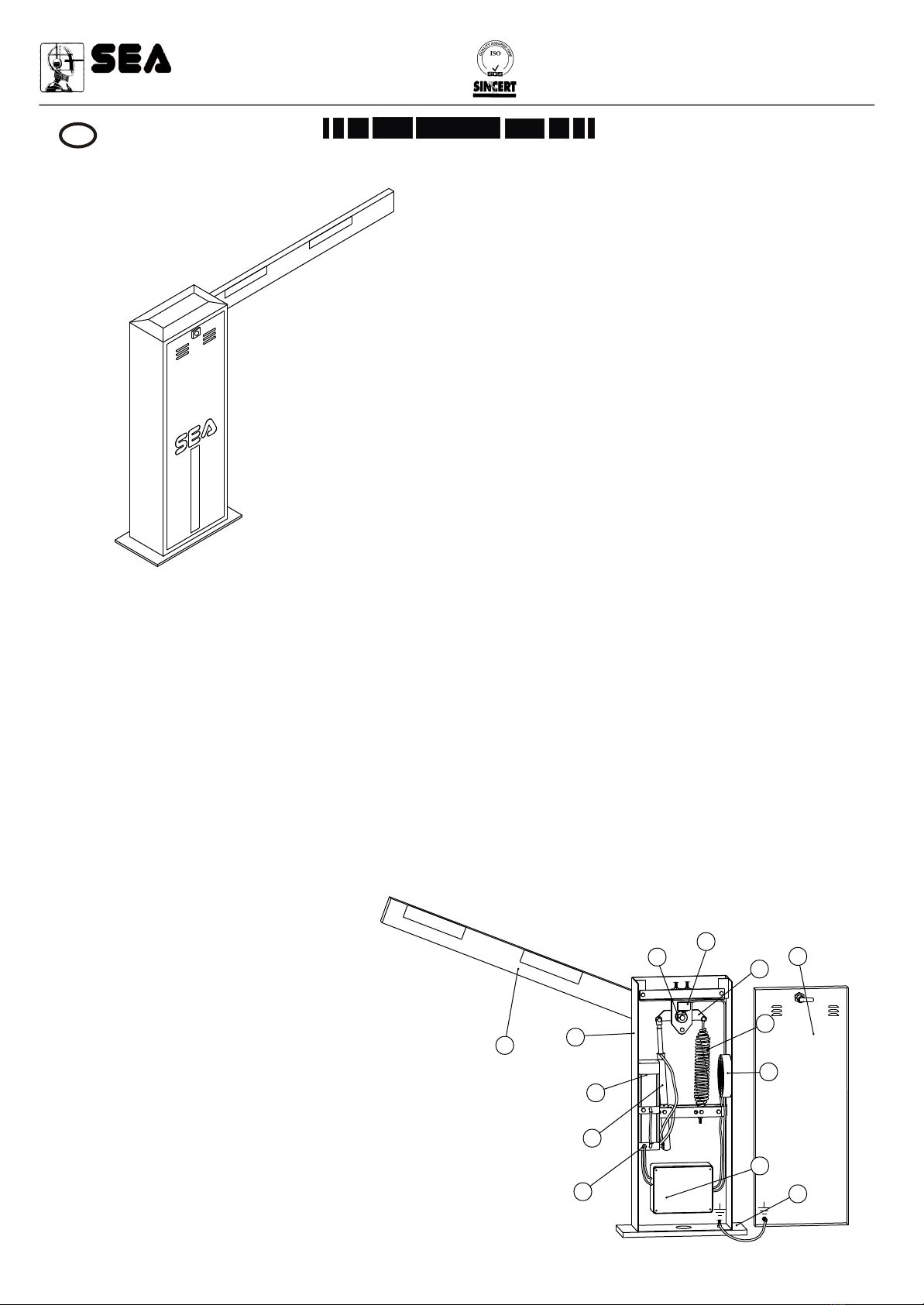

SEA VELA RAP 11705010 User manual

VELA RAPIDA

INSTALLATION MANUAL

BARRIER Mod. : “VELA RAP

11705010”,”VELA RAP 11705011”, “VELA

RAP 11705110”,“VELARAP 11705111”

