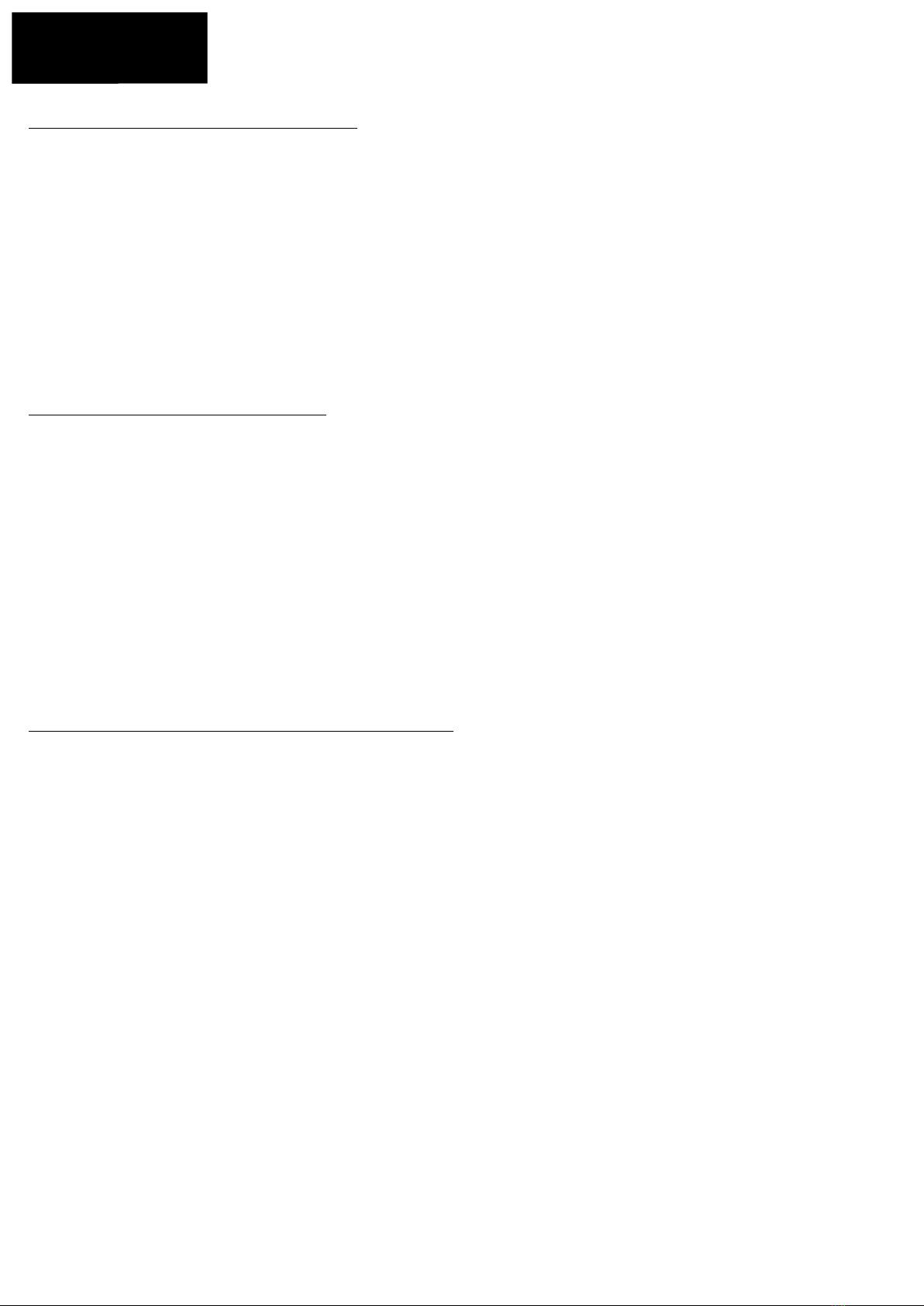

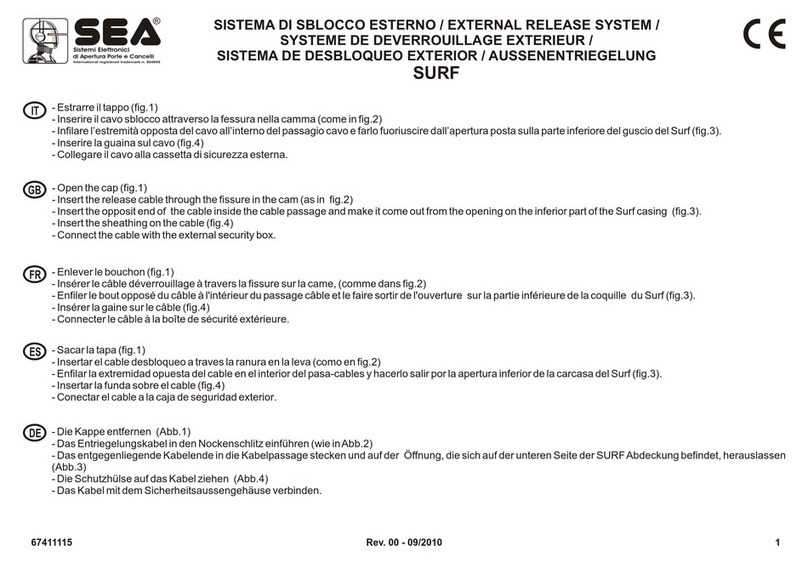

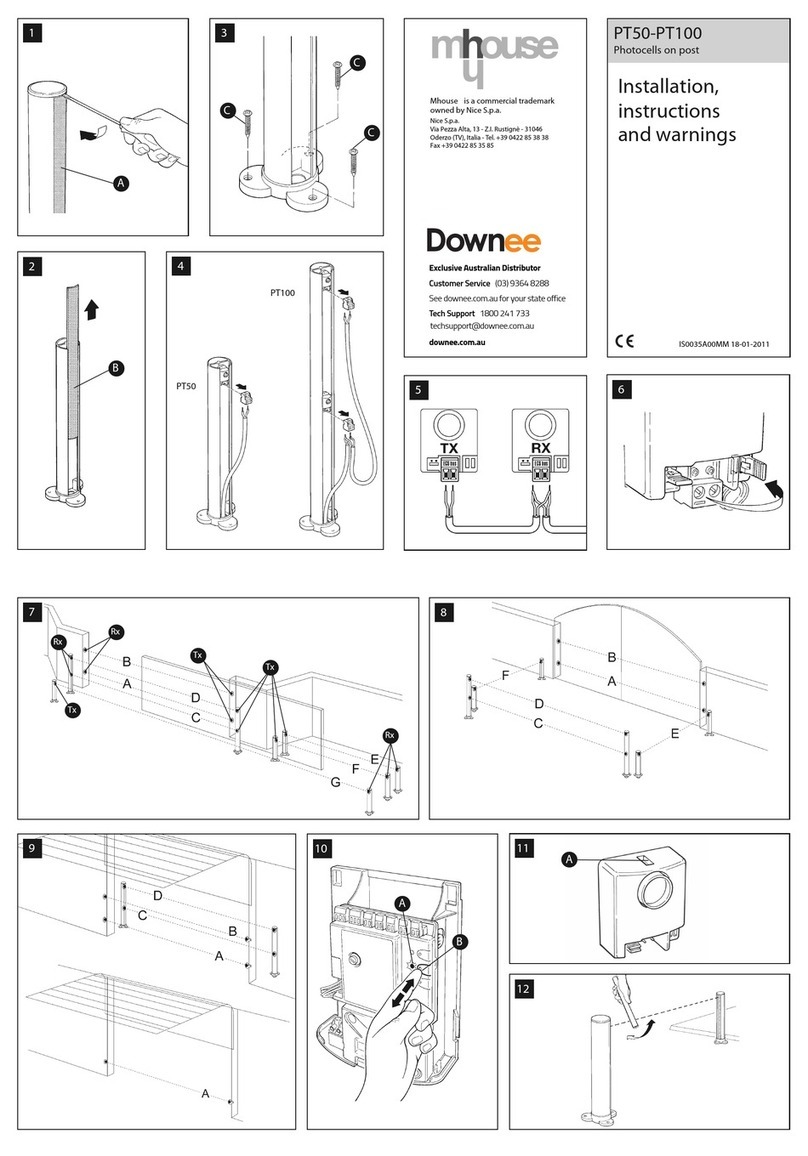

i) For gate operators utiliing a non-contact sensor:

See instructions on the placement of non-contact sensors for each Type of application

