SEA Mercury Guide

MERCURY 400 (230V)

MERCURY 400 (110V)

MERCURY 400 (230V)

MERCURY 400 (110V)

MER. 600 (230V)

MER. 600 (110V)

MERCURY 600 (230V)

MERCURY 600 (110V)

MERCURY 400 24V (230V)

600 kg

400 kg

30%

40%

75%

MERCURY 600 24V (230V)

MER. 400 24V (230V)

MERCURY 600 24V (230V)

MERCURY 600 24V (110V) MERCURY 600 24V (110V)

MERCURY 400 24V (110V)

MER. 400 24V (110V)

MERCURY

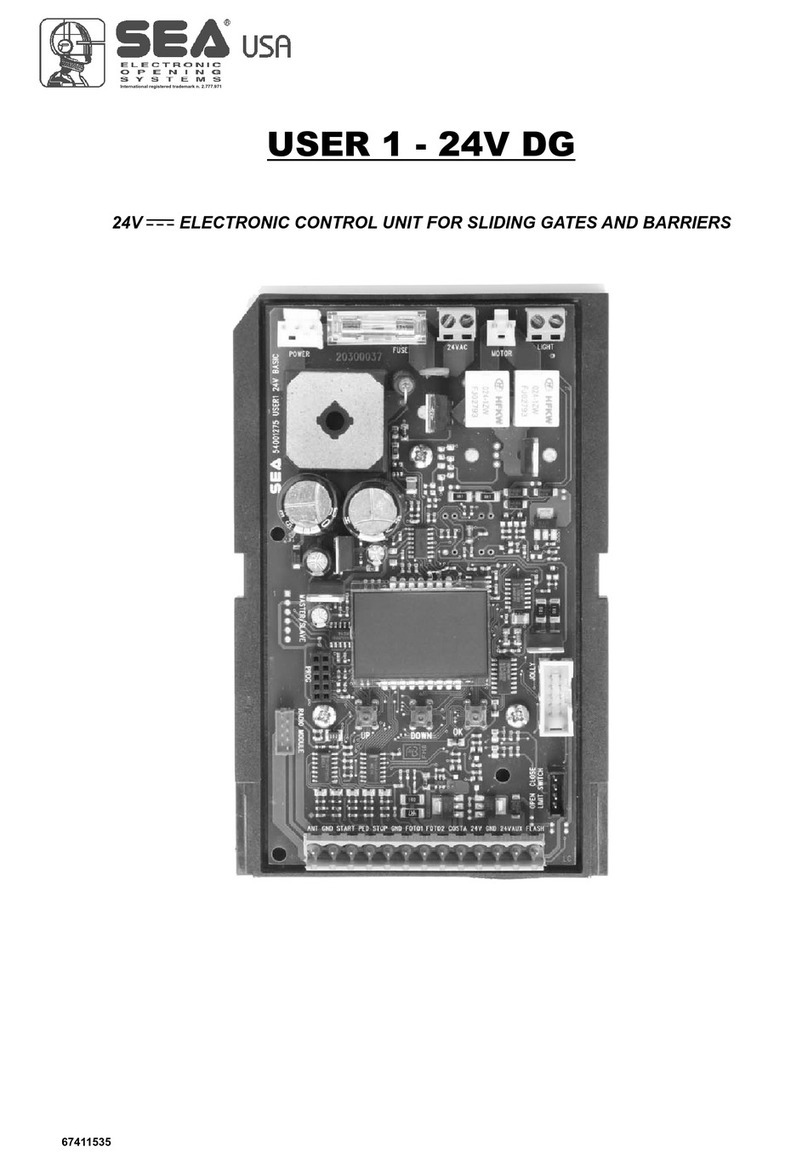

1Adjustable foundation plate

2Anchor bolts

3Pinion protection

4Pinion

5Gear release lever

6Electronic unit

7Magnetic encoder (If present)

8Micro switch (If present)