Cod. 67410290 Rev. 02 , 05/2001

D.D.M.T.A.T.GiampieroScarpone15/02/00

Sea s.r.l. is happy to congratulate and thank you for choosing our product. Your choice

will allow you to understand how our factory, according to studies, research and above

all the needs of our clients, wants to gather technology, reliability and safety together

keeping in mind use and installation easiness.

General characteristics

VELA Rapid is a hydraulic barrier (2 -2.5 - 3 m) for the automation of all those

entrances where intensive cycles and high opening/closing speed are necessary

(parkings, motorways, airports ...). It is provided with an anti-crush device that ensures

a strength not higher than 15 Kg on the beam so to ensure people and things against

accidents. An accurate slowing down system guarantees the total control of the

momentum strength. The manual release makes the beam independent from the

hydraulic unit so to allow the manual closing and opening.

The automation is constituted by:

1Limit Switch cam, with the aim of operating the micro switch intervention.

2Micro Switch for limit switch, which allows to regulate the system slowing down time.

3Steel beam balance assembly coated with zinc.

4VELARapid case lid provided with lock with personalized key from 1 to 32.

5Balancing spring which is available in 2 different sizes so to accomplish with the 3 beam lengths (See spring tab.).

6Electro-fan.

723010016 electronic control unit, an advanced device which allows for the programming and control of all working and

safety systems.

8Mounting plate built with steel coated with zinc.

9Sensor for hydraulic unit temperature monitoring and starting up cooling fan.

10 Double effect hydraulic piston wich gives movement to the beam by the beam balance assembly.

11 Hydraulic unit with manual release for the manual opening of the beam in case of damages and two screws for couple

adjustment.

12 Vela Rapid case wich protects all mechanic and electric devices from atmospheric agents. It is made by a steel sheet

wich is processed with cathaphoresis and epossidic dust painting. On request SEAprovides the inox steel case.

13 Beam in extruded aluminium, available in 3 sizes: 2, 2.5 and 3 m.

11

22

33

44

55

66

77

88

99

1010

1111

1212

1313

Name of the most important parts:

1 Limit Switch cam

2 Micro Switch for Limit Switch

3 Beam balance assembly

4 Vela Rapid case lid

5 Balancing spring

6 Electro-fan

7 23010016 Electronic Control Unit

8 Vela Rapid mounting plate

9 Temperature sensor

10 Piston

11 Hydraulic pump unit

12 Vela Rapid case

13 Aluminium beam

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

GB English

Voltage supply

Absorbed current

Motor power

Motor revolutions

Operating temperature

Thermal cut out

Pump rating

Opening\closing time

Protection class

Manual release device

Use frequency

Capacitor

Hydraulic piston

Anti-crush system

Lock system

Slowing down

Cooling system

Fan intervention temperature

Hydraulic oil

Operating pressure

Max pressure

Barrier case treatment

Beam length

Weight

Electronic Control Unit

: 230 Vac ± 5% - 50/60 Hz single phase

: 1,8 A

: 320 W

: 2800 RPM/min.

: -25 + 70°C

: 130°C

: 2 l./min.

: 1,6 s

: IP55

: Hydraulic

: 100%

: 35 uF 450V

: d 35mm

: No. 2 by-pass valves

: Opening and closing hydraulic one

: Hydraulic

: By forced air with electro-fan

: 65°C 55°C(OFF)

: SEA Verde

: 20 bar

: 50 bar

: cathaphoresis and epossidic dust painting RAL3000

: 2 - 2,5 - 3 m

: 65Kg

: for Rapid barrier (Cod.23010016)

Technical data:

BEAM TABEL

Beam Length

L (m)

2

2,5 - 3

Spring

6

6,5

Spring code

66400050

66400055

Dimensions:

Cod. 67410290 Rev. 02 , 05/2001

30

3

250

1000

320

00

4

765

5

28

L

Beam

25

85

2

3

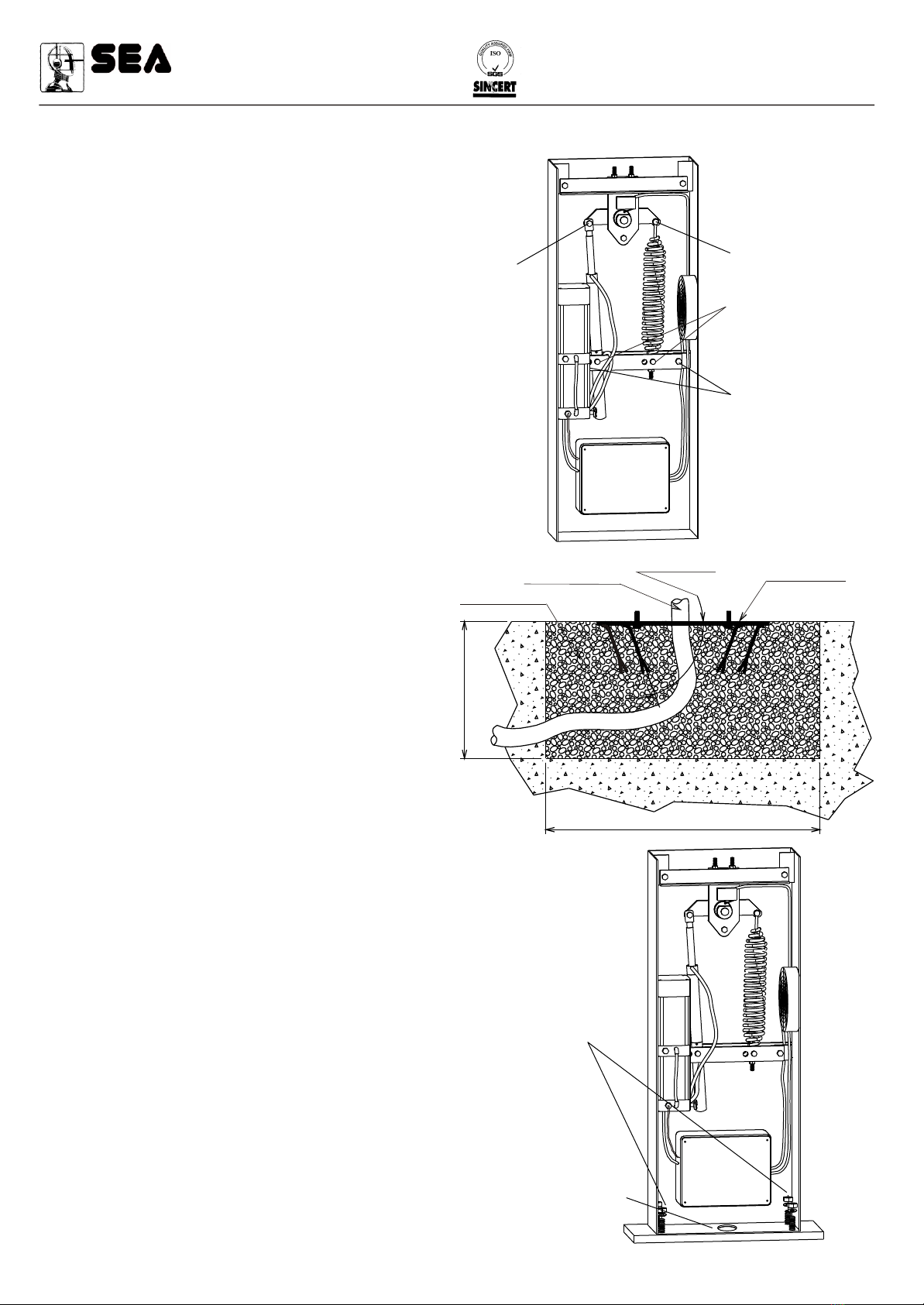

1) Position of spring and piston

The versatile barrier you are going to install allows for left or right closing

according to requirements. To make sure that the barrier closes your

desired side open the carter and check that the piston is on the side you

like.

