Smart-Till Orchard MaxT.G. Schmeiser Co., Inc.

Ph. (559) 268-8128

Fax (559) 268-3279

www.tgschmeiser.com

7

NO PASSENGERS ALLOWED

Do not carry passengers

anywhere on or in the tractor or

implement .

Read and Understand Manual

To prevent personal injury or even death, be sure

you read and understand all of the instructions in

this manual and other related OEM equipment manuals!

This equipment is dangerous to children and persons

unfamiliar with its operation . The operator should be a

responsible adult familiar with farm machinery and

trained in this equipment’s operations . Do not allow

persons to operate or maintain this unit until they have

read this manual and have developed a thorough

understanding of the safety precautions and how it

works .

This unit was designed for a specific application;

DO NOT modify or use this unit for any application other

than that for which it was designed .

Units operated improperly or by untrained personnel

can be dangerous!

GENERAL SAFETY

Fall Hazard

Do not use this implement as a work

platform . Do not stand on top of the unit at

any time . Do not ride on the tractor or the implement or

allow others to ride .

Crush Hazard

(Rolling Over)

To prevent serious

injury or death, before disconnecting, leaving the

operator’s seat, servicing, adjusting, repairing, or

performing other work on the implement, ALWAYS:

1 . Stop the tractor or towing vehicle .

2 . Shut off the engine and remove the ignition key .

3 . Set the brakes .

4 . Make sure wheel cylinder transport lock is

attached .

5. Relieve hydraulic fluid pressure.

STOP

0

ASSEMBLY SAFETY

Crush Hazard

Use support blocks or safety stands

rated to support the load when

assembling the unit or performing maintenance .

Never work under equipment supported by hydraulics .

Hydraulics can drop equipment instantly if controls are

actuated even when power to the hydraulics is shut off .

To prevent injury, use a tractor equipped with a

Roll Over Protective System (ROPS) .

Visually Inspect

Visually inspect the unit for any loose bolts,

worn parts, or cracked welds, and make

necessary repairs before using the unit .

Rolling Hazard

To prevent serious injury, lock the wheels when

performing assembly, maintenance, repairs, or

when preparing for storage.

Personal Protection Equipment

When working around or operating this unit, wear

appropriate personal protective equipment . This list

includes but is not limited to:

• A hard hat

• Protective shoes with slip resistant soles

• Protective goggles, glasses, or face shield

• Heavy gloves and protective clothing

• Ear muffs or plugs

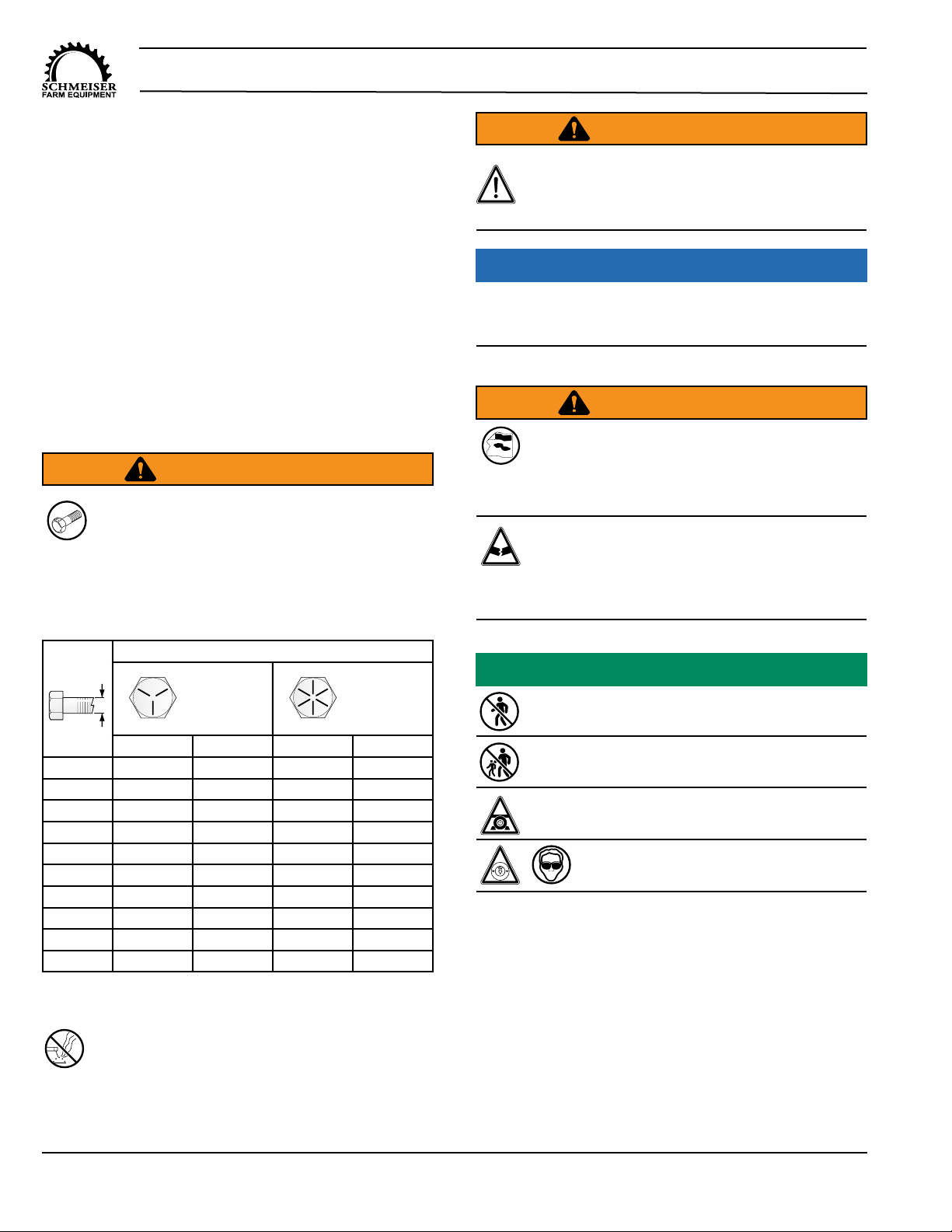

Use Properly Rated Tools

To prevent serious injury:

Use sufficient tools, jacks, and hoists

that have the capacity for the job .

Trapped Air Hazard

When installing, replacing, or repairing hydraulic

system cylinders or parts, make sure that the

entire system is charged and free of air before resuming

operations . Failure to bleed the system of all air can

result in improper machine operation, causing severe

injury .

Injury Hazard

Do not permit children to play on or around the

unit .

Impaired Operator Hazard

Do not attempt to operate this unit under the

influence of drugs or alcohol. Review the

safety instructions with all users annually .

Pinch Point /Sharp Object Hazard

Do not place any body parts between moving and /

or stationary parts . The weight of the implement will

easily cause serious bodily injury.