Thank you for purchasing the mobile digital Leeb impact hardness tester from

SAUTER. We hope that you will be very satisfied with the high quality of this device

and its extensive functionality. For any questions, wishes and suggestions we are at

your disposal.

Table of contents:

1Before commissioning.................................................................................. 3

2Introduction.................................................................................................... 3

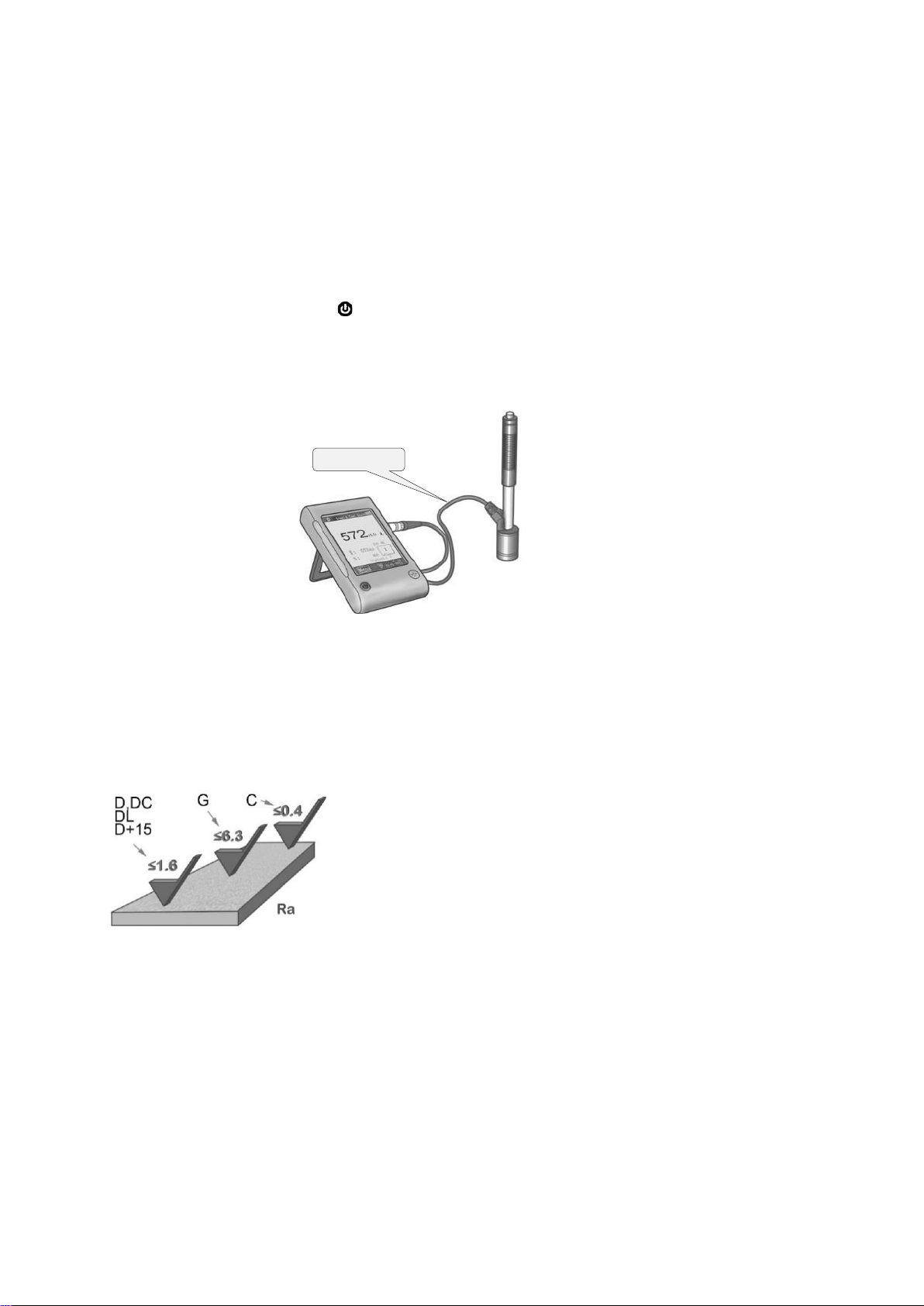

2.1 Measuring principle.................................................................................................................. 3