Ex. With right hand piston the closing is on the right (Fig 1 and 2).

If the barrier provided does not close your desired side you can invert it

following the instructions we are going to provide.

Fig.1

Right hand closing barrier

Fig.2

Left hand closing barrier

FITTING INSTRUCTIONS

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

Ex. With right hand piston the closing is on the right.

"Remove the spring and piston fixing screws.

"Remove the bracket by unscrewing the bolts

shown.

"Position the piston on the right hand side (where the

spring is fixed) and fix it to the beam balance assembly

by the screw.

"Position the spring on the left hand side (where the

piston is fixed) and fix it to the beam balance assembly

as well.

"Fix the bracket where it was placed before, keeping

in mind that the external holes are for the spring

anchorage pin, while the internal ones are for the piston

pin, both in case of necessity of right closing, and in

case of necessity of left closing.

Cod. 67410290 Rev. 02 , 05/2001

Piston fixing

screws

Spring fixing

screw

Fig.3

Bracket fixing

screws

Anchorage

pins

ConcreteConcrete

Foundation plate to

be levelled

Foundation plate to

be levelled

Clamps 60°~

Clamps 60°~

Wire sheathingWire sheathing

600600

400

400

2) Mounting plate fixing

-Dig a hole 600x600x400 mm.

-Widen the foundation plate clamps at 60° (Fig. 4).

-Fill the hole with R425 concrete and place the

foundation plate as in Fig. 4 .

-Level the plate with care.

*The plate has got a central hole for electric wiring so

put an electric wire sheathing in the hole before filling the

hole with concrete.

