TABLE OF CONTENTS

iii

2.3 Setting the AT10.1 parameters

2.3.1 Understanding parameter settings.................................................................30

2.3.2 Setting the Float and Equalize voltages.........................................................31

2.3.3 Setting the Equalize timer..............................................................................32

2.3.4 Setting the Alarms..........................................................................................32

Setting the high and low dc voltage alarms ...................................................33

Adjusting ground detection sensitivity............................................................34

Disabling the ground detection alarm ............................................................35

2.3.5 Setting the current limit value.........................................................................35

2.3.6 Enabling the high dc voltage shutdown feature.............................................36

2.3.7 Adjusting the Voltmeter accuracy ..................................................................37

2.3.8 Using the Low Level Detector (LLD)..............................................................38

2.3.9 Using the front panel security feature............................................................39

2.4 Performing routine maintenance ..........................................................................40

Sample preventive maintenance procedure.........................................................42

3Servicing the AT10.1 Battery Charger

3.1 A step-by-step troubleshooting procedure ...........................................................44

3.2 Interpreting front panel error messages ...............................................................45

3.3 Using the troubleshooting chart............................................................................48

3.4 Troubleshooting chart begins on..........................................................................49

3.5 Replacing defective components..........................................................................58

3.6 Ordering replacement parts..................................................................................62

Replacement parts tables (begin on)....................................................................62

APPENDIX A: AT10.1 Performance Specifications................................................................70

APPENDIX B: Field Installable Accessories...........................................................................71

APPENDIX C: Standard Drawings *

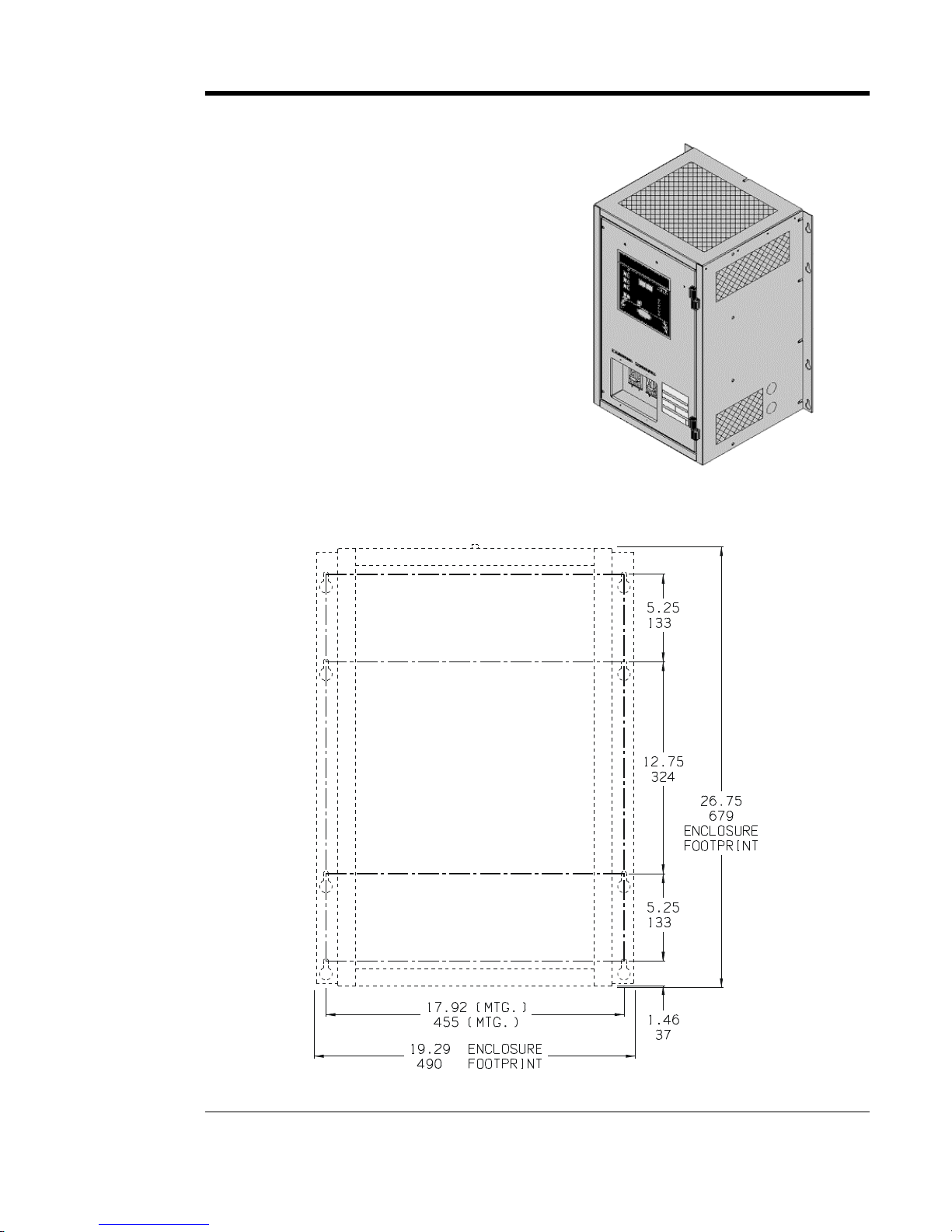

AT10.1 Series Battery Charger Outline: NEMA-1 Style-5017 Enclosure.....................................72

AT10.1 Series Battery Charger Outline: NEMA-1 Style-5018 Enclosure.....................................74

AT10.1 Series Battery Charger Internal Component Layout: Style-5017 Enclosure....................76

AT10.1 Series Battery Charger Internal Component Layout: Style-5018 Enclosure....................78

AT10.1 Series Battery Charger Instrument Panel / PC Board Detail...........................................80

Schematic -AT10.1 Group II Battery Charger -Standard w/o Options........................................82

Schematic -AT10.1 Group II Battery Charger -with Common Options.......................................84

Connection Diagram -AT10.1 Group II Battery Charger -Standard w/o Options........................86

Connection Diagram -AT10.1 Group II Battery Charger -with Common Options.......................88

Wire List -AT10.1 Group II Battery Charger................................................................................90

APPENDIX D: Recommended Float / Equalize Voltages.......................................................92

APPENDIX E: DNP3 Level 2 / Modbus Communications Module.........................................93

MANUAL SPECIFICATIONS (document control information / online availability) .....................94

* Note: A customized record drawing package is available for your AT10.1, featuring an itemized

internal component layout, electrical schematic with component ratings, and a full connection diagram.

If the standard drawings and wire list featured in this manual are not sufficient, please contact your Sales

Representative for drawing availability from the battery charger manufacturer.