic)

Kanji outline font

Section 1: Introduction

Page 1-6 GT Series Operator’s Manual

1.1 GENERAL SPECIFICATIONS (CONT’D)

Note:

All the GT printers use the same command codes. The only differences are the allowable values repre-

senting print positions on the label. Thesevalues are specified in “dots” and will vary depending upon the

resolution of the printer and the amount of memory available for imaging the label.

Specification/

Model Name GT408 GT412 GT424

Barcode One-

dimensional

code

• UPC-A/E, EAN8/13, JAN8/13

• NW-7

• INTERLEAVED 2 of 5 (ITF)

• INDUSTRIAL 2 of 5

• MATRIX 2 of 5

• CODE39, CODE93, CODE128

• UCC/EAN128

• Customer barcode

• RSS-14

Two-

dimensional

code

• QR code model 2, Micro QR (Ver 8.1)

• PDF417 (Ver. 2.4, including micro PDF)

• Veri code (Ver. 1.0)

• MAXI code (Ver. 3.0)

• Data matrix ECC200 (Ver. 2.0)

• Synthetic symbol (UPC-A/E, EAN8/13, JAN8/13, CODE39, CODE128 CC-A/B/C

supported with RSS-14)

Magnification Vertical 1 to 12 times

Horizontal 1 to 12 times (characters)

1 to 12 L (barcodes)

Rotation Characters: 0°, 90°, 180°, and 270°

Barcode: parallel 1, serial 1, parallel 2, serial 2

Barcode Ratio 1:2, 1:3, 2:5, arbitrary

User mode 1. Volume set value indication 2. Print speed 3. Print density

4. Print position correction 5. Zero slash changeover 6. Kanji code changeover

7. Kanji font setting 8. Proportional pitch setting

Automatic diagnostics Head check/ Head open/ Paper end/ Ribbon end/ Winding full/ Kanji ROM

check/ Test print

Noise emis-

sion Radiant noise VCCI Class B

Static with-

stand pressure IEC Level 3

AC line noise 1000 Vp-p or more (50 nS to 1 µS pulse)

Optional accessories • Peel unit (with mounting winder)

• Cutter unit

• Non-separate unit

• Simplified peel unit

• Internal winding unit

• External winding unit

• RFID unit

• Detection scanner unit

• EXT connector (external signal)

• Interface boards (serial RS-232C or Parallel IEEE1284)

• USB Interface board

• LAN (10BASE-T/100BASE-TX),

• Wireless LAN (IEEE802.11b),

• Mini LAN (10BASE-T/100BASE-TX)

Memory cartridge 24 MB

Section 2: Installation

GT Series Operator’s Manual Page 2-1

2

INSTALLATION

This section assists you in unpacking and installing the printer from the shipping container.

You will also be guided through a familiarization tour of the main parts and controls.

The following information is provided:

• Safety Precautions

• Unpacking and Parts Identification

• Loading the Carbon Ribbon

• Loading Labels and Tags

• Adjusting the Sensors

• Replacing the Print Head

• Turning the Printer ON/OFF

SECTION 2: INSTALLATION

Page 2-2 GT Series Operator’s Manual

SAFETY PRECAUTIONS

THE CAUTION SYMBOL

Whenever the triangular Caution logo appears in this manual, pay special attention to the warning(s) cited

below it. Failure to abide by the warnings may result in injury or damage to property.

PRINTER PLACEMENT TIPS

• Place the printer on a solid, stable,

horizontal surface that is not sub-

ject to strong vibrations from adja-

cent mechanical devices.

• Avoid shaky or slanting tables, or

platforms that are liable to collapse under a heavy

weight. If the printer is dropped or damaged, immedi-

ately turn off the power, pull out the power plug and

contact a service center. In this case, continued use

of the printer may cause a fire or electric shocks.

• Avoid installing the printer in direct sunlight, or in

dusty, very hot or slippery areas. Also avoid place-

ment in damp, unventilated or humid areas. If con-

densation forms, immediately turn off the power, and

do not use the printer until the condensation disap-

pears. Otherwise the moisture may cause electric

shocks.