Fixing nuts

& bolts

Hole for wire

sheathing Fig.5

Fig.4

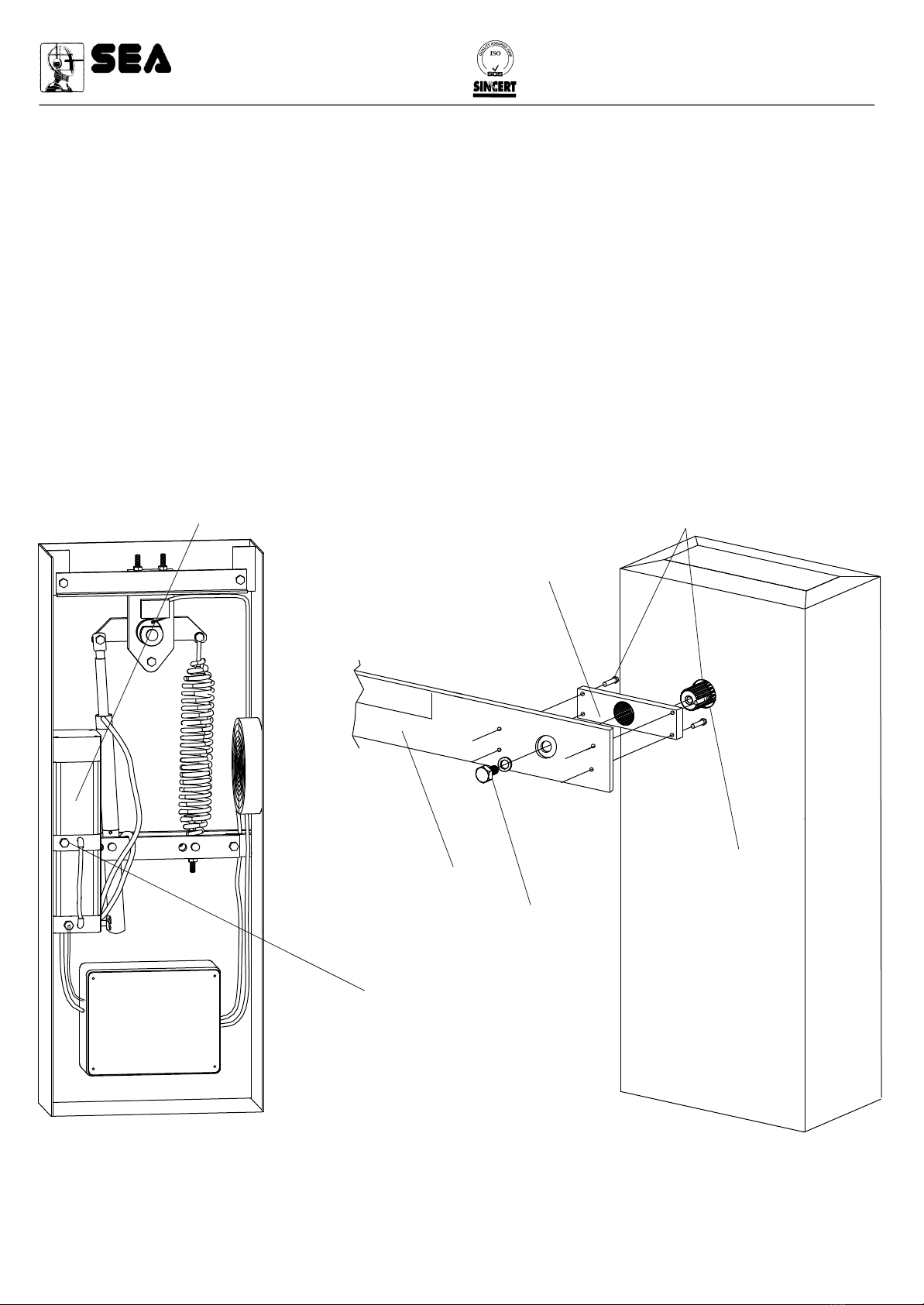

3) Fixing the column on the foundation plate

-Place the column so that the holes at the base correspond

to the screws that emerge from the foundation plate.

-Make sure that the wire sheathing is fixed on the big

central hole at the base of the column.

-Tighten the column to the foundation plate screwing the

provided nuts and bolts with care.

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

4) Oil Filler plug

When the barrier has been bolted down to the ground remove the oil reservoir transport plug from the frontal part of the

hydraulic pump unit (Fig.6) and replace it for the breather plug supplied with the system.

5) Mounting the beam

-Insert to one end of the splined shaft the beam perfectly vertically positioned.

-Fix the beam using the bolt and washer supplied (Fig. 7).

N.B.: The beam is supplied with the anchorage bracket already fixed. Should that not be the case, fix it by the screws supplied.

Cod. 67410290 Rev. 02 , 05/2001

Oil filler plug

to be replaced by

the breather cork

before working

Hydraulic pump

Bracket for

beam fixing

Screws for

bracket/beam fixing

Splined shaft

Tightening screw

and washer

Beam

Fig.7

Fig.6

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

Cod. 67410290 Rev. 02 , 05/2001

6) Balancing the spring

-Turn the manual release valve anti-clockwise to

release the hydraulic locking so that the beam can

be opened and closed manually.

-Lift the beam to an angle of approximately 45

degrees.

-Tight or untight the spring adjusting bolt locknut so

that the spring reaches a balance point with the

0

beam at 45 (Fig 8). If the beam is correctly

balanced it should stay stopped in position

(Fig.8).

-After balancing fix the spring adjusting bolt

locknut with the bolt and block the hydraulic unit.

7) Slow down adjustment: hydraulic

Spring tension

adjusting bolt

Spring bolt locknut

Hydraulic pump

manual release

Fig.8

Hydraulic pump unit

45

45

15

15

Cam adjusting screws

Fig.9

8) Barrier power supply

You can now feed the barrier with 230Vac 50/60 Hz power supply.

