Ventilstellantriebe

Valve actuators

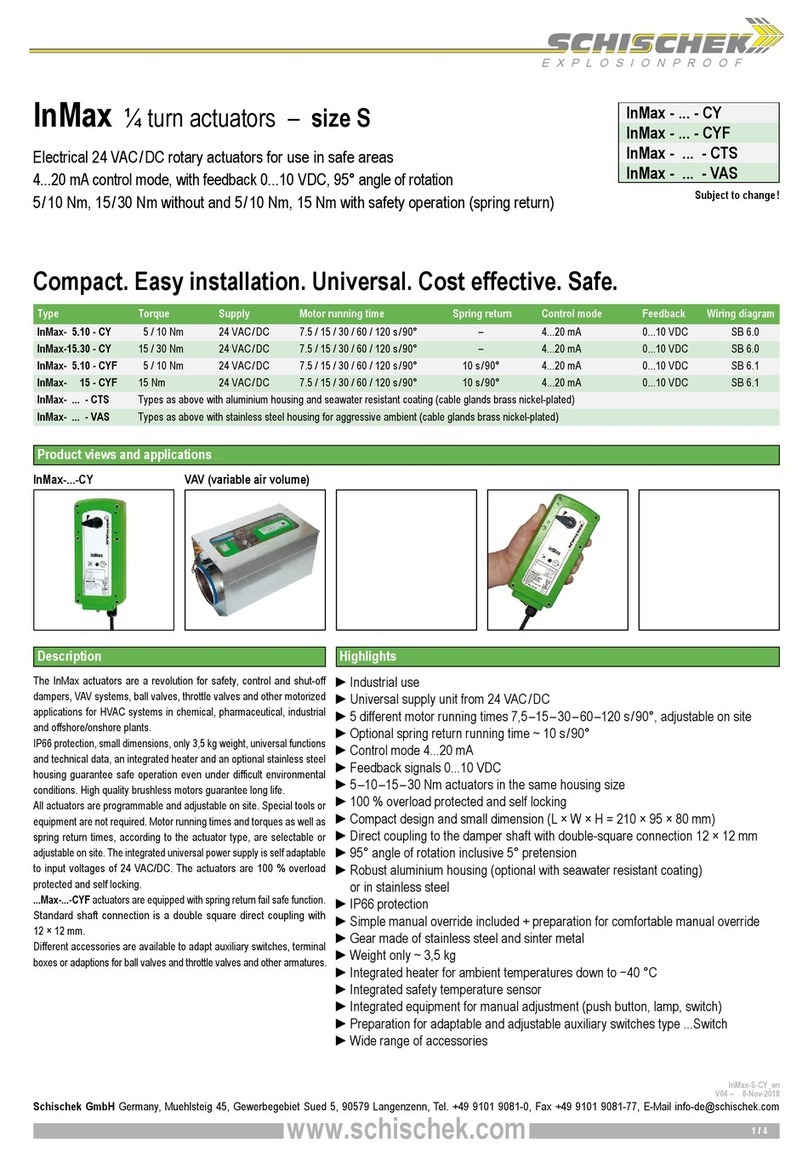

EXV-8/2024-Y

EXV-8/2024-Y/I

EXV-8/20230-Y

EXV-8/20230-Y/I

EXPLOSIONPROOF

Mounting instructions for the

valve body to the actuator EXV-...

1. The actuator will be delivered

with retracted stroke.

2. Place the actuator on the

valve body and attach with

the nuts and washers (1) provided.

3. Remove the cap nut (2) and

screw the connecting parts with

the connecting nut (3), taking

care not to damage the valve spindel.

The spindle should be retracted as

far as possible into the valve body.

4. Allow enough distance between

the threaded bolt head (4) and the

rod of the actuator, noting the travel

of the valve spindle. Any adjustment

can be done by screwing the bolt (4)

into the connection nut(3).

Tighten both counter nuts firmly.

5. Draw out the valve spindel with the

connecting parts until contact is

made to the threaded actuator rod

and join with the cap nut (2).

Do not overthighten (max. 4 m)

otherwise damage will be cause to

the mounting bracket.

6. onnect the actuator to the

supply in accordance with the

enclosed wiring diagram.

7. Operate the actuator electrically to

fully extend the actuators rod.

For modulated controlled actuator

with a 20 mA or 10 VD positioning

signal or by connecting to load via

terminal 4 (if no positioning signal available).

Visual check that the valve is closed.

Minor adjustment to the travel can be

achieved by turning the threaded bolt (4).

8. Secure all connections, take care not to

operate the actuator against the

stroke otherwise damage to

mounting bracket may occure.

9. The actuator is ready to operate.

Montage Ventilkörper an Antrieb EXV...