• Avoid placing the printer near large high-current

equipment, as such equipment can cause spikes or

undervoltages in the power supply.

• Do not leave containers of

water or chemicals around the

printer. If any liquid is spilled

onto the printer, immediately

turn off the power, pull out the

power cable from the AC outlet, and contact a

sales outlet, dealer, or service center. In this

case, continued use of the printer may cause

fires or electric shocks.

• Do not move the printer with any paper loaded.

The stack of paper may fall off, causing trips

and accidents.

• When laying the printer down, be careful not to

catch your foot or fingers under it.

• When moving the printer, be sure to pull out the

power cable from the AC outlet, and check that

any other external interface cables have been

disconnected. Otherwise, the connected cables

may be damaged, or may cause trips and falls,

in addition to or a fire or electric shocks.

ELECTRICAL PRECAUTIONS

• Do not damage, break, or process the power cable.

Hanging heavy objects on it, heating or pulling it may

damage the power cable and cause fires or electric

shocks.

• When the power cable is damaged (cable conductors

are exposed or cut, etc.), contact a sales outlet,

dealer, or service center. In this case, continued use

of the printer may cause fires or electric shocks.

• Do not process, forcibly bend, twist, or pull the power

cable. Continued use of such a cable may cause

fires or electric shocks.

• If the printer emits any smoke or peculiar odors at

any time, turn it OFF and prevent further usage until

you have contacted a qualified service personnel.

• Do not use any other voltage except the specified

power voltage for the printer that matches your

domestic power supply. Otherwise, it may cause

fires or electric shocks.

• Do not operate the power switch or handle the

power cable with a wet hand.

• Do not insert or drop anything metallic or flam-

mable into the openings of the printer (the cable

outlet or mounting hole of the memory car-

tridge). Otherwise, immediately turn off the

power, pull out the power cable, and contact a

sales outlet, dealer, or service center. In this

case, continued use of the printer may cause

fires or electric shocks.

• To reduce electrical risks, be

sure to connect the printer to

ground before use. Also, try

not to share the printer’s AC

outlet with other electrical

equipment, especially those that draw high

amounts of current or cause electrical interfer-

ence.

SAFETY PRECAUTIONS

Please read the following information carefully before

installing and using the printer

Section 2: Installation

GT Series Operator’s Manual Page 2-3

This equipment is a piece of Class B information technology equipment based on the standards of the

Voluntary Control Council for Interference by Information Technology Equipment (VCCI). Although this

equipment is for use in home environment, if it is used close to a radio or television set, it may cause poor

reception. Handle it properly in accordance with the content from the instruction manual.

GENERAL PRECAUTIONS

• The supplied head cleaning liquid is flammable.

Never heat it or throw it into a fire. Keep it out of chil-

dren’s reach to avoid accidental consumption.

Should this occur, consult a doctor immediately.

• When opening/closing the cover, beware of getting

your fingers caught. Also, hold the opening/closing

cover well so that it will slip and fall.

• After printing, the print head remains hot. When

replacing paper or cleaning the printer immediately

after printing, be careful not to burn yourself.

• Touching even the edge of the printer head may

cause injuries. When replacing paper or cleaning the

printer, be careful not to hurt yourself.

• If the printer will not be used for extended periods of

time, disconnect the power cable for safety.

• When releasing and locking down the printer head,

be careful not to catch any other foreign in it except

label paper.

• Do not disassemble or perform modifications to

the printer, as this renders the product unsafe.

For maintenance, troubleshooting and repairs,

consult a sales outlet, dealer, or service center

for help, instead of attempting to perform this

yourself. Renewable annual service contracts

are available.

• When maintaining or cleaning the printer,

always disconnect the power cable for safety.

• Do not insert your hand or other objects into the

cutter.

• When loading roll paper, be careful not to catch

your fingers between the paper and the feed.

• Be careful not to hurt yourself when detaching

the back cover of the fanfold through the hole

and attaching it.

• The simplified cutter is structured as a blade.

Be careful not to cut yourself.

SECTION 2: INSTALLATION

Page 2-4 GT Series Operator’s Manual

2.1 UNPACKING

When unpacking the printer, take note of the following:

Note

The following illustrations are representative only. Your printer may not be packed exactly as shown, but

the unpacking steps are similar.