Check “Wiring the connectors” (paragraph 12) for more details.

9) Force adjustment

If necessary the piston force can be adjusted by the two adjusting

screws (grey to open and yellow to close) placed on the front lower

place of the hydraulic pump unit (Fig. 9).

*The automation is adjusted at 15 Kg force ex works so to guarantee

the anti-crush safety. We recommend to adjust it only in case of

necessity.

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

Cod. 67410290 Rev. 02 , 05/2001

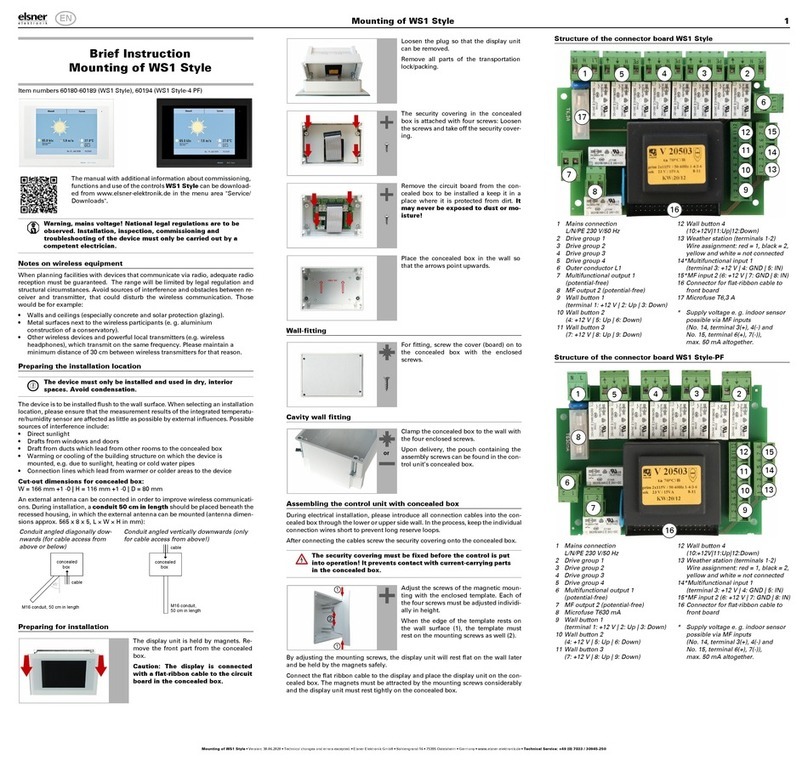

10) Levelling the beam

This manoeuvre must be done only if the beam is not perfectly horizontal in closing or vertical in opening at the end

stroke.

-Unlock the hydraulic unit by the release screw so that the beam opens and closes manually.

-Release the end stroke screws unscrewing the lock nuts on the beam balance assembly (Fig.10).

-Screw or unscrew the end stroke screws so that the beam stays perfectly vertical in opening and perfectly horizontal in

closing (Fig.10).

-After levelling, fix the end stroke by tightening the lock nuts on the beam balance assembly and block the hydraulic unit.

Limit Switch adjustment screws

Tightening bolts

Beam balance assembly

Fig.10

11) Wiring

In Fig. 11 you find the wiring necessary for the barrier installation.

The two numbers placed nearby the electrical cables show their quantity and section.

11

2233

44

55

66

77

88

2x1 3x1

2x1

2x1

4x1

3x1,5

3x1

Legend:

1- Vela Rapid electronic

control unit

2- Photocell (transmitter)

3- Photocell (receiver)

4- Key switch

5- Radio receiver

6- Warning light

7- Push button board

8- Differential switch

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

Cod. 67410290 Rev. 02 , 05/2001

12) Connectors connection

The electronic control unit Mod.23010016 is located inside the box. The panel controls all the device functions. It is

technologically advanced and you will choose the logic function that suits you most.

The electronic control unit is provided of two comfortable plugged-in wiring boards; one for low tension, the other for 230V

power supply.

