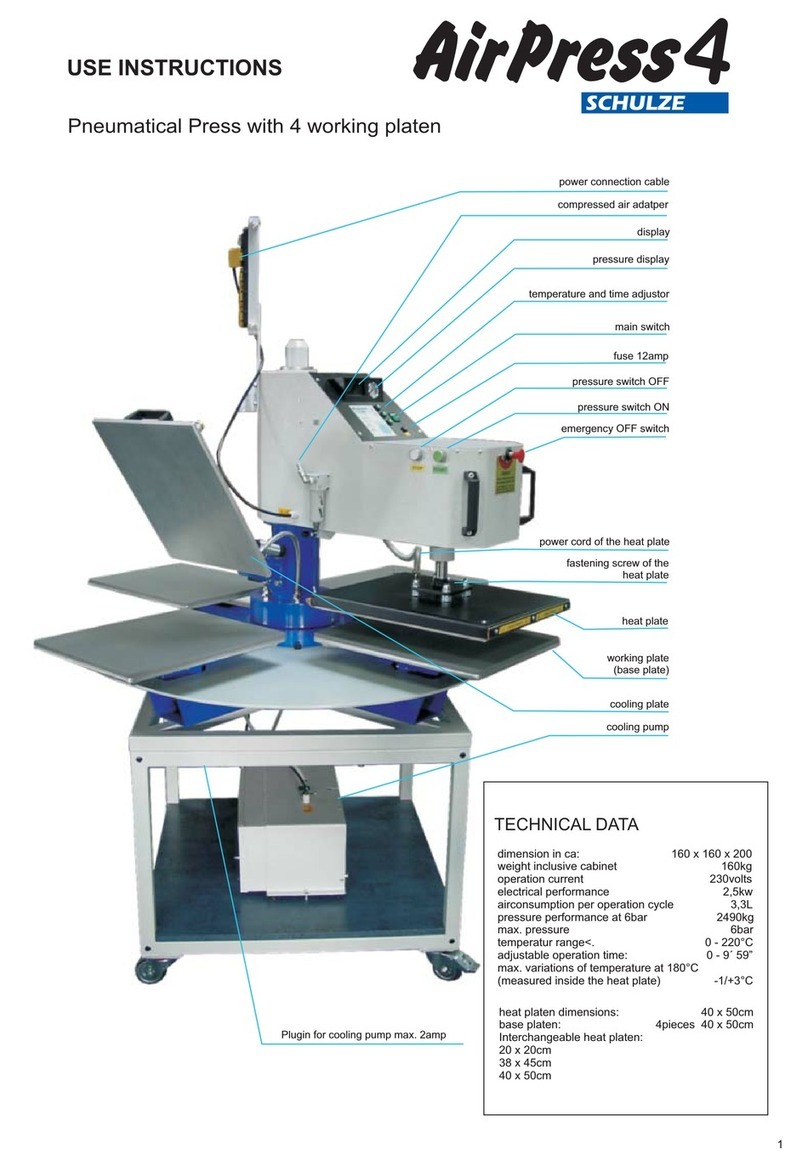

1.6 Replaceable base plates

For the heat press there are several base plates available.

The instruction for the replacement can be found in chapter

3. .

1. Membrane plate

2. Heating - base plate

3. Perforated plate

4. Base plate 40 x 50 cm

5. Base plate 38 x 45 cm

. Trapezoid plate 20 x 38 x 43 cm

7. Base plate 10 x 45 cm

8. Base plate 20 x 20 cm

9. Base plate for caps 10 x 13 cm

1.7 Protection of the device

The machine has been equipped with different safety arrangements, to assure a safety working procedure.

Main fuse B 16A

In case of overcharge, the main fuse prevents the heat press from getting damaged. Once the fuse was switched of, it has to be activated.

The instruction for activation of the main fuse can be found in the chapter 4.3.

Thermal fuse

The thermal fuse is situated directly on the heating plate and it stops the power supply if the temperature exceeds ~2 0°C. If the fuse is

activated, the temperature sinks down to 90°C. After that the power supply gets activated again and the temperature of the heating plate

rises and it’s possible to continue the work with the press. Over time the thermal fuse may wear out and cut off the power supply by lower

temperature, for example by 180°C. In such case it’s needed to replace the thermal fuse as soon as possible. The instruction for the

replacement of the thermal fuse can be found in chapter 4.9.

Automatic switch-off

If the press doesn't get opened within 10 seconds after the pressing progress, the heating element switches off automatically, to avoid fire

danger.

Emergency button

The emergency button has been installed to eliminate the residual risks. In case of emergency push the red emergency button. It is

situated in front of the press. The press will open automatically. To resume work, the button has to be pulled back again.

Mechanical emergency button

If the emergency button doesn’t work due to power failure, the machine switches automatically to the mechanical emergency mode. This

mode allows to stop the work of the machine. The press will open automatically using an independent mechanical system.

1.8 Safety arrangements at the workplace

Set-up and installation

Set-up and installation of the device has to be done under supervision of an authorized person by the company owner. Depending on the

model and weight of the heat press, the installation has to be done by 2 or more persons. The press should be situated on the flat, non-

inflammable surface, in a room with constant temperature and constant moisture. Keep the machine away from dusty rooms, because dust

could have a negative influence on some parts of the machine. Very important! The machine may be connected only to an installation

provided with a protection against electric shock. The machine is destined for industrial use only.

Testing the machine

After the correct installation of the machine it is important to ensure that the machine works properly, is not damaged after the

transportation and has no safety defects. The testing can only be done by the employer or other authorized persons. It is mandatory to

guarantee a correct installation and safe usage of the machine. After receiving the machine, check the packaging. The testing should be

protocoled. If any irregularities regarding functionality or safety are found during the testing, these has to be noted and reported to Walter

Schulze GmbH in written form within 7 days. Until the clarification the machine can not be used.

Information and education

According to §81 the industrial law and § 14 employment protection law (german law), the advice from he producer and general safety

arrangements at the workplace, the employer has to make arrangements to give all information about the safety, function and the range of

application to the user. In particular the user needs to be acquainted with the complete manual and be explicitly informed of the dangers of

working with the machine. The details have to be explained in a coherent form and language. Every user is obligated to a safe usage of the

machine and to read the manual instruction before each operator starts working with the machine. Using the machine, means that the

operator has read the instruction and is aware of the possible risks of working with the machine.

Safety

In order to ensure optimized safety, please read the manual instruction precisely. Only one person is allowed to work on the machine at a

time. The machine has to be under supervision the whole time, when it’s working. Supervise the machine till it is switched off and the plug

is pulled out. Pressure adjustment has to be done when the press is open. There should be no unauthorized persons near the machine

while it’s working. Beware of the heating plate – risk of burns. It is allowed to use personal protective equipment. Attention! The press

opens automatically – keep the safety clearance. In case of emergency or a dangerous situation, please push the emergency stop switch.

It is situated in the front of the press. The machine will stop immediately. The plug has to be pulled out of the power supply, while

maintenance. Using the press with certain materials may create a strong smell. That’s why the operator should evaluate the need for a

ventilation system at the workplace. The type of ventilation should be used as needed and depends on the size of the room and used inks.

The space in front of the press has to be wide enough to let nothing disturb the user at work. The press has to be installed at a place which

gives enough space on both sides to put the material on. Do not install the machine in doors. Floors or busy places. All wires should be

placed in a safe way, to make sure they will not pose a threat for the person working at the machine or passing it. In case of damage the

wires, stop work, turn off the press, unplug the machine and contact the service. All repairs should be performed after consulting the

service. Do not remove machine covers while the machine is working.

Version 21.02