2 Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the

gate is still moving

3 One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier

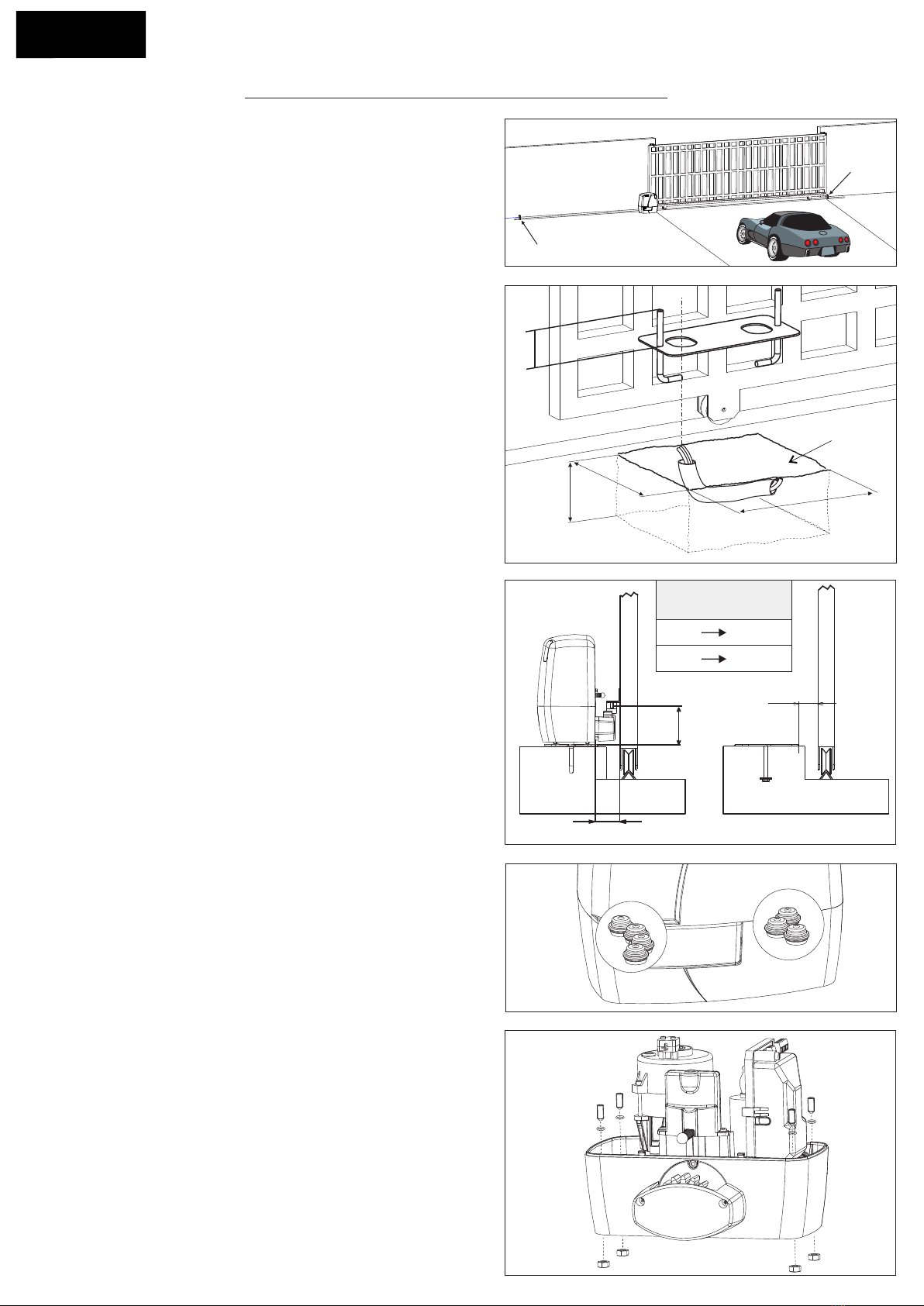

) For a gate operator utiliing a contact sensor:

One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the

leading edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

2 One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3 One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4 A hardwired contact sensor shall be located and its wiring arranged so that the communication between the

sensor and the gate operator is not subjected to mechanical damage.

