SATO D508 User manual

PN: 9001178

D508/D512

PRINTER

SERVICE MANUAL

PN: 9001178

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosale[email protected]

techsupport@satoamerica.com

www.satoamerica.com

PN: 9001178

Table of Contents

Overview

Introduction ........................................................................................................................................... 1-3

Unpacking ............................................................................................................................................. 1-4

Printer Part Names ............................................................................................................................... 1-5

Setting Up The Printer .......................................................................................................................... 1-6

Loading Media ...................................................................................................................................... 1-7

Label Sensing ....................................................................................................................................... 1-9

3.1 Operating Panel ............................................................................................................................ 1-10

Configuration: The Rear Panel ........................................................................................................... 1-11

The Configuration Panel ..................................................................................................................... 1-12

Switch 4: Unused ................................................................................................................................ 1-13

Switch 5: Head Check ........................................................................................................................ 1-13

Switch 6: VR1 Potentiometer Adjustment mode ................................................................................. 1-13

Offsets ................................................................................................................................................ 1-15

Potentiometer Adjustments ................................................................................................................. 1-16

Data Dump Diagnostic Label .............................................................................................................. 1-18

Printing Test Labels ............................................................................................................................ 1-19

Printing Factory/Service Test Prints ................................................................................................... 1-20

Basic and Interface Specifications

1.1 Basic Printer Specifications .......................................................................................................... 2-2

1.1 General Specifications (cont’d) ...................................................................................................... 2-3

Interface types ...................................................................................................................................... 2-6

The Receive Buffer ............................................................................................................................... 2-7

IEEE1284 Parallel Interface .................................................................................................................. 2-9

RS-232C Interface .............................................................................................................................. 2-10

RS-232C Interface Signals ................................................................................................................. 2-11

Universal Serial Bus Interface ............................................................................................................ 2-12

Local Area Network Interface ............................................................................................................. 2-13

Wireless 802.11 LAN Interface ........................................................................................................... 2-13

Troubleshooting

Interface Troubleshooting ..................................................................................................................... 3-5

Troubleshooting Flowcharts .................................................................................................................. 3-7

Problem: Printer Does Not Power Up ................................................................................................... 3-7

Problem: Label Does Not Feed Outward In A Straight Path ................................................................. 3-8

Problem: Printer Does Not Print ........................................................................................................... 3-8

Problem: Printer Does Not Print ........................................................................................................... 3-9

Problem: Printer Does Not Feed Labels ............................................................................................. 3-10

Problem: Printer Does Not Stop At The Correct Position ................................................................... 3-11

Problem: Wireless LAN Printer Is Not Printing ................................................................................... 3-11

Problem: Printing Is Too Dark ............................................................................................................. 3-12

Problem: Printing is Too Light On One Side ....................................................................................... 3-12

Problem: Print Start Position Is Incorrect Vertically ............................................................................ 3-13

Problem: Print Start Position Is Incorrect Horizontally ........................................................................3-14

Problem: White Lines Appear In Printed Labels ................................................................................3-14

Problem: Labels are Not Being Dispensed Properly By The Optional Dispenser Unit ...................... 3-15

Problem: The Cutter Is Not Working ................................................................................................... 3-16

Problem: The Cutter Is Not Working ................................................................................................... 3-16

Test Print Troubleshooting .................................................................................................................. 3-17

Test Labels ......................................................................................................................................... 3-17

Data Dump Diagnostic Label .............................................................................................................. 3-19

Printing Factory/Service Test Labels .................................................................................................. 3-20

Replacement Procedures

Print Head Replacement ....................................................................................................................... 4-2

Platen Roller Replacement ................................................................................................................... 4-3

Accessing the Main Board .................................................................................................................... 4-4

Fuse Replacement ................................................................................................................................ 4-5

Main Circuit Board Replacement .......................................................................................................... 4-6

Panel Board Replacement .................................................................................................................... 4-7

Relay Board (Label Sensor Board) Replacement ................................................................................. 4-8

Label Sensor Replacement ................................................................................................................ 4-10

Cover Sensor Replacement ................................................................................................................ 4-12

Drive Motor Replacement ................................................................................................................... 4-14

Drive Gear Replacement .................................................................................................................... 4-16

Cutter Assembly ................................................................................................................................. 4-18

Checks/Adjustment Procedures

Top of Forms Offset .............................................................................................................................. 5-2

Factory Clear ........................................................................................................................................ 5-3

Print Darkness ...................................................................................................................................... 5-4

Printer Counter Clear ............................................................................................................................ 5-6

Cutter Counter Clear (If Cutter Is Installed) .......................................................................................... 5-6

Test Print Counter Clear ....................................................................................................................... 5-7

Cut Position (If Cutter Is Installed) ........................................................................................................ 5-7

Eye Mark / Paper End Sensor Sensitivity ............................................................................................. 5-8

Paper End Sensor Sensitivity (Alternate) ............................................................................................. 5-8

Gap Sensor Sensitivity ......................................................................................................................... 5-9

Gap Sensor Sensitivity (Alternate) ........................................................................................................ 5-9

Power Supply Checks ......................................................................................................................... 5-10

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-1

OVERVIEW

Page 1-2 SATO D508/D512 Service Manual

OVERVIEW

Thank you for your investment in this SATO printer product.

This Service Manual contains information about the specifications, replacement procedures,

checking/calibration procedures, and troubleshooting of common problems associate with the

D508/D512. A total of four topics are covered herein, and they are organized as follows:

Section 1: Overview

Section 2: Basic and Interface Specifications

Section 3: Troubleshooting

Section 4: Replacement Procedures

Section 5: Checks and Adjustment Procedures

The Overview section provides a description of the printer, information on how to access the

main board, how to unpack the printer, how to identify the printer parts, how to set up the printer,

how to load media, information on label sensing and configuration, adjustments, and test labels.

The Basic and Interface Specifications section serves as a guide to personnel who need to

understand the communication protocols needed to control the printer using third party software,

and for troubleshooting interface problems.

The Troubleshooting section aids in the process of diagnosing and correcting common prob-

lems. After troubleshooting, the service personnel can then determine whether any repairs, parts

replacements and/or adjustments are necessary,

The Replacement Procedures section covers the main components of the product, and how the

service personnel can dismantle and reassemble the parts in order to maintain, clean, repair or

replace them.

Finally, the Checks and Adjustment Procedures are needed after certain maintenance or

repair work involving certain precision components.

It is recommended that you become familiar with each section before attempting to service the

product. Refer to the Table Of Contents at the front of this manual to search for the relevant

information needed. All page numbers in this manual consist of a section number followed by the

page number within the stated section.

Note:

All information herein was correct and current at the time of publication. The contents of this doc-

ument are subject to revision and change without prior notification to users. To obtain the most

current version of this document, refer to the SATO website at www.SATOAmerica.com.

