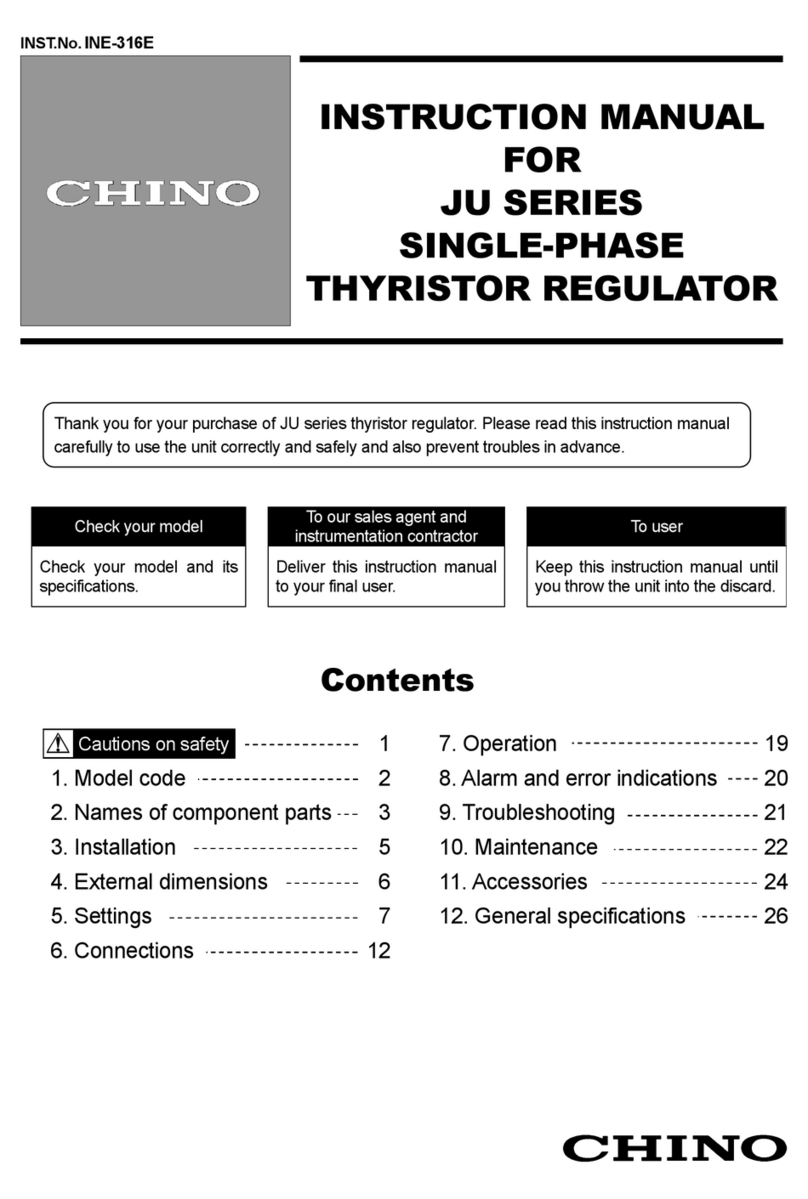

1. Introduction...................................................- 1 -

2. For safe use of the product.........................- 3 -

2.1 Prerequisites for use............................................ - 3 -

2-2. Symbol mark........................................................ - 3 -

2-3. Important .............................................................. - 4 -

3. Model code list..............................................- 5 -

4. Mounting and wiring....................................- 6 -

4-1. External dimensions.......................................... - 6 -

4-2. Mounting............................................................... - 7 -

4-3. Wiring.................................................................... - 9 -

5. Name of various parts................................- 20 -

5-1. Entire overview..................................................- 20 -

5-2. Overview of the front panel.............................- 20 -

5-3. Details of the front panel.................................. - 21 -

6. Operation screen........................................- 23 -

6-1.Output display screen.......................................- 23 -

6-2 Time display screen........................................... - 24 -

6-3 Program pattern overall display screen.........- 24 -

6-4. Output display screen of output 2 specifications - 25 -

6-5. Operation screen and setting screen............ - 26 -

7. Setting screen.............................................- 27 -

7-1. Basics of setting................................................ - 27 -

7-2. Mode 0 [Setting of parameters that are being

executed]............................................................- 29 -

7-3. Mode 1 [Setting related to operation status] - 31 -

7-4. Mode 2 [Setting related to program pattern] - 34 -

7-5. Mode 3 [Setting relate to PID and alarm].......- 38 -

7-6. Mode 4 [Setting related to output]..................- 43 -

7-7. Mode 5 [Setting related to input].................... - 47 -

7-8. Mode 6 [Setting related to time event]........... - 50 -

7-9. Mode 7 [Setting related to transmission output].- 51 -

7-10. Mode 8 [Setting related to communications] - 53 -

7-11.Mode 11 [Setting related to system]..............- 57 -

7-12. Mode 12 [Setting related to customer scale

correction]..........................................................- 60 -

7-13. Initializing the setup parameter ....................- 62 -

7-14. Precautions while setting.............................. - 63 -

7-15. Error message................................................. - 64 -

8. Initial settings..............................................- 67 -

9. Operation.....................................................- 68 -

9-1. Confirmations before operation..................... - 68 -

9-2. Program operation and run operation .......... - 68 -

9-3. Trial operation.................................................... - 71 -

9-4. Constant value operation................................ - 72 -

9-5. Automatic output operation and manual output

operation............................................................ - 73 -

9-6.Precautions during operation.......................- 74 -

10. Detailed explanation of main functions - 76 -

10-1 Measurement range ........................................ - 76 -

10-2 .Linear scale...................................................... - 77 -

10-3.Alarm mode...................................................... - 78 -

10-4.Auto tuning....................................................... - 85 -

10-5. PID control........................................................ - 86 -

10-6.Automatic PID switching system................. - 87 -

10-7. Actuator adjustment of ON-OFF servo type- 88 -

10-8. Output 2............................................................ - 89 -

10-9. Transmission signal output.......................... - 90 -

10-10. External signal input .................................... - 91 -

10-11. External signal output.................................. - 95 -

10-12. Timer slave synchronous operation ......... - 97 -

10-13. Communication interface........................... - 99 -

10-14. Customer scale correction........................- 100 -

11. Various type of option............................- 106 -

12. Engineering port.....................................- 118 -

13. Trouble shooting.....................................- 119 -

14. Checking and maintenance..................- 121 -

14-1. Checking ........................................................- 121 -

14-2. Life component.............................................- 121 -

14-3. Disposal..........................................................- 121 -

15. Explanation of terms..............................- 122 -

16. Accessories.............................................- 126 -

16-1. Front protective cover..................................- 126 -

16-2. Contact protection element.........................- 126 -

17. Specifications..........................................- 127 -

18. Parameter list..........................................- 131 -

19. Parameter directory list.........................- 137 -

20. Engineering unit sticker ........................- 139 -

Table of Contents