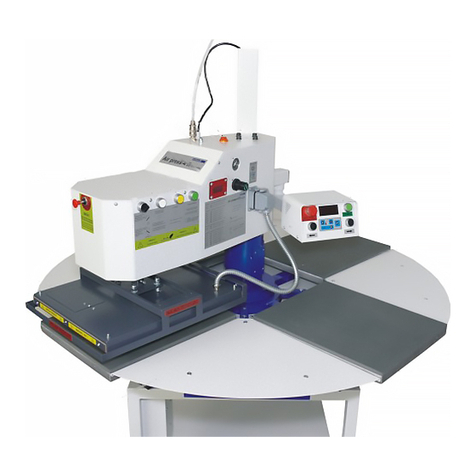

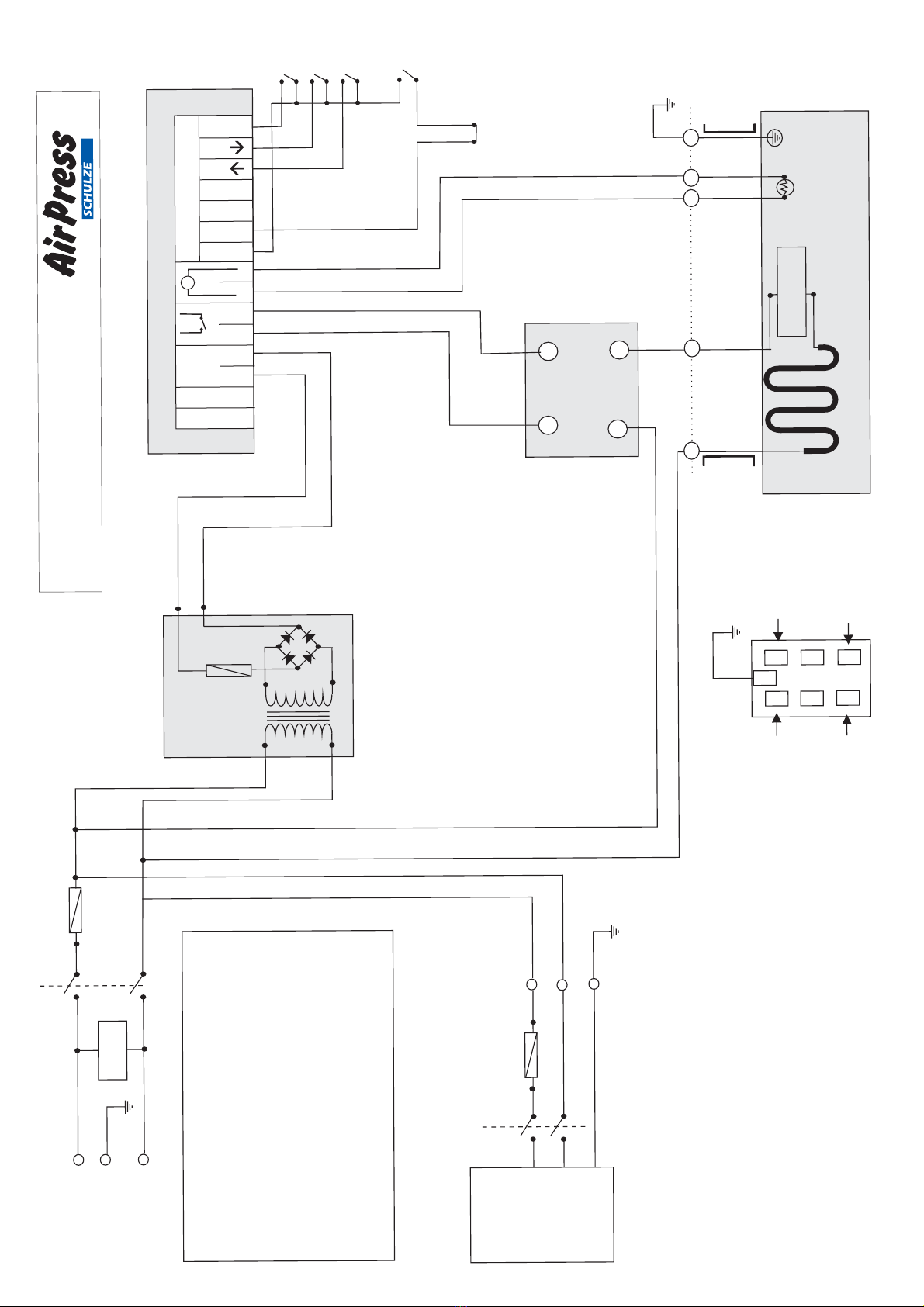

Pressure adjustment

Application pressure will change upon turning the right button: clockwise increases the pressure, opposite turn

the pressure. For storing the adjustment just press the button. Desiring to change the pressure just

The pressure can be read on the display top right:

1,0 bar = ca. 415kg

2,0 bar = ca. 830kg

3.0 bar = ca. 1245kg

4.0 bar = ca. 1660kg

5.0 bar = ca. 2075kg

6.0 bar = ca. 2490kg

It is recommended to adjust the pressure suitable to

to be done:

Cap options: 0.2 till max. 0.6bar

Platen 20 x20 cm 0.2 till max. 1.0bar

Platen 38 x 45 cm 0.5 4.0bar

Platen 40 x 50 cm 0.5 4.5bar

decreases

pull the button.

the work

till max.

till max.

After each and every change: the press should be closed for the reason of rechecking of the newly adjusted pressure.

Damages resulting from wrong pressure adjustments are excluded from warranty claims.

Switch ON

Before the press to be switched on first time, please check the plugin's proper conditions and also the safe

connection of the neutral cable.

Connect the hose of compressed air properly. Pressure should not exceed 6bar. Upon finish of operation please

disconnect the air pressure tube.

The press has to be switched on with the green rocker switch. The current temperature of the heat platen will be shown

on the display while heat will continously be developed until the chosen temperature has been achieved. (LED1 lights)

In case the press will be operated for several days uninterrupted, please drain the water out of the filter by push

the black button (left below the connection fitting) once a day.

Maintenance

Safety

For cleaning of the press we recommend a soft cloth. A mild household cleaner should maybe used in addition.

Please avoid usage of any scrubbing sponges, solvents and/or petrol.

Cleaning