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-3

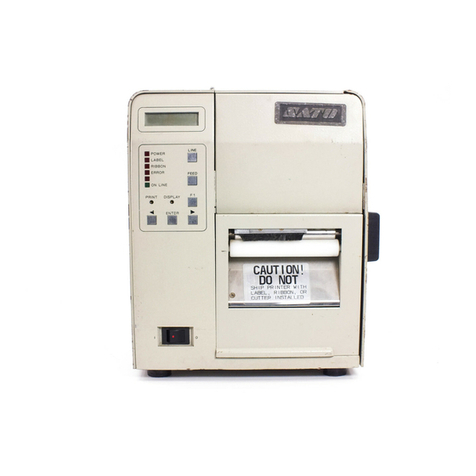

INTRODUCTION

The SATO D508/D512 Printer Service Manual provides information for installing and maintaining

D508/D512 Direct Thermal printers. Step-by-step maintenance instructions are included in this

manual with typical problems and solutions. It is recommended that you become familiar with

each section in this manual before installing and maintaining the printer.

The major difference in the D508 and the D512 printers is the resolution of the print head. The

D508 with its 203 dpi head provides an economical labeling solution for most applications. It can

print labels up to four inches wide. The D512's higher 305 dpi resolution provides greater detail

for graphics and small point size text.

The D5 Series printers use a subset of the standard SATO Command Language. The D508 and

D512 share the same command set, the only differences are the allowable values representing

the print positions on the label. These values are specified in "dots" and will vary depending upon

the resolution of the printer and the amount of memory available for imaging the label. The allow-

able range for each printer is specified in a table for those command codes. In addition, users

can choose an interface—such as parallel (IEEE1284), serial (RS-232C), Ethernet (10/100-

BaseT), USB 1.1and Wireless LAN IEEE 802.11b.

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-4

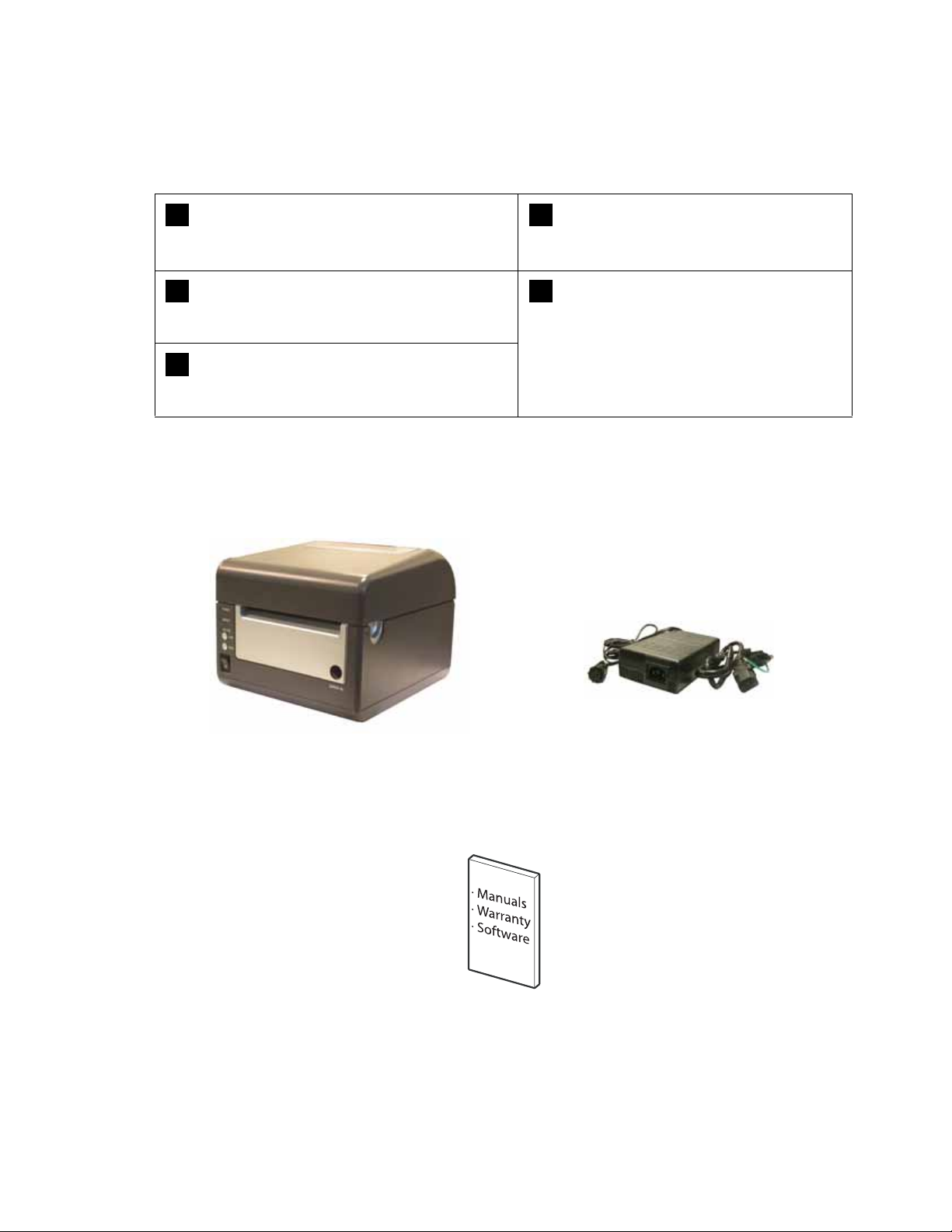

UNPACKING

When unpacking the printer, take note of the following:

Note:

The following parts shown here are representative only. Due to regional requirements and our policy of

continual improvement, your printer may not be packed with the exact parts as shown here, but the

unpacking steps are similar.

The box should stay right-side up.

Lift the printer out of the box carefully.

If the printer has been stored in the

cold, allow it to reach room

temperature before turning it on.

Remove the plastic covering from the

printer.

Set the printer on a solid, flat surface.

Inspect the shipping container and

printer for any sign of damage that

may have occurred during shipping.

Remove the accessory items from their

protective containers.

1

4

2

5

3

Printer AC adaptor and cable

User documentation and software

package (where applicable)

Page 1-5 SATO D508/D512 Service Manual

PRINTER PART NAMES

Clear window and

fanfold-label Loading

Top Cover

Label Outlet

Front cover

(allows access to optional cutter unit, DIP switches

and potentiometers)

LINE/FEED/

Power

buttons and

LEDs

7-segment

Error Status LED

Release latch for Top Cover

Mini

Screwdriver

Label Holders

Thermal Print

Head assembly

Label Holder Release Knob

Platen Assembly

Label Sensor

Optional Cutter

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-6

SETTING UP THE PRINTER

Consider the following when setting up the printer:

Locate a solid flat surface with adequate room to set the printer. Make sure the AC

adaptor can be located so that the AC power cable can be attached to the printer and

an AC power outlet. The location should be near the host or computer terminal. The

maximum distance recommended is:

- 10 feet for a Parallel interface cable. Make sure it meets IEEE1284 specifications

- 18 feet for the optional Serial RS232 Interface

- 10 feet for the optional USB interface without hub

- the optional 10baseT Ethernet Interface depends upon the LAN cabling

- Up to 100m for the Wireless LAN, depending on structural conditions

Follow these steps to set up your printer:

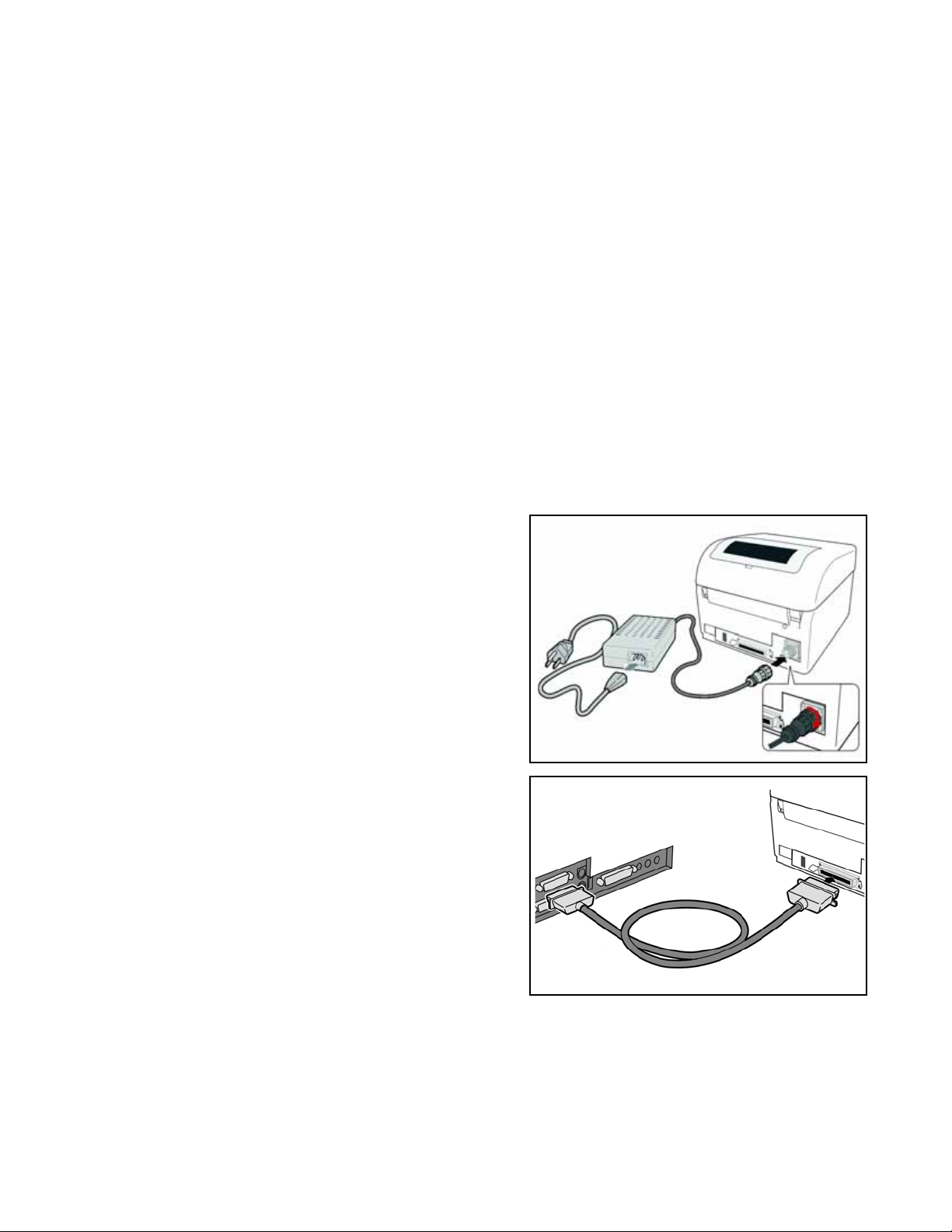

1. Make sure the power switch on the Operator

Panel is in the OFF (0) position and place the

AC adaptor in a safe and secure location.

2. Connect the Input Power connector to the

printer. This connector is buttoned and must

be turned approximately 3/4 turn clockwise to

secure it to the printer.

3. Connect the AC Power Cable to an AC Outlet

supply of an appropriate voltage.

4. Connect the interface cable to the host system.

If you are using the Parallel Port connection, a

parallel IEEE1284 interface cable must be

used to realize the high data transfer rate of

the printer's parallel port. If another interface is

installed, the appropriate cable should be

used.

5. Load the label media following the instructions

in this section.

6. Configure the printer for label width and operating mode using the instructions in this section.

7. Press the printer power button to the ON (I) position.

8. Print a test label to verify the printer is set up and operating correctly.

Page 1-7 SATO D508/D512 Service Manual

LOADING MEDIA

The SATO D508/D512 printer can print to direct thermal die-cut labels, tags or continuous media.

The media supply can be either in Roll or Fanfold format.

Roll Media

Roll media should be between 0.98" (25 mm) and 4.3" (110 mm) in width and wound face-out on

a core with a minimum internal diameter of 1.6" (40 mm).

1. Make sure the printer is turned OFF.

2. Open the Top Cover by pressing on cover

release points located on the right-hand

side of the printer. This releases the Top

Cover and allows it to swing upward on the

rear mounted hinge points.

3. With the Top Cover in the upright position,

press the Paper Guide Release while

adjusting the Paper Guides until they allow

a media roll to fit between them. A millime-

ter scale is molded into the case to provide

a guide when making the adjustment. The

Paper Guides are center justified and inter-

act with each other so that each moves an

equal distance.

4. Make sure the Roll Holders are in the

released position. If they are not, lift up on

each one and they will snap to the open

position.

5. Unwind approximately 12" of label material

from the roll. The labels should be wound

face-out (printing side to the outside of the

roll). Drop the roll in-between the Paper

Guides so that the labels come off the top

of the roll. The Paper Guides will automati-

cally position the Roll Holders to suspend

the roll.

Cover/Print Head

Release Latch

Roll Holders

Paper

Sensor

Millimeter

scale

Paper Guide

Release

Label path

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-8

6. Route the label material through the Paper

Sensor Assembly and over the Platen. Note

that the Sensor is part of the left Label Roll

Guide so that the Paper Sensor is always

positioned in the same location relative to

the left edge of the label.

7. Close the Top Cover.

8. Press the LINE button so that the printer is

in the OFF LINE mode and then press the

FEED button. The label should advance to

the next index (label gap) position.

Fanfold media

1. Place the fanfold media behind the printer

with the printing surface up.

2. Open the Top Cover by pressing on the cover

release latch located on the right-hand side

of the printer. This releases the cover and

allows it to swing upward on the rear

mounted hinge points.

3. Carefully pull up the Fanfold-label Loading

Slot from the back of the Top Cover.

4. With the Top Cover in the upright position,

press the Paper Guide Release while adjust-

ing the Paper Guides until they allow a media

to fit between them. A millimeter scale is

molded into the case to provide a guide when

making the adjustment. The Paper Guides

are center-justified and interact with each

other so that each moves an equal distance

apart from each other.