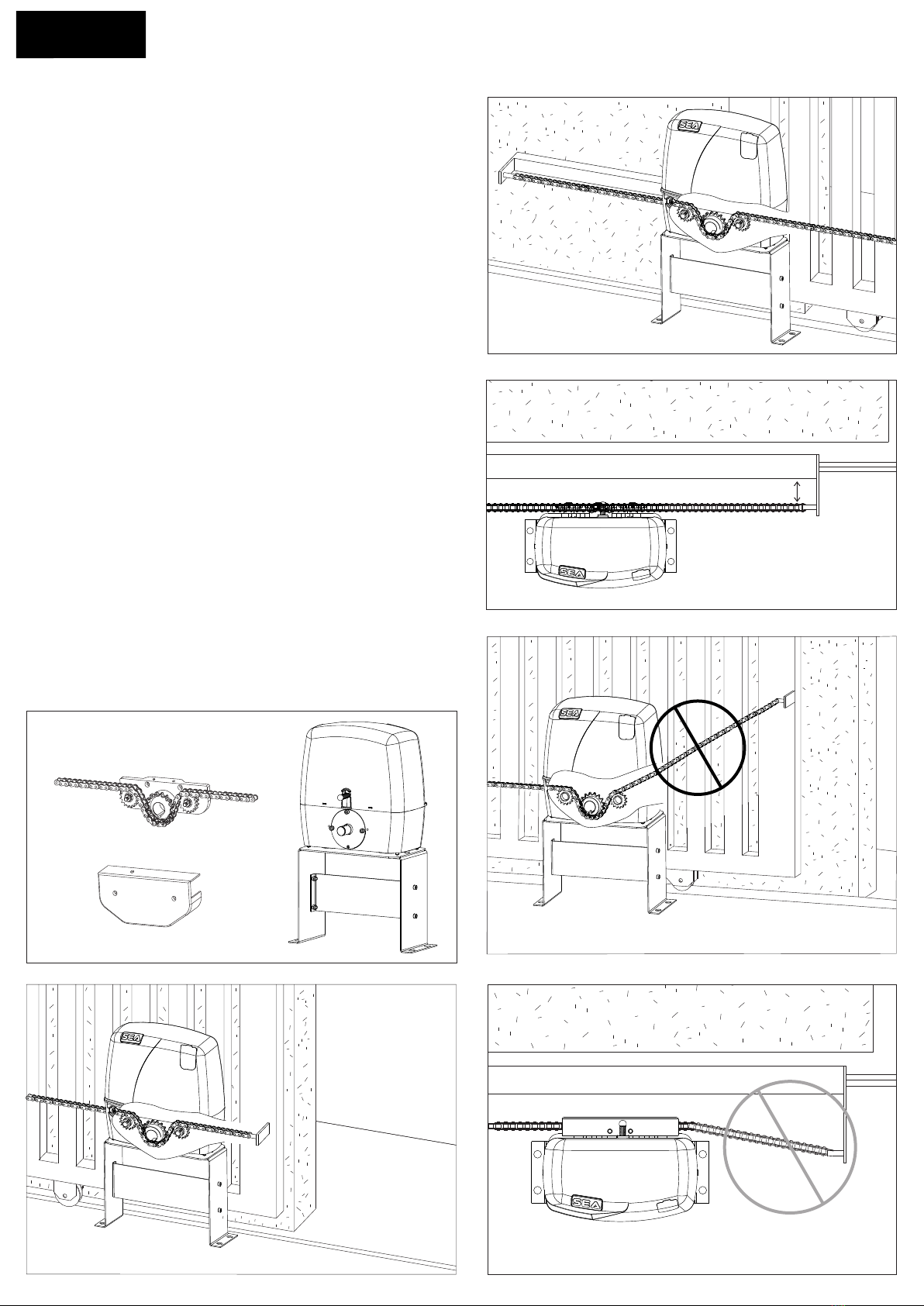

5 A wireless contact sensor such as one that transmits radio frequency RF signals to the gate operator for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall

function under the intended end-use conditions.

6 One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally,

if the bottom edge of a swing gate is greater than 6 inches 52 mm above the ground at any point in its arc of

travel, one or more contact sensors shall be located on the bottom edge.

7 One or more contact sensors shall be located at the bottom edge of a vertical barrier arm.

Instruction regarding intended operation of the gate operator shall be provided as part of the user instructions or as a

separate document. The following instructions or the equivalent shall be provided