Air pressure and power have to be disconnected before commencing any service work. Pull out the plug additionally.

For replacing/interchange of any platen please wait until the installed platen are cooled down entirely. Other wise

danger of serious burnings.

At the press are 2 grease nipples

The grease used should be temperature resistant up to 160C.

(left/right of the lower end of the tower) to be greased with a gease gun every 4 weeks.

Please make sure that the grease penetrates the bearings.

For optimal safety and performance please read these manual instructions thouroughly.

that operation of the press is permitted for one single person only. A sesond person should not even be around

in the action radius of the operator. please push the “emergency button” instantly. The press will then

be opened automatically, switches are blocked so that the press can not be moved downwards. For continuing work the

”emergency button” has to be pulled.

Please note

In case of an accident

Replacing silicone mat

Cap module:

Please note:

The press has to be cold for replacing the silicone mat.

Please make sure that the old mat has been removed entirely. Even small remaining spots of the old silicone mat and/or

adhesive have has to be cleaned up. Spread new temperature resistant silicone adhesive evenly with a spatula.

Then the new silicone mat has to be layed on the glued surface and right there after charge the whole mat with

a board (straightly) of + weight-load of ca. 20kg for about 24hours to set/drying-off duration.

The cold heat plate should be layed on the new silicone mat and smoothed together with a paper

tape, remaining for approx. 24 hours drying time

The silicone mat should be approximately 2cm larger (each dimension) than the base plate. To be cut to

measure by a clean sharp knife after the drying period.

2

The press should be operated by trained staff only and, of course, after acknoledging these manual intsructions.