5. Route the label material through the Sensor

Assembly and over the Platen.

Paper Sensor Paper Guide

Platen

Pull up

the

loading

slot

Pull

open

the Top

Cover

Load

the

fanfold

paper

Page 1-9 SATO D508/D512 Service Manual

6. Close the Top Cover.

7. After loading the label media, it is

recommended that you run a Test

Print to make sure the labels are

correctly loaded and printed.

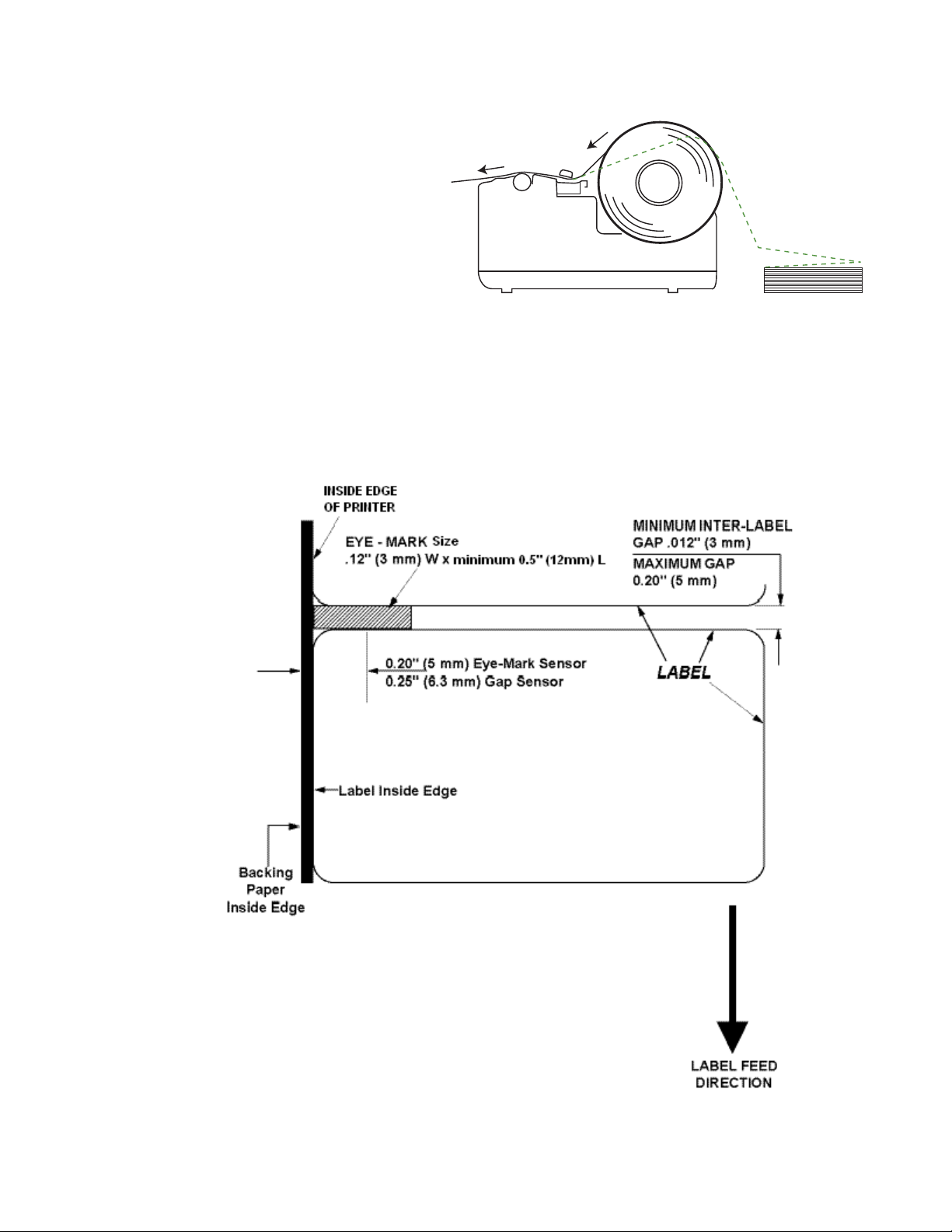

LABEL SENSING

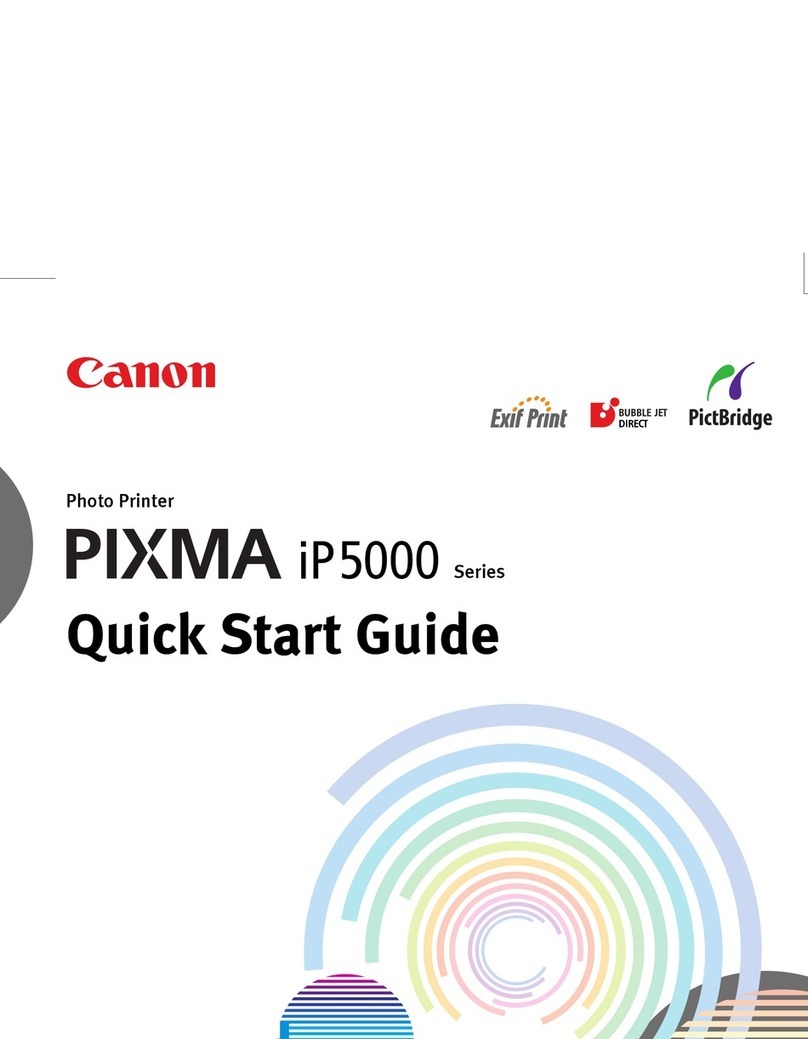

The SATO D508/D512 uses label Gap (see-through) or Eye-Mark (reflective) sensing. The

Sensor Assembly is located on the left edge of the media and is automatically positioned by the

Paper Guides.