NOTICE

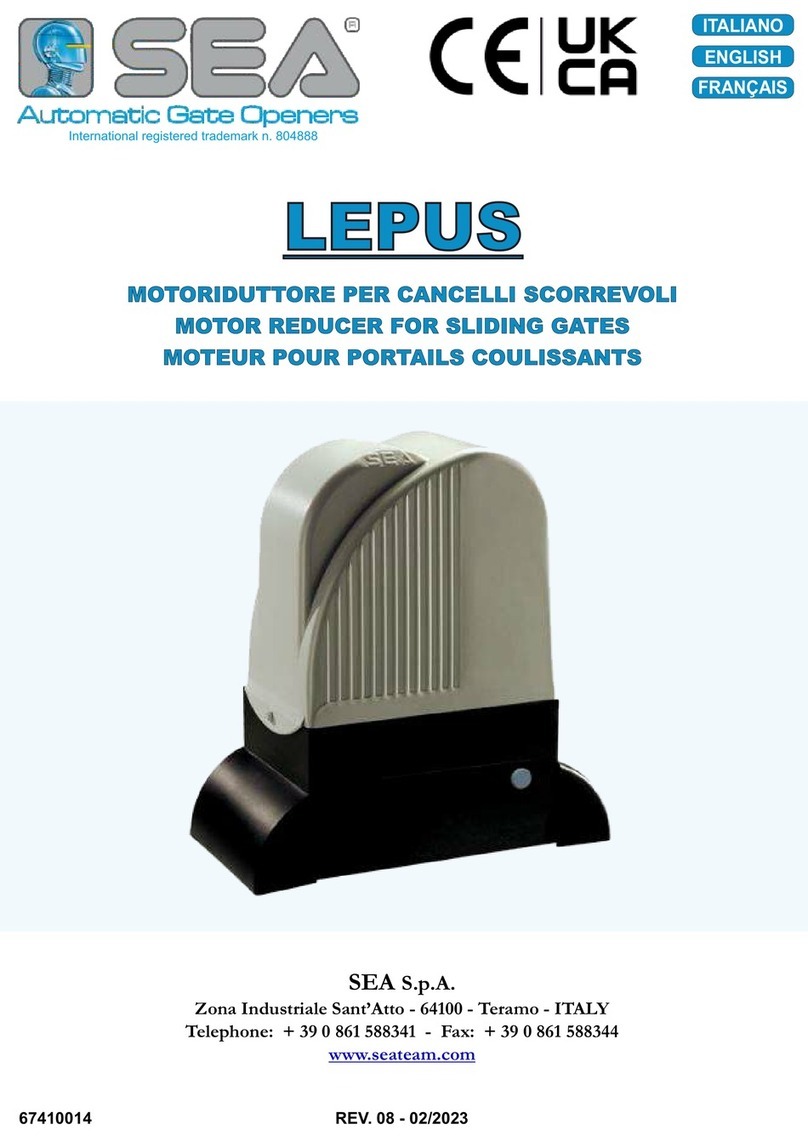

As for misunderstandings that may arise refer to your area distributor or call our help desk. These instructions are part

of the device and must be kept in a well known place. The installer shall follow the provided instructions thoroughly.