2.2 Structure.................................................................................................................................... 4

2.3 Technical data........................................................................................................................... 5

2.4 Area of application ................................................................................................................... 5

3Test procedure............................................................................................... 6

3.1 Preparation of the device ........................................................................................................ 6

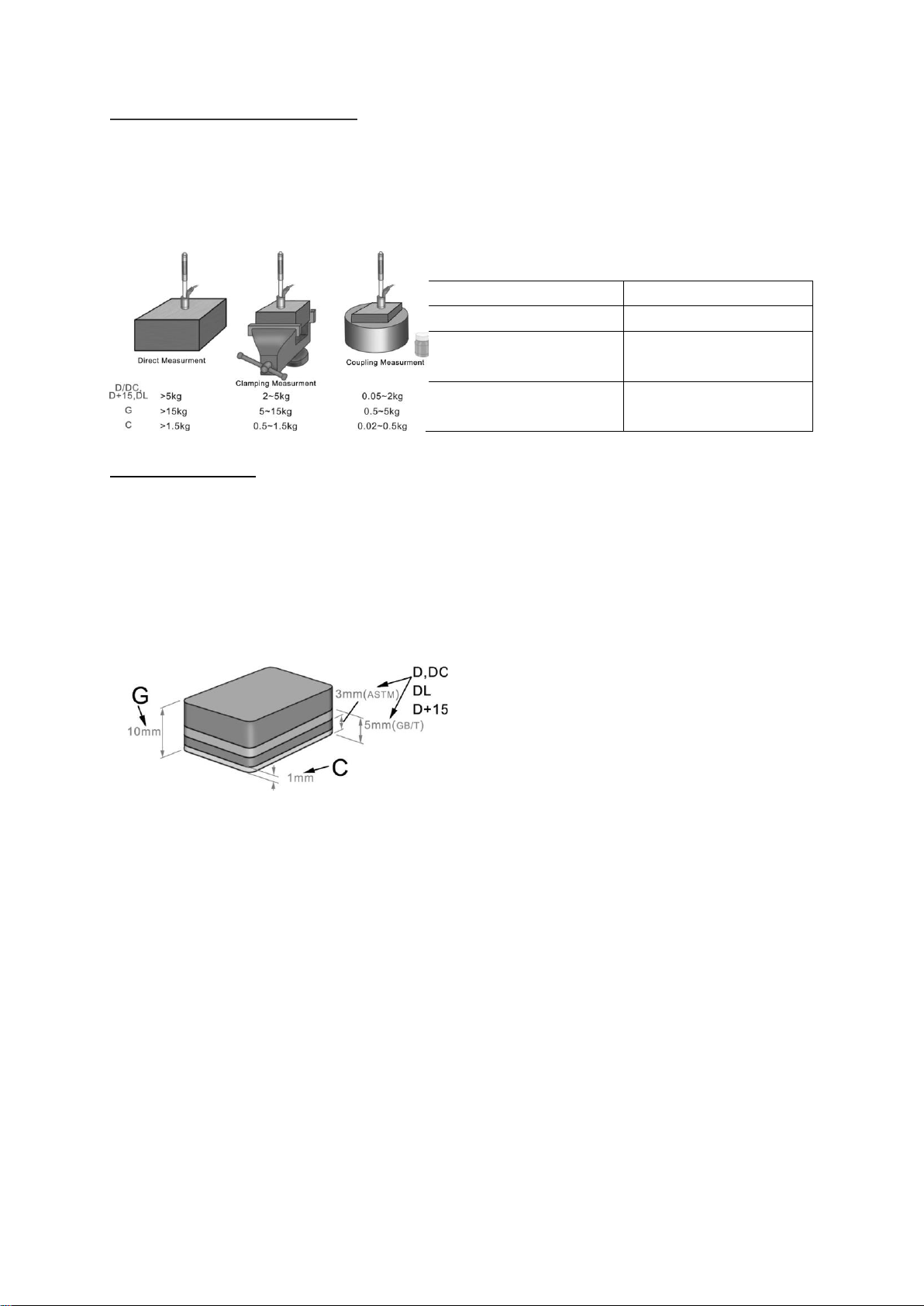

3.2 Preparation of the sample ....................................................................................................... 6