Fanfold-label path

Roll-label path

Overview of the fanfold-paper loading path

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-10

CONFIGURATION

Before using the printer, it is best to read this manual thoroughly first. Otherwise, you may disturb

default settings around which the instructional procedures in this manual are based upon.

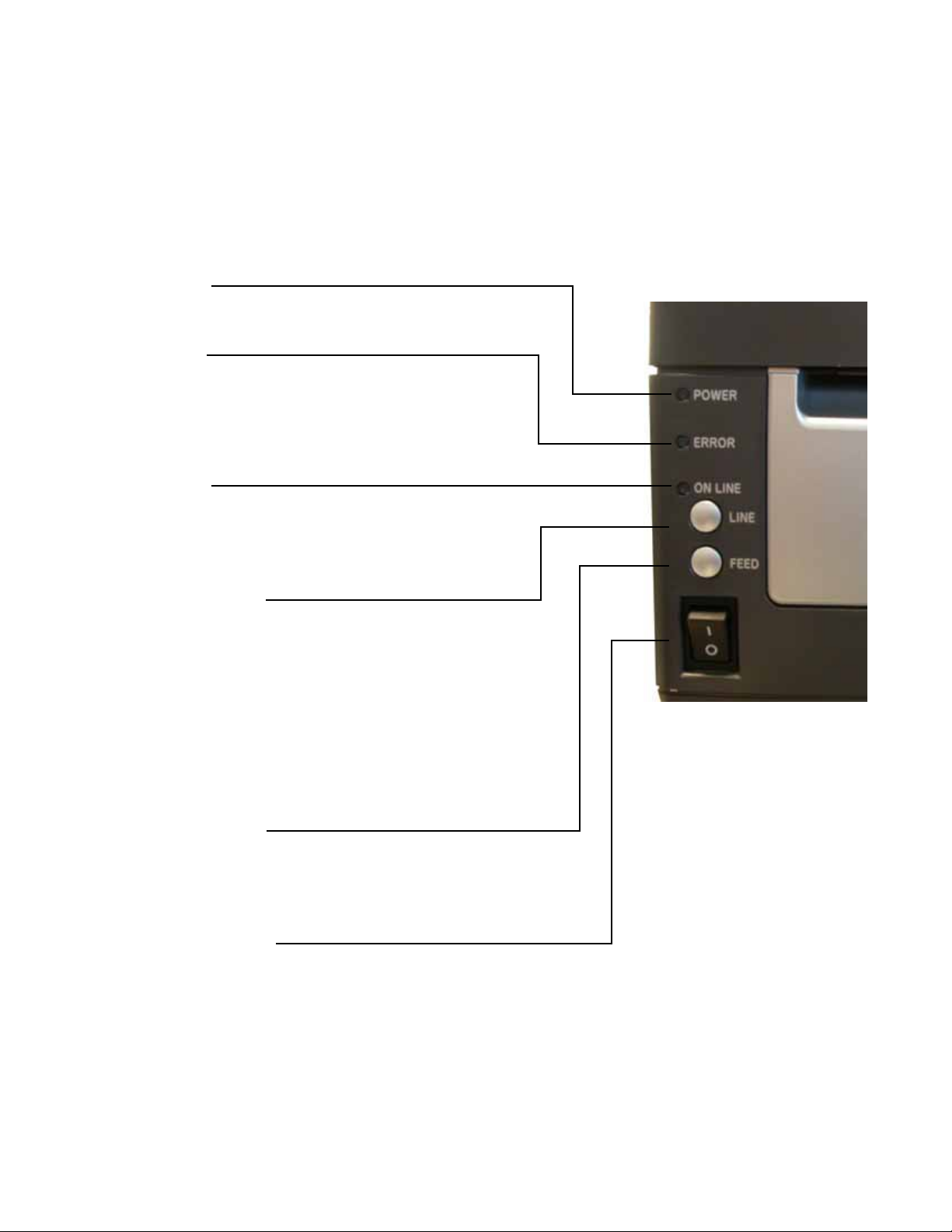

3.1 OPERATING PANEL

The Operator Panel consists of three LED indicators and three switches.

POWER

The green LED lights up when the printer is ON.

ERROR

The red LED lights up when there is a system fault

such as an unlatched print head.

ON LINE

The green LED lights up when the printer is ON LINE

and ready to receive data. The ON LINE button

takes the printer ONLINE or OFFLINE.

LINE Button

If the ONLINE LED is lit, pressing it will take the printer

OFFLINE. Pressing the button again then takes the printer

back ONLINE. When ONLINE, the printer is ready to

receive data from the host. When OFFLINE, the printer

will not print or accept data from the host. While the

printer is printing, press this button to suspend the

printing. To resume printing, press this button again.

FEED BUTTON

Press this button to eject one label in OFFLINE mode.

Hold this button down while power is applied, to print a printer

status label.

POWER SWITCH

A two position switch for turning the printer ON (I) or OFF (0).

Page 1-11 SATO D508/D512 Service Manual

CONFIGURATION: THE REAR PANEL

All of the printer cable connectors are located on the Rear Panel, as follows.

Fanfold-label Loading Slot

Remove this panel to route fanfold paper into the printer

Power

Connector

for DC power

input from the

supplied AC

Adapter

Interface

Slot

(IEEE1284

Parallel

Interface

Connector

shown)