1. Der Antrieb wird werkseitig mit

eingefahrener Hubstange ausgeliefert!

2. Den Antrieb auf den Ventilkörper

stecken und mittels der mitgelieferten

Muttern (1) befestigen.

3. Überwurfmutter (2) lösen und

Verbindungsteile mittels der

Verbindungsmutter (3) locker auf

die Ventilspindel schrauben.

Ventilspindel dabei ganz hineindrücken!

4. Zwischen dem Schraubenkopf von

Schraube (4) und der Hubstange des

Antriebes entsprechend dem Ventilhub

Platz lassen, Ventilhub vorher messen und

notieren. Justage erfolgt über Schraube (4)

bzw. Verbindungsmutter (3).

5. Die beiden Kontermuttern (5)

handfest anziehen.

Die Ventilspindel mit den

Verbindungsteilen herausziehen und

mit Hilfe der Überwurfmutter (2) auf

der Hubstange befestigen.

icht zu fest anziehen (max. 4 m -

Zerstörung der internen Verdrehsicherung!)

6. Antrieb elektrisch nach dem Antrieb

beiliegenden Anschlußschema anschließen.

7. Antrieb elektrisch ausfahren lassen.

Bei Stetig-Antrieben mit Signal 20 mA bzw.

10 VD oder durch Auflegen der

Betriebsspannung auf Klemme 4 falls

noch kein Stellsignal vorhanden ist.

Funktion überprüfen - schließt Ventil?

Eine Nachjustage ist mittels Schraube (4) möglich.

8. Alle Verbindungen fest anziehen, dabei

darauf achten, daß nicht gegen die

Hubstange gekontert wird - Zerstörung der

internen Verdrehsicherung.

9. Der Antrieb ist betriebsbereit.

1-Mutter DIN934

Scheibe DIN125

Zahnscheibe DIN6797

2- Überwurfmutter

4-Schraube DIN912

5-Mutter DIN934

3-Verbindungsmutter

Verdrehsicherung

5-Mutter DIN934

Ventilspindel

Adapterdistanzsäule

Ventil

cap nut

threaded bolt

nut

connection nut

mounting bracket

nut

valve spindle

spacer rod

valve

nut

washer

toothed lock washer

EXV-...

Kontakt

switch

ab

Linearantrieb

linear actuator

Automatik

Automatik

Linearantrieb

linear actuator

Invers-Betrieb

reverse-function Brücke 2-4

connection 2-4

Normalbetrieb

normal function

Zwangssteuerungen

compulsion control

PE

1 2

EXV-...24-Y

EEx-e

45

PA

312

24 VA /D

36

YU

Y=2..10V

U=2..10V

4

Y

5

U

6

0

Y

1)

105X9-83

Y

Y

ba

reverse

hazardous area safe area

stetig

continuous

PE

2

EXV-...24-Y/I

EEx-e

45

PA

3

0

12

24 VA /D

136

YU

Y=4..20mA

U=2..10V

4

Y

5

U

6

Y/I

1)

105X9-76

Y

Y

ba

reverse

hazardous area safe area

stetig

continuous

PE

1 3

EXV-...230-Y

EEx-e

45

PA

312

230 VA

1236

YU

Y=2..10V

U=2..10V

4 2

U

3

7

PE

1

Y

NL

Y

1)

105X9-54

reverse

hazardous area safe area

stetig

continuous

PE

1 3

EXV-...230-Y/I

EEx-e

45

PA

312

230 VA

1236

YU

Y=4..20mA

U=2..10V

4 2

U

3

7

PE

1

Y

NL

Y/I

1)

105X9-50

reverse

hazardous area safe area

stetig

continuous

page 2 of 3

Elektrischer Anschluß "Y"oderY/I"

Electrical connection "Y"orY/I"

2003/05/22

SCHISCHEK GMBH D-90579 Langenzenn Mühlsteig 45 Gewerbegebiet V Tel.+49-(0)9101-90810 Fax +49-(0)9101-908177

Elektrischer Anschluß

Electrical connection

Für Inversbetrieb, Brücke 2 - 4 erforderlich.

onnection 2 - 4 for reverse function.

Y-

^Y

=Stellgröße

manipulated variable

U-

^Y

=Stellungsanzeige

feedback signal

Achtung/Attention: 24 V, Y & Y/I

Masse/Ground

Die beiden Masseleitungen 0 und 1 müssen eine

galvanische Verbindung haben. Diese Verbindung

sollte sich an der Stromversorgung oder am Regler-

ausgang befinden.

The two ground lines 0 and 1 must have an electrical

connection. This connection should be made at the

power supply or the controller output.

1

) optionale Heizung / optional heating