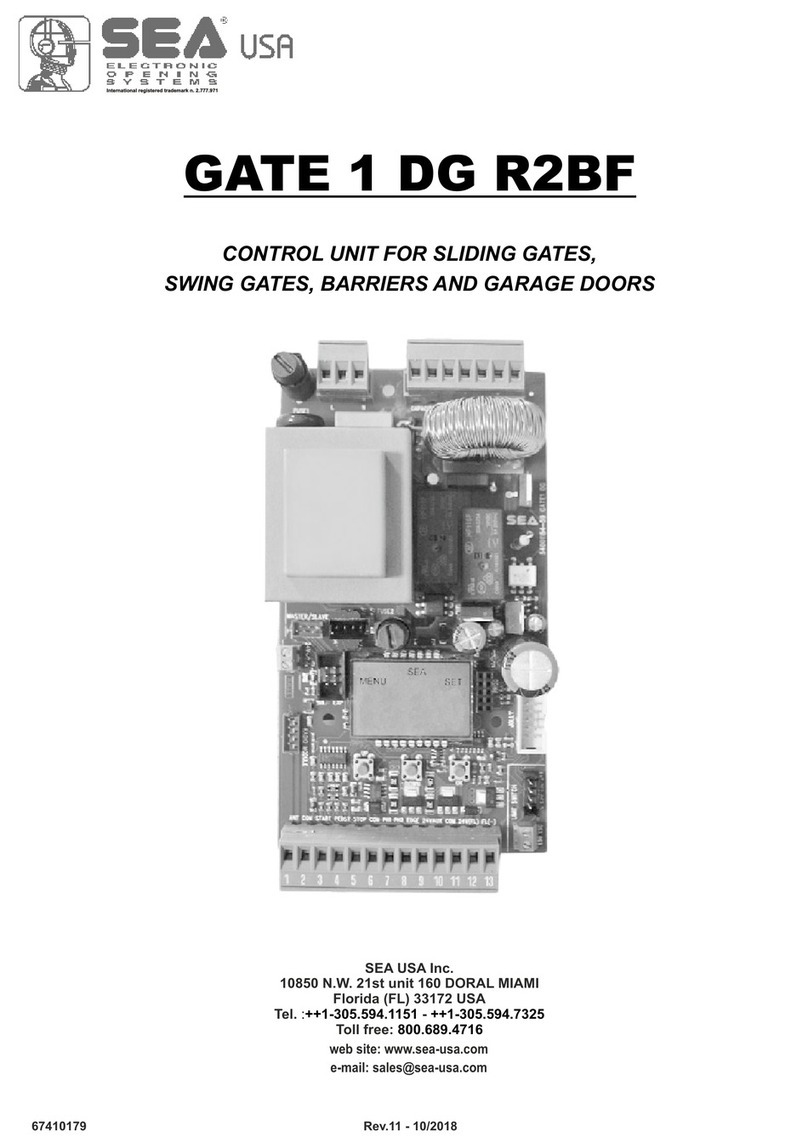

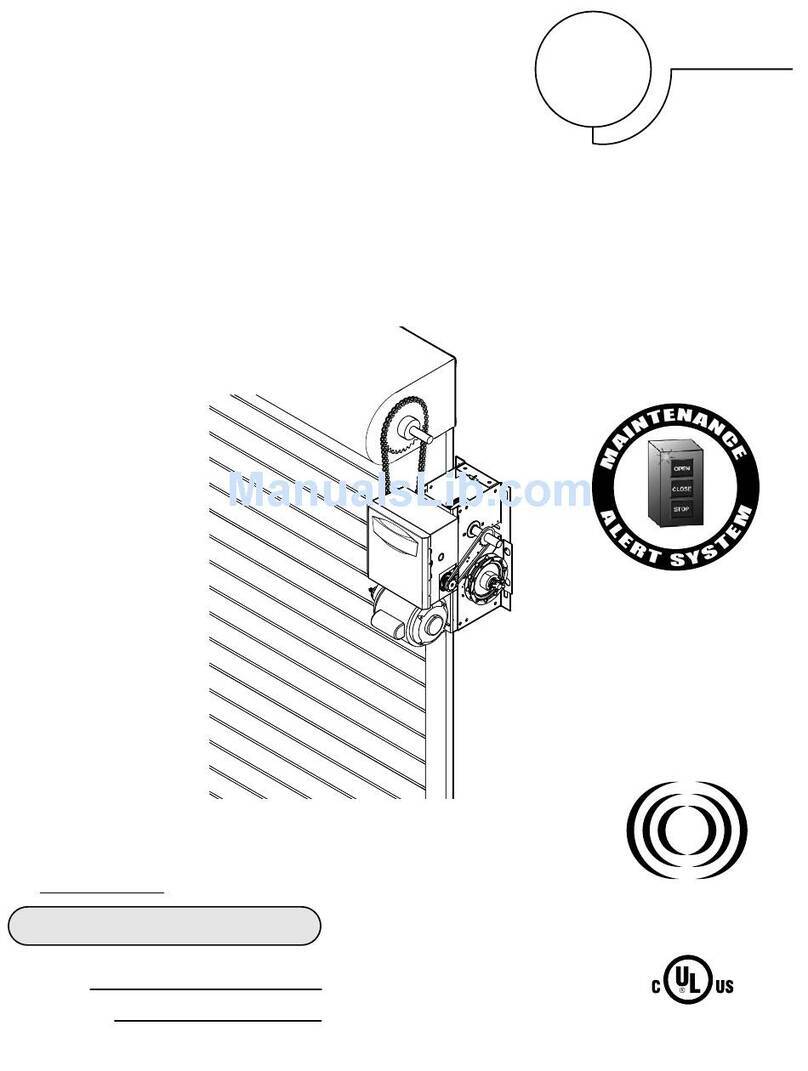

SEA products must only be used to automate doors, gates and wings. Any initiative taken without SEA USA Inc. explicit

authorization will preserve the manufacturer from whatsoever responsibility. The installer shall provide warning notices

on not assessable further risks. SEA USA Inc. in its relentless aim to improve the products, is allowed to make

whatsoever adjustment without giving notice. This doesn’t oblige SEA to up-grade the past production. SEA USA Inc.

can not be deemed responsible for any damage or accident caused by product breaking, being damages or accidents

due to a failure to comply with the instructions herein. The guarantee will be void and the manufacturer responsibility

will be nullified if SEA USA Inc. original spare parts are not being used. The electrical installation shall be carried out by

a professional technician who will release documentation as requested by the laws in force. Packaging materials such

as plastic bags, foam polystyrene, nails etc must be kept out of children’s reach as dangers may arise.