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-12

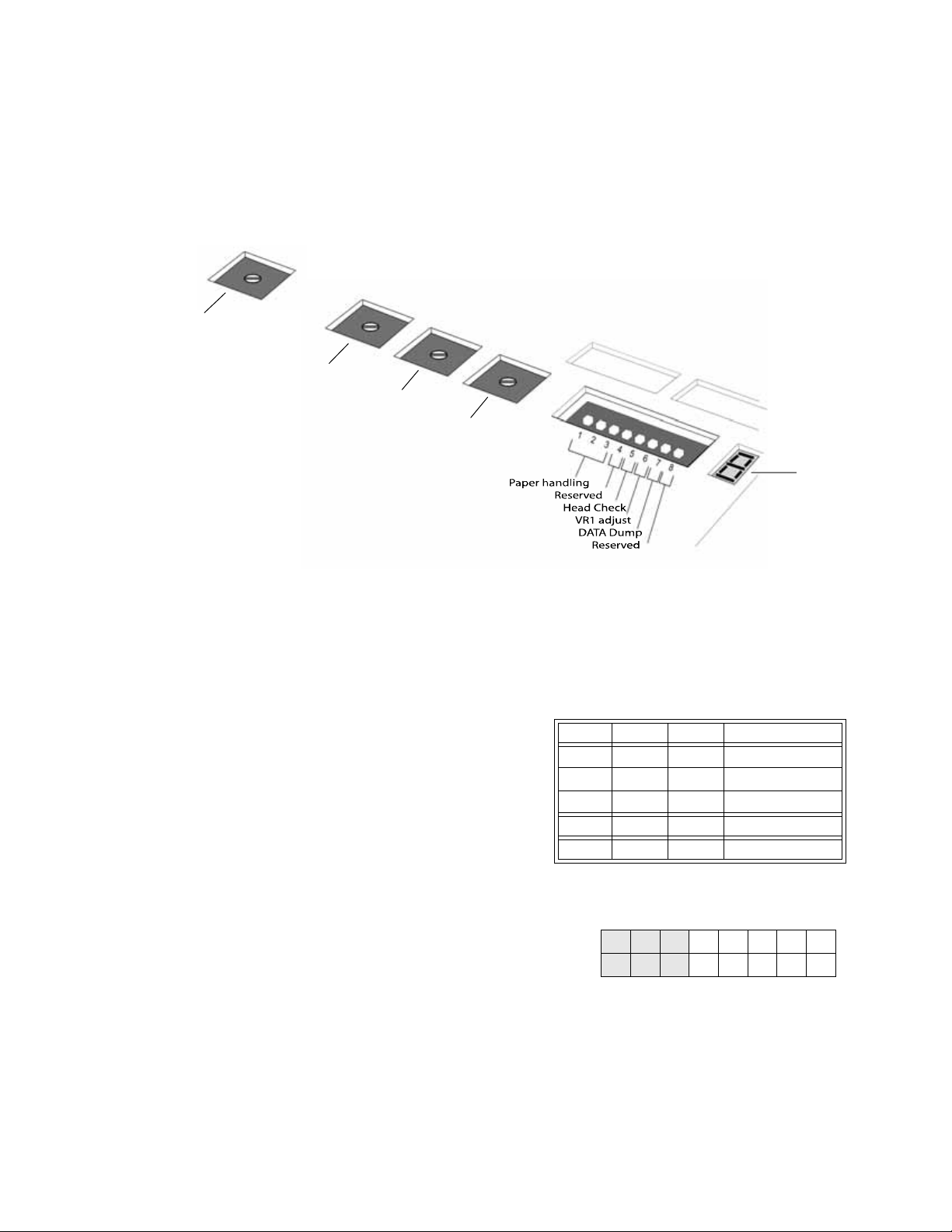

THE CONFIGURATION PANEL

The Configuration Panel is accessible when you lift up the top cover.

The panel consists of an eight-position DIP switch, four adjustment potentiometers and a seven-

segment LED Error Status display. Receptacles for connecting the optional Cutter (factory

installed) are also located on this panel.

DIP SWITCH SETTINGS

This is an eight-position switch used for setting the operating conditions of the printer. Switches 1

to 3 act as control for both paper handling and the loading of programs or fonts into the printer.

Switches 1–3: Paper Handling settings

These three switches select the method used for

controlling paper handling:

Continuous mode - (default mode) Does not

use the sensor for paper indexing. The paper

movement will stop after all the label data has

been printed.

Tear Off mode - Paper is fed out to the cut/tear

off position after printing is complete. Before the

next label is printed, the paper is pulled back in

to the first print line position.

Cutter mode - Enables the Cutter option if

installed.

Error

Status

LED

DIP switch for

Configuration

VR4

Label Pitch

Offset

VR2

EYE MARK

VR3

GAP

VR1

Offset or

Darkness

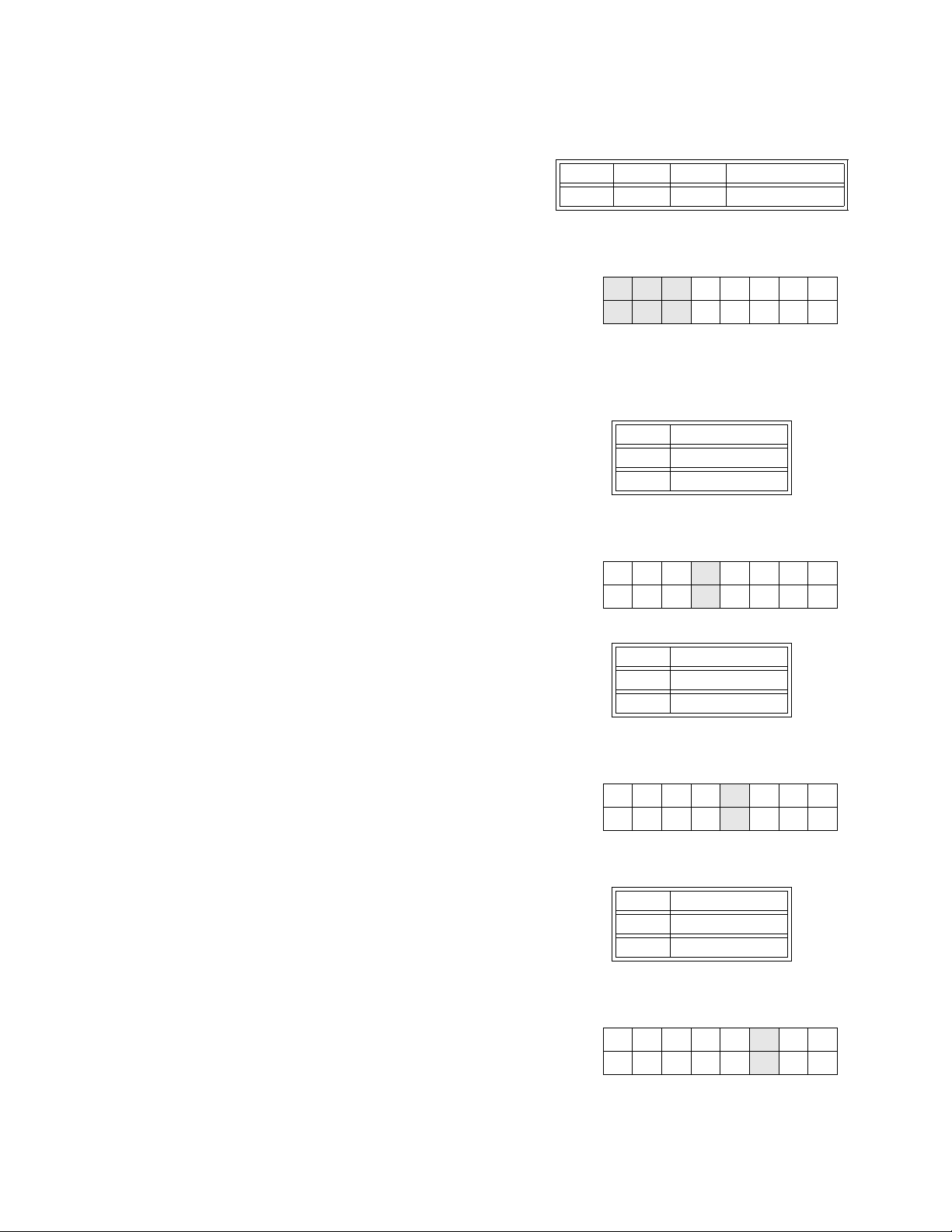

DSW1 DSW2 DSW3 Mode

Off Off Off Continuous

On Off Off Tear Off

Off On Off Cutter

On Off On Reserved

Off On On Load Font

Configuration Switch

ON

OFF

12345678

Page 1-13 SATO D508/D512 Service Manual

DIP SWITCH SETTINGS (CONT’D)

Switches 1–3: Font/Graphic loading settings

Enables the loading of fonts and/or graphics into

printer memory for faster retrieval.