The box should stay right-side up.

Lift the printer out of the box carefully. If the printer was been stored in the

cold, allow it to reach room

temperature before turning it on.

Remove the plastic covering from the

printer. Set the printer on a solid, flat surface.

Inspect the shipping container and

printer for any sign of damage that

may have occurred during shipping.

Remove the accessory items from their

protective containers.

1

4

2

5

3

Section 2: Installation

GT Series Operator’s Manual Page 2-5

2.1.1 INCLUDED ACCESSORIES

After unpacking the printer, verify that the following materials are in the accessories or packaging:

Global Warranty

document Cleaning

Set

Information

leaflet* Head cleaning sheet

(wrapping sheet)

Power cable*

Two-pole adaptor*Accessory CD-ROMOperator’s Manual

Items marked with an asterisk may be different from what you see here, or may be excluded.

Please fill out the Global Warranty card and submit it

to us in order that we can provide fast and efficient

after-sales service. For malfunctions under normal

use, this product will be repaired free of charge

according to the warranty terms applicable for the

country of use.

Please do not discard the original packaging box and

cushioning material after installing the printer. They

may be needed in future, if the printer needs to be

shipped for repairs.

Important!

Sample paper*

SECTION 2: INSTALLATION

Page 2-6 GT Series Operator’s Manual

2.1.2 PARTS IDENTIFICATION

IDENTIFYING THE MAIN PRINTER PARTS

Lift this cover

upwards to access

ribbon and label

Pull down this panel

to access controls

Fixed front plate

Power switch

Pushing the I side turns the

printer ON. Pushing the O side

turns the printer OFF.

Operation Panel

Consists of an liquid crystal dis-

play screen, five status indica-

tors and the LINE and FEED

buttons.

Front Cover

(lifted up)