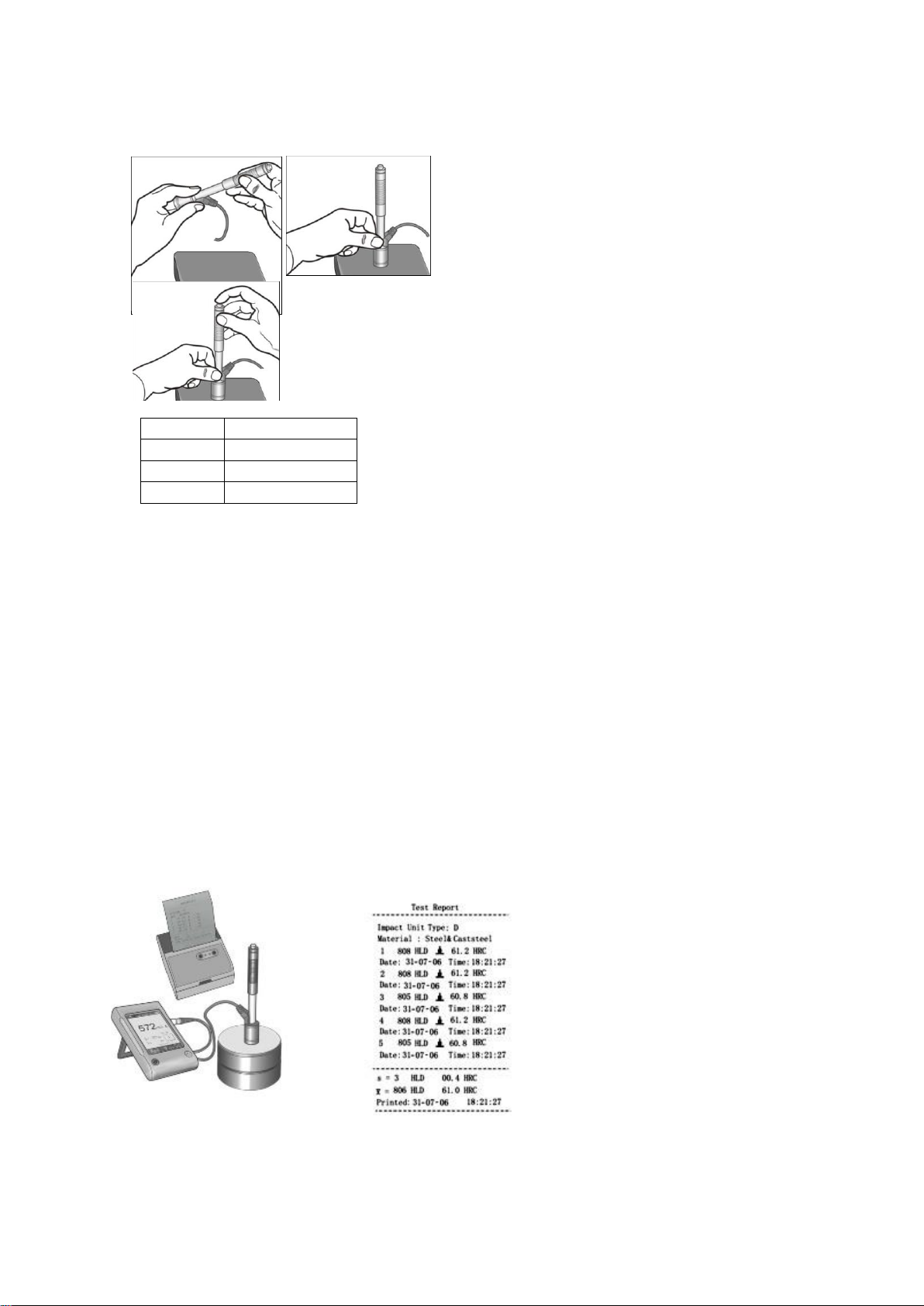

3.3 Test execution .......................................................................................................................... 8

3.4 Browsing ................................................................................................................................... 8

3.5 Print............................................................................................................................................ 9

4Setup............................................................................................................... 9