Switch 4: Unused

This switch is reserved for future use.

Switch 5: Head Check

Enables or Disables the printer function that checks

the print head automatically.

Switch 6: VR1 Potentiometer Adjustment mode

Selects the function adjusted by VR1. When placed

in the OFF position, VR1 will adjust the media tear-

off / cut (backfeed distance) offset value over a

range of +/- 3.75 mm. When placed in the ON

position, VR1 will adjust the print darkness range.

DSW1 DSW2 DSW3 Mode

Off On On Load Font

Configuration Switch

ON

OFF

12345678

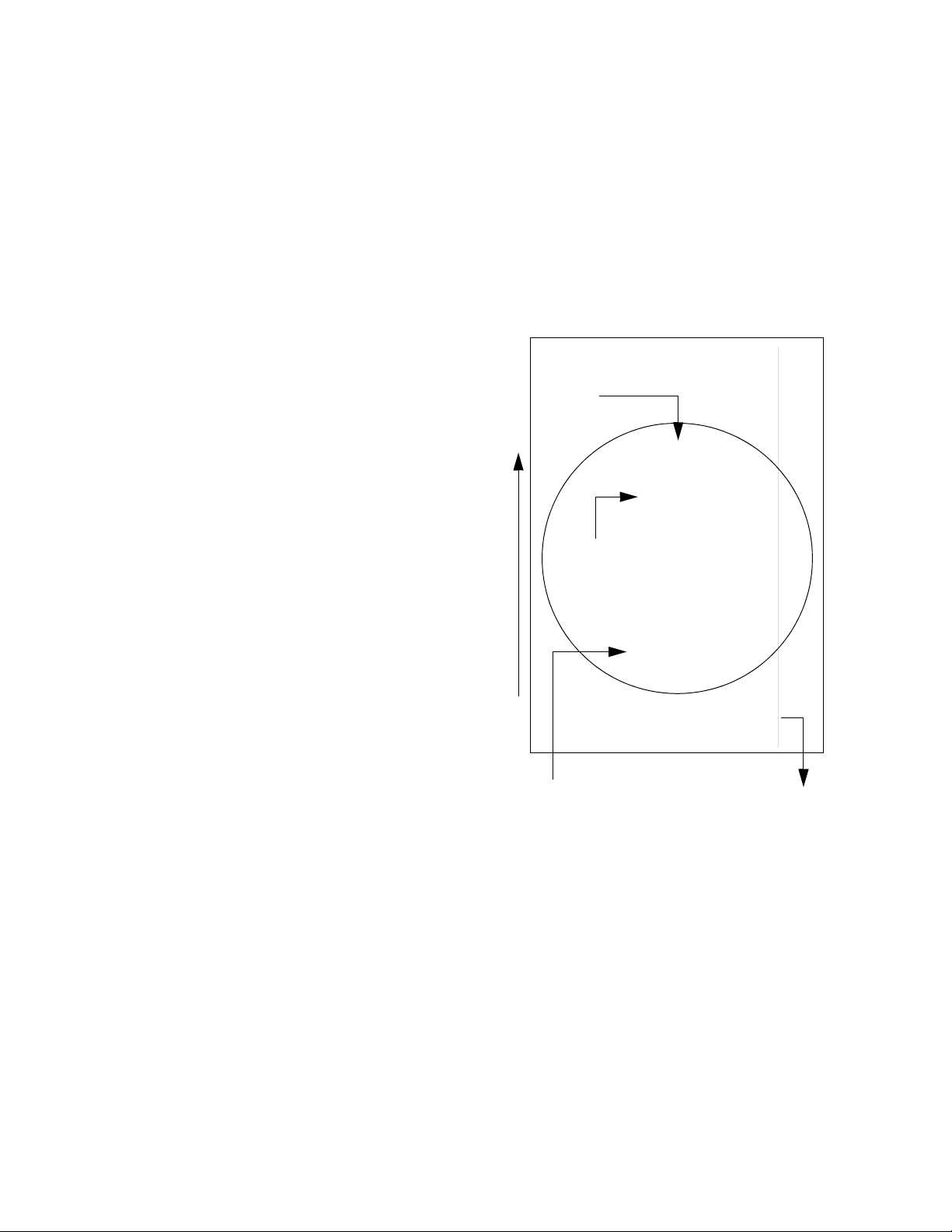

DSW4 Mode

Off DT

On Reserved

Configuration Switch

ON

OFF

12345678

DSW5 Mode

Off Disabled

On Enabled

Configuration Switch

ON

OFF

12345678

DSW6 Mode

Off Media Tear-Off

On Print Darkness

Configuration Switch

ON

OFF

12345678

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-14

DIP SWITCH SETTINGS (CONT’D)

Switch 7: DATA Dump

When ON, the printer will print out the hex value for

each character received. When OFF, the printer will

accept and process the data stream in a normal

fashion.

Switch 8: Unused

This switch is reserved for future use.