1 2 3 4 5 6 7 8 9 10 11 121 2 3 4 5 6 7 8 9 10 11 12

Open

Close

Stop

Photo

Safety

End Stroke

0V

+24V dc 300 mA Max

Indicator lamp 24V dc(+)

Max1W

- - - -- - - -

LOW TENSION WIRING BOARD CONNECTIONS

-The safety entrance (8/9 usually closed) if activated inverts temporaneously the beam movement.

-The stop entrance (3/4 usually closed) if activated stops the automation anytime.

-The photocell entrance (9/10 usually closed) if activated while closing inverts the beam movement; if activated while

opening it is ignored.

!In case stop, photocells or safety are not connected it is necessary bridging their wire boards (3/4, 5/6, 8/9). Photocells

wiring boards (5/6) must be bridged even if a photocel plug-in board is being used.

WIRING BOARD 230Vac CONNECTIONS

1 2 3 4 5 6 7 81 2 3 4 5 6 7 8

M1M1

Service relay exit 230V

230V ac

NNFF

230 Vac warning light

with lighting board

(code 23104065 and 23104005)

Motor

Com.

blue

Please note: check the manual “Electronic unit” for more information about programming and working logic.

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

Cod. 67410290 Rev. 02 , 05/2001

WARNING

The electric installation and the working logic choice must be done according to the existing laws. A 6A Fuse (or MCB) and a

16A - 0,030A trip must be incorporated into the source of the gate main electrical supply. Keep the power cables (motors,

power supply) and the control ones (push buttons, photocells, radio etc.) separated. You can use two different sheaths to avoid

interference.

Note: Use “cable clips” and/or “duct/box pipes” fitting close to the control panel box so to protect the interconnection cables

against pulling efforts.

INTENDED USE

The Vela Rapid has been designed to be solely used to automate barriers.

SPARE PARTS

To obtain spare parts contact:

SEAs.r.l. Zona Ind.le, 64020 S.ATTO Teramo Italia

SAFETYAND ENVIRONMENTAL COMPATIBILITY

We recommend not to spoil the environment with product and circuit packing material.

CONFORMITY REQUIREMENTS

The VELARAPID operator conforms to the following:

- 89/392/CEE (Machine Directive)

- 89/336/CEE (Electromagnetic Compatibility Directive)

- 73/23/CEE (Electric Safety)

STORAGE

STORAGE TEMPERATURES

Tmin

-40°C

Tmax

+80°C

Humiditymin

5% no condensation

Humiditymax

90% no condensation

When being transported this product must be properly packaged and handled with care.

MAINTENANCE AND OUT OF SERVICE

The decommission and maintenance of this unit must only be carried out by specialised and authorised personnel.

LIMIT OF GUARANTEE

Vela Rapid is guaranteed for a period of 24 months. The guarantee period starts from the date stamp printed on the unit. The

guarantee will be void if the unit has been incorrectly installed, not used for the purpose intended, tampered with or modified in

any way.

The validity of this guarantee only extends to the original purchaser of the unit.

NOTE: THE MANUFACTURER CAN NOT BE DEEMED RESPONSIBLE FOR ANY DAMAGE OR INJURY CAUSED BY

IMPROPER USE OF THIS PRODUCT.

SEA reserves the right to modify or adjust the products and information provided in this manual with no obligation to

notice.

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

DIREZIONE E STABILIMENTO:

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

http://www.seateam.com

9001

CE

This manual suits for next models

3

Table of contents

Other SEA Control System manuals

Popular Control System manuals by other brands

SIMARINE

SIMARINE SC302T user manual

Elsner

Elsner WS1 Color Brief Instruction

ADB Safegate

ADB Safegate RELIANCE Navigator user manual

Rottler

Rottler F103 Series Installation guide, operation and maintenance manual

Bryan Boilers

Bryan Boilers CL Series brochure

Joyonway

Joyonway PB554 Simplified operation instruction