To respect the norms in force it is recommended to use the ENCODER SYSTEM together with the electronic

control units

Starting on an. 2, 206, new UL 325 changes take effect, bringing a series of new mandates for the gate operator

industry. Here’s a quick guide to the key modifications.

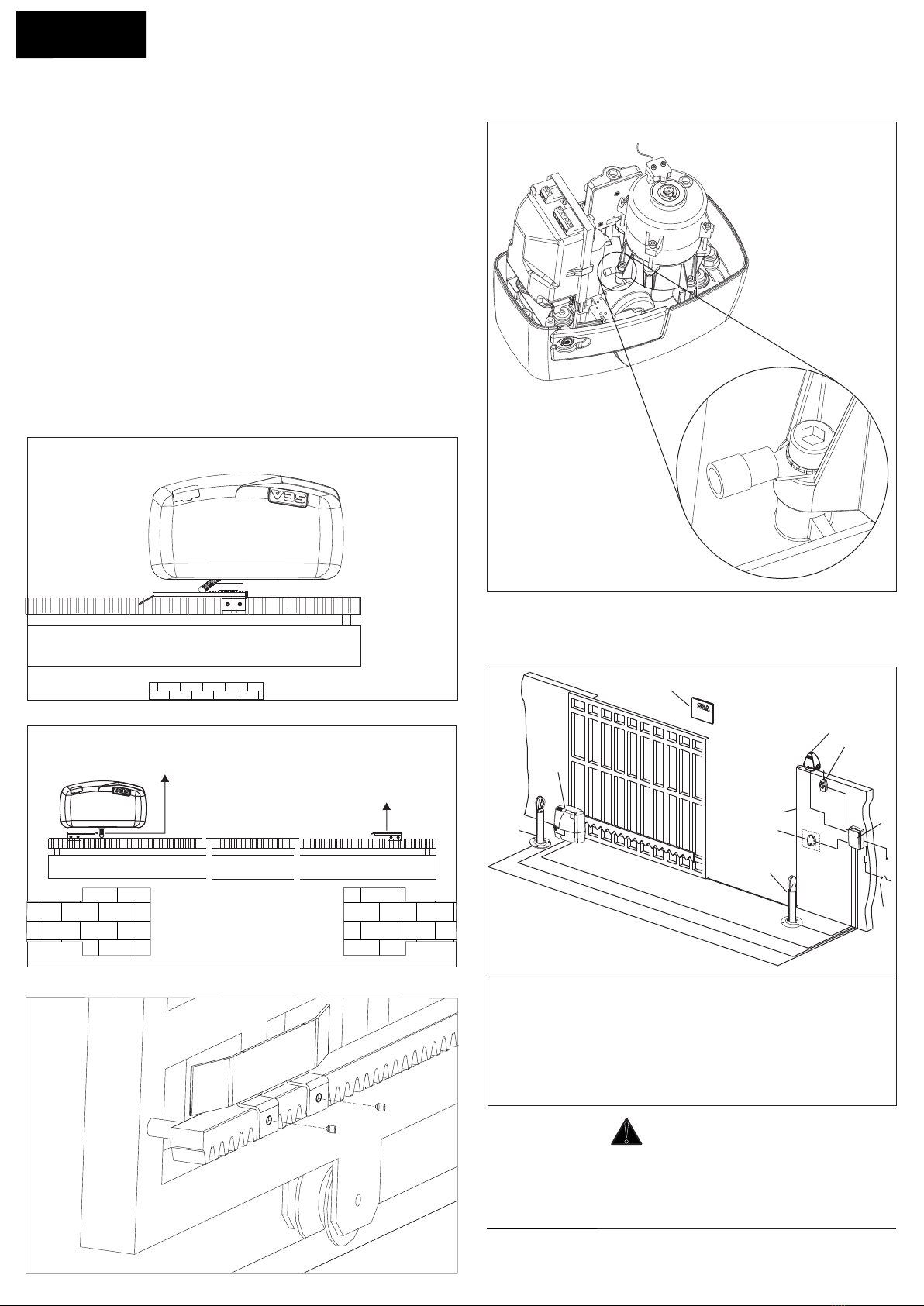

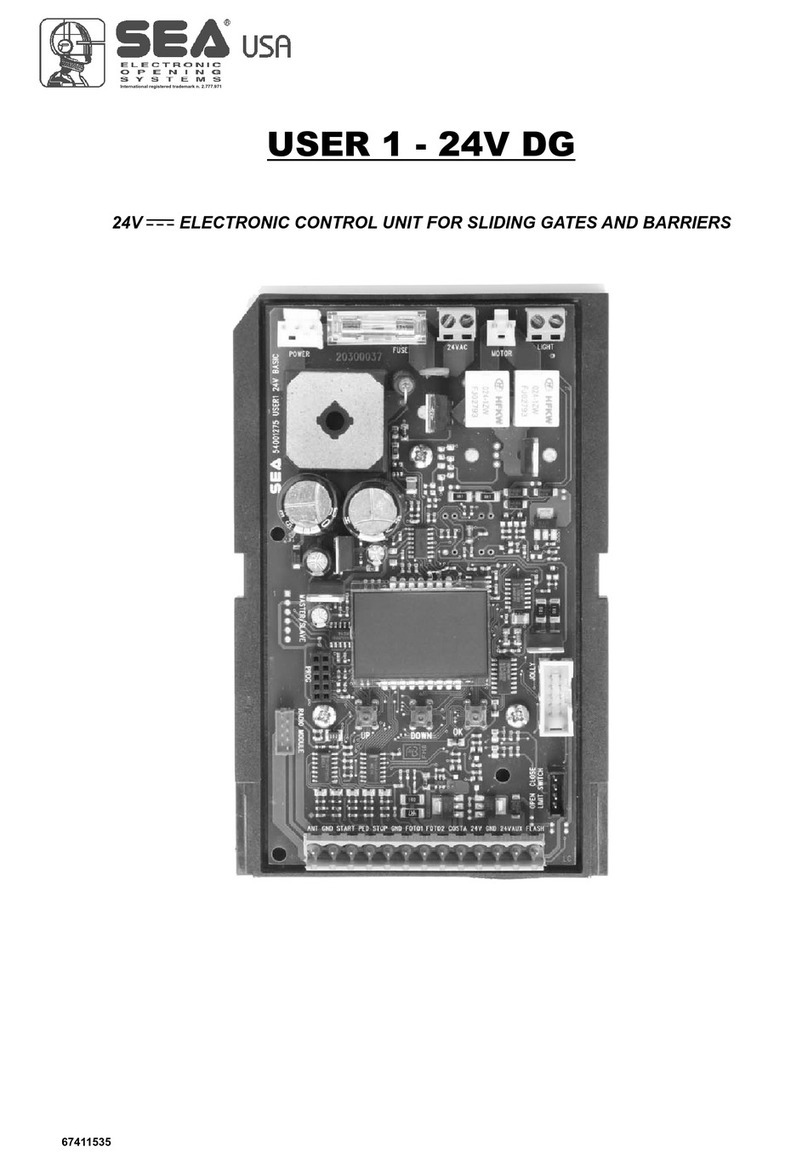

1. Entrapment-Protection Deices. ate operators are required to have a minimum of two independent means of

entrapment protection where the risk of entrapment or obstruction exists. A manufacturer can use two inherent-type

systems, two external-type systems, or an inherent and an external system to meet the requirement. However, the

same type of device cannot be used for both means of protection.

2. Monitoring Reuired. An external non-contact sensor or contact sensor may be used as a means of entrapment

protection. However, the sensor must be monitored once every cycle for the correct connection to the operator and

2 the correct operation of the sensor.

If the device is not present, not functioning, or is shorted, then the gate operator can only be operated by constant

pressure on the control device. Portable wireless controls will not function in this case.

3. Entrapment Ris Identification. As in the past, it’s up to the installer to examine the installation and determine

where a risk of entrapment or obstruction exists. Manufacturers are required to provide instructions for the placement

of external devices, but they give only examples of suggested entrapment protection in their installation manuals. If the

installer identifies a risk of entrapment or obstruction, at least two independent means of entrapment protection are

required.

4.Terminolog Change. The terms primary and secondary have been removed in the description of entrapment

protection devices. This was done to emphasize that all entrapment protection devices are equally important.

Can L ED a Oa