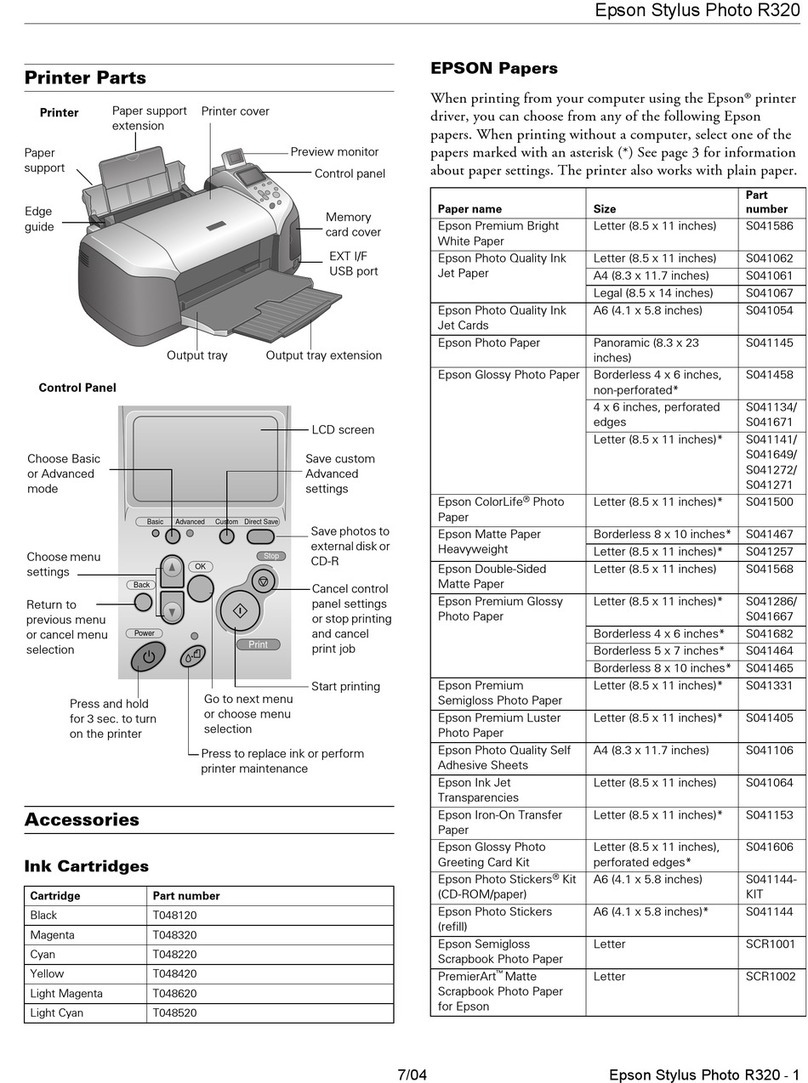

DSW7 Mode

Off Disabled

On Enabled

Configuration Switch

ON

OFF

12345678

DSW8 Mode

--

--

Configuration Switch

ON

OFF

12345678

Page 1-15 SATO D508/D512 Service Manual

OFFSETS

There are two offset settings stored in the printer; one for the Cut mode and one for the Tear-Off

mode.

These two offsets can be set independently and will remain in the printer until a new command is

received changing the setting or until power is turned off.

The default settings can be determined by printing a User Test Label.

The following should be used as starting points for establishing the three Offset values:

Mode Length of Offset (mm) Length of Offset (in) Print head resolution

CUTTER 17.9 0.70 143/215

TEAR-OFF 29.2 1.15 234/350

Unit 1: Overview

SATO D508/D512 Service Manual Page 1-16

POTENTIOMETER ADJUSTMENTS

PITCH OFFSET

This can be done using the VR4 potentiometer on the Configuration Panel. This potentiometer is

set at the factory so that it has a range of +/-3.75 mm. The midpoint setting should have no effect

on the label pitch. Turning the potentiometer all the way clockwise should move the print position

3.75 mm upwards towards the leading edge of the label. Turning the it all the way

counterclockwise should move the print position down 3.75mm away from the leading edge of

the label.

1. Place DSW6 on the Configuration Switch in

the OFF position.

2. Turn the power OFF.

3. While pressing the FEED button on the

Operator Panel, turn the power ON.

4. When you hear one beep from the printer,

release the FEED button.

5. Press the LINE button to begin printing

large Test Labels (press the FEED button

if you are using labels smaller than 4.1"

(104 mm) in width).

6. Adjust potentiometer VR4 until the first

print position is at the desired location on

the label.

7. Press the FEED button to stop printing.

Note:

Adjusting the Label Pitch with VR4 will

affect the stop position of the label and the

cut/tear-off positions.

ABCDEFG

ABCDEFG

ABCDEFG

Leading Edge of

Label as detected

by the sensor

Moved with

Positive (+) Offset

to print on trailing

edge of label

Must be moved with Minus (-)

Offset to print on leading edge of

label

Original First Line

Print Position

label movement direction

Other manuals for D508

2

This manual suits for next models

1

Table of contents

Other SATO Printer manuals

Popular Printer manuals by other brands

Evolis

Evolis Elypso user guide

Lexmark

Lexmark 522n - C Color Laser Printer Service manual

Kyocera

Kyocera FS-9530DN specification

Epson

Epson R320 - Stylus Photo Color Inkjet Printer Product information

Roland

Roland SOLJET Pro III XC-540 Service notes

Canon

Canon iP5000 - PIXMA Color Inkjet Printer quick start guide

Brother

Brother QL-570VM - B/W Direct Thermal Printer user guide

Canon

Canon Pixma TS3400 Series Getting started

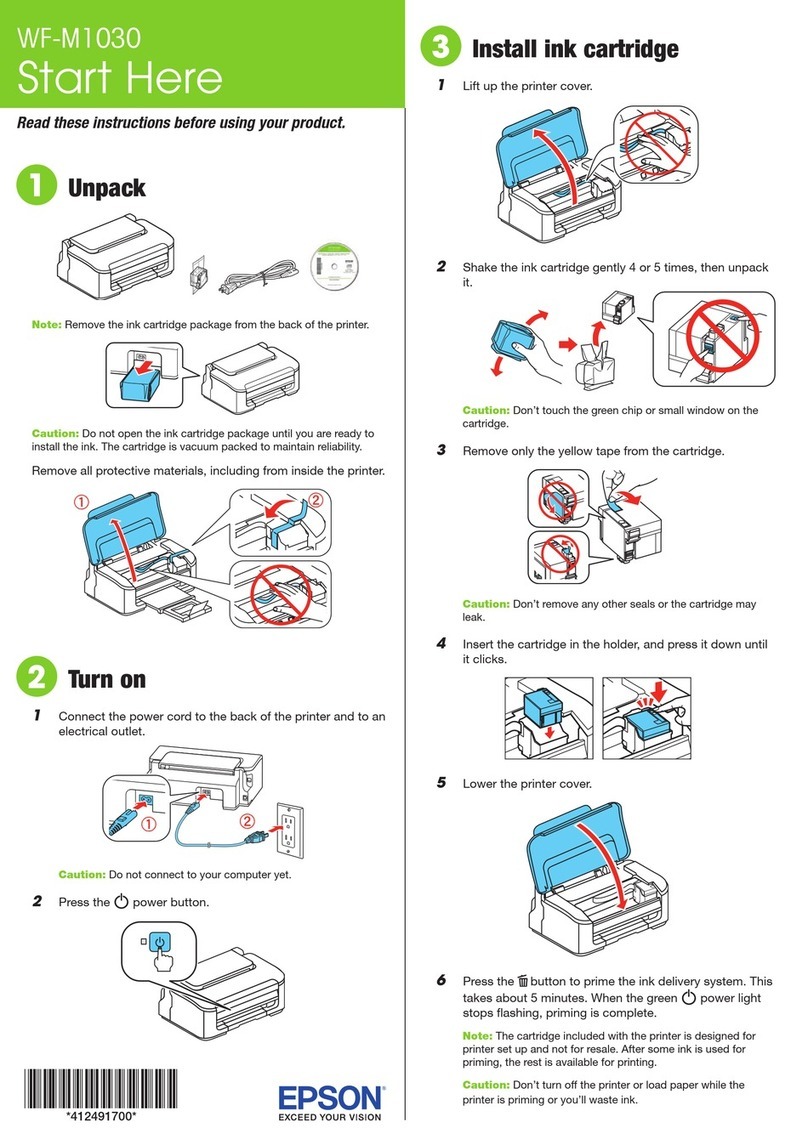

Epson

Epson WorkForce WF-M1030 Start here

Craind Impianti

Craind Impianti FT190S user manual

AMT Datasouth

AMT Datasouth Documax 5380 quick start guide

Toshiba

Toshiba TEC B-850 Series Key Operation Specification