Ribbon take-up shaft

Head pressure

adjustment knob

Ribbon feeder

Label supply arm

Roll Guide lever

Roll Guide

Head lock lever

Head open lever

Front cover plate

Angled Front View

Front View

Section 2: Installation

GT Series Operator’s Manual Page 2-7

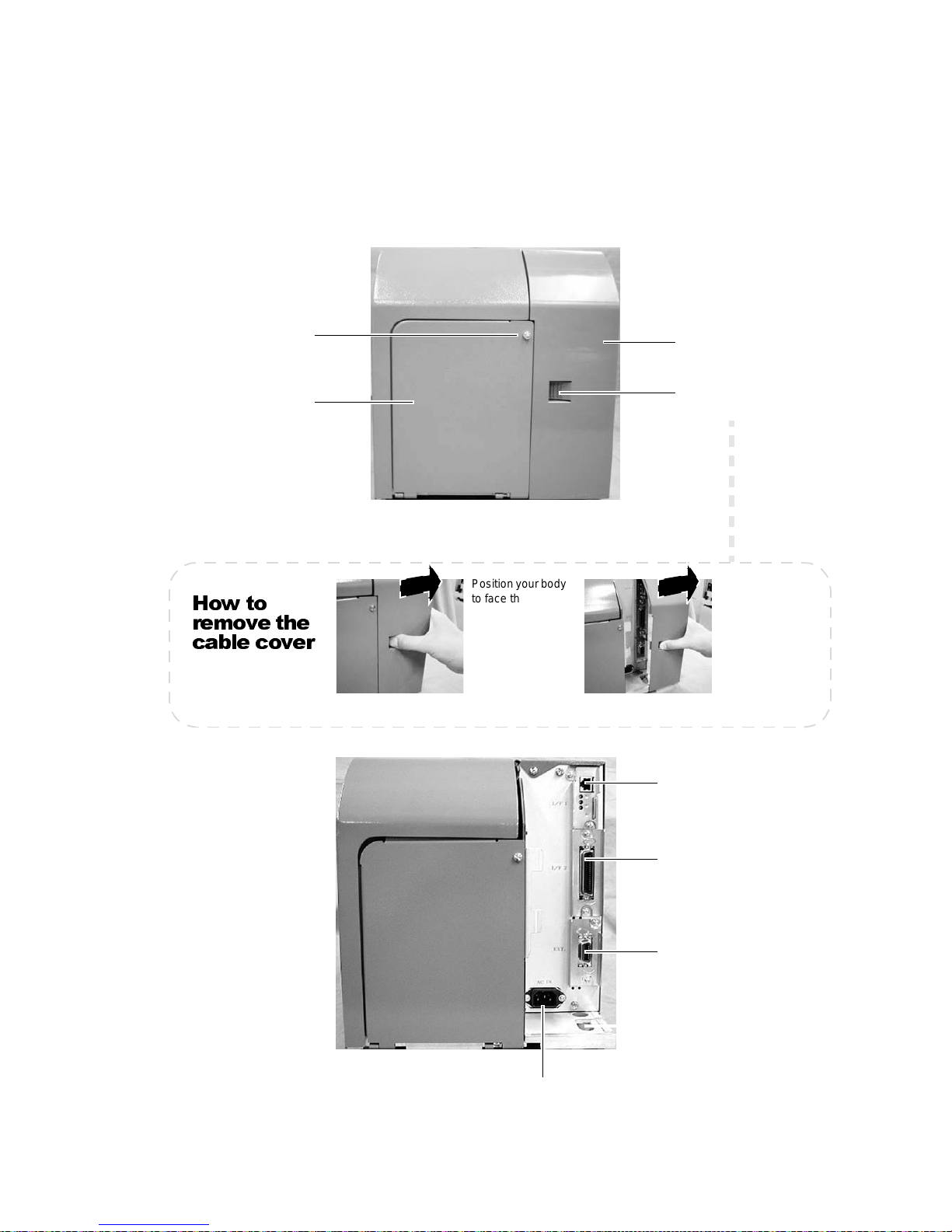

2.1.2 PARTS IDENTIFICATION (CONT’D)

IDENTIFYING THE MAIN PRINTER PARTS

Mini LAN interface

board (optional)

Available interfaces include

RS-232C, high speed RS-

232C, USB, IEEE 1284,

LAN and wireless LAN.

AC power connector

Power cable hook

Interface board

EXT connector

(optional)

Allows connection to external

devices

Provides a neat and safe way

to hang the power cable.

Cable cover

Release screw

Rear access cover

When using fanfold media,

remove the release screw

of the rear cover and lift up

the front cover. The hinged

rear cover will drop down-

wards to a vertical position.

Cable cover

release catch

How to

remove the

cable cover

Positionyourbody

to face the rear of

the printer. Press

down on the

release catch with

your thumb, and

slide the cable

cover to your right.

Position your

body to face the

rearof the printer.

Press down on

the release catch

with your thumb,

and slide the

cable cover to

your right.

Rear View

SECTION 2: INSTALLATION

Page 2-8 GT Series Operator’s Manual

IDENTIFYING THE MAIN PRINTER PARTS

Head lock lever

C

onnector for

o

ptional memory card

AA

B

C

Head release lever

Maintenance screw

Stopper screw

Label Guide

D

Head pressure knob

AA

B

C

D

Print head*

* Clean and maintain this part regularly

Platen roller*

(under the print head)

Stopper for

label damper

(push down-

wards to

release the

label damper)

Label Guide

handle

Label Guide

damper

Paper sensor

Fanfold cover

Ribbon take-up shaft

Ribbon feeder

Angled Front View

Head lock leve

r

Print head

This component generates

heat to the ribbon or media for

printing. Clean and maintain

this part regularly.

Platen roller

The rubber roller feeds or

retractsthemedia as needed.

Clean and maintain this

part regularly.

Label Guide

handle

Head release

lever

Side View

(Media assembly)

This manual suits for next models

5

Table of contents

Other SATO Printer manuals

SATO

SATO Argox X-1000VL User manual

SATO

SATO Argox D4 Series User manual

SATO

SATO M-5900RV User manual

SATO

SATO CT 400 User manual

SATO

SATO MN-4203 User manual

SATO

SATO SX4M User manual

SATO

SATO Argox iX4 Series User manual

SATO

SATO LC400e Series Owner's manual

SATO

SATO CL408e User manual

SATO

SATO M10e Series User manual