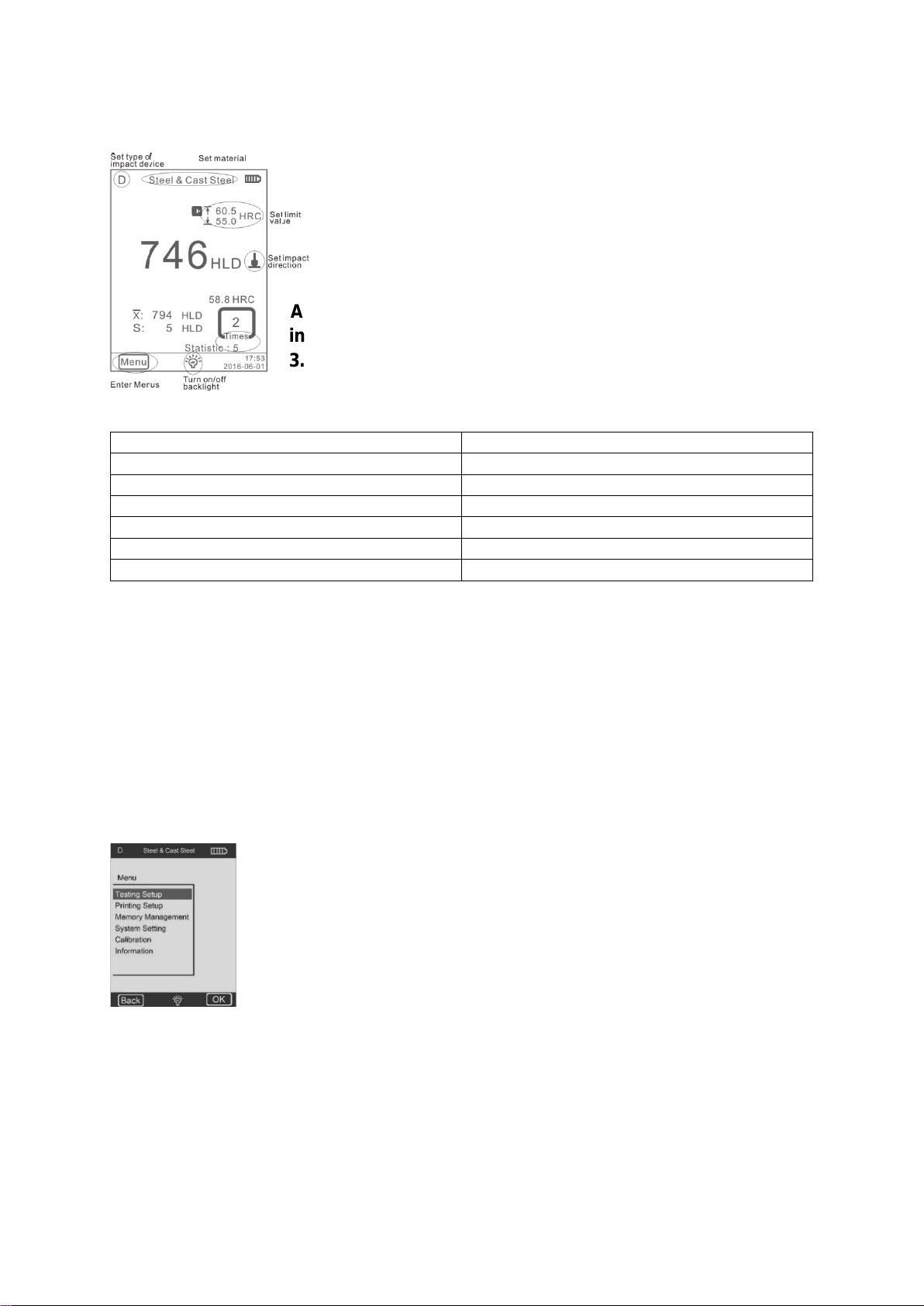

4.1 Settings in the main mask....................................................................................................... 9

4.2 Menu settings ......................................................................................................................... 10

5Care and maintenance................................................................................. 14

5.1 Periodic maintenance ............................................................................................................ 14

5.2 Store......................................................................................................................................... 14

5.3 Calibration............................................................................................................................... 15

6Annex............................................................................................................ 16

6.1 Conversion area ..................................................................................................................... 17

6.2 Scope of delivery.................................................................................................................... 17