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

2

13

4

5

6

7

8

300

106

003

67411230

INSTALLATION AND CONNECTION INSTRUCTIONS

TECHNICAL DATA

Power supply

Absorbed power

Opening speed

Working frequency

Maximum torque

Working Temperature

Thermoprotection

Weight

Gate maximum weight

Anti-crushing clutch

Protection degree

Motor capacitor

Limit switch

230 V~ 50/60 Hz

320 W 80 W 110W

0.15 m/s Adjustable

40% 30% 75%

18 N m 25 N m 0/20 N m 0/30 Nm

-20°C +55°C

130°C - -

6.8 kg 7.2 kg 7.0 kg 7.5 kg

400 kg 600 kg 400 kg 600 kg

Electronic

IP 55

8 µf 10 µf - -

Mechanical

400 - 230V 600 - 230V 400 - 24V 600 - 24V

115 V~ 50/60 Hz

285 W 80 W 110W

0.15 m/s Adjustable

40% 30% 75%

18 N m 25 N m 0/20 N m 0/30 Nm

-20°C +55°C

130°C - -

6.8 kg 7.2 kg 7.0 kg 7.5 kg

400 kg 600 kg 400 kg 600 kg

Electronic

IP 55

50 µf 60 µf - -

Mechanical

400 24V-110V

600 24V-110V

400 - 110V 600 - 110V

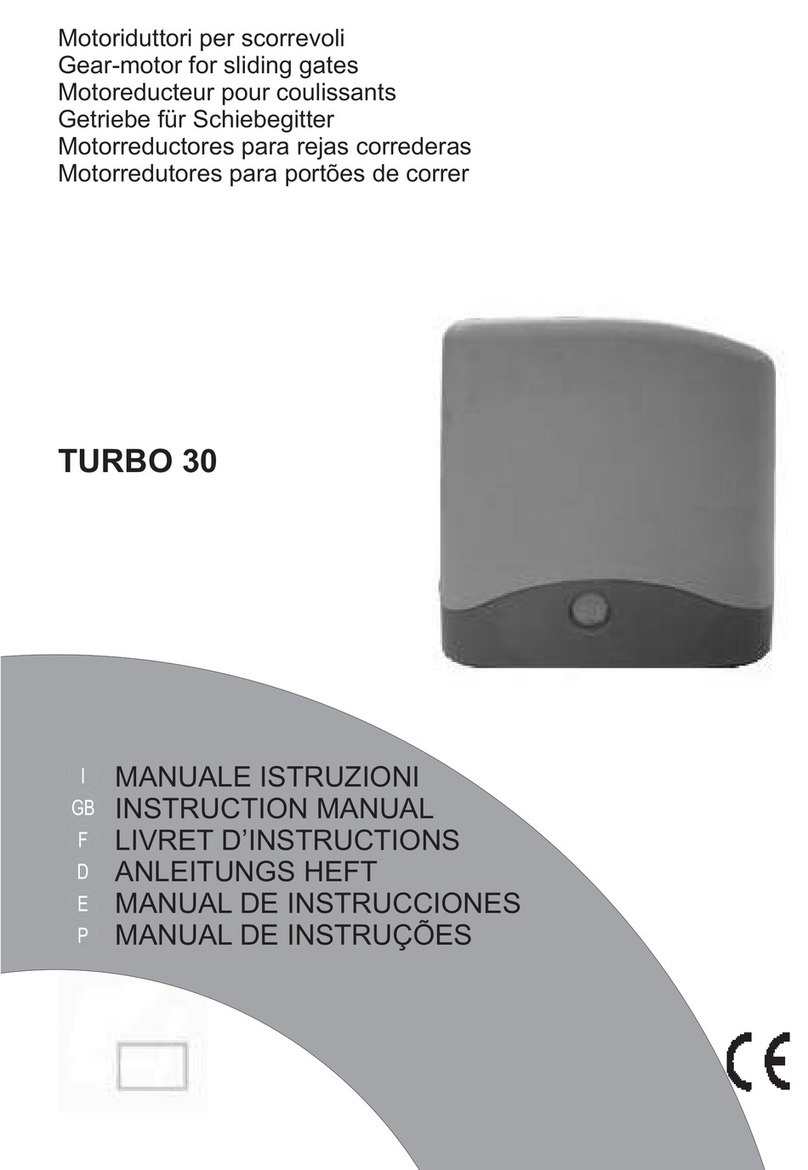

MERCURY is a sliding gate motor with grease lubricated gear.

The irreversibility of the motor grants a perfect and safe gate

closing, avoiding the need of an elecric lock. In case of electric

power cut, the lock device placed on the front part of the motor

allows the manual opening and closing of the gate. The operator

is equipped with an electronic clutch device providing the thrust

adjustment on the gate. The electronic inversion system

(optional) through encoder makes the Mercury a safe and

reliable operator in compliance with the laws in force in the

country where the product has to be installed.

MAIN PARTS

TECHNICAL DATA

Power supply

Opening speed

Working frequency

Maximum torque

Working Temperature

Thermoprotection

Weight

Gate maximum weight

Anti-crushing clutch

Protection degree

Motor capacitor

Limit switch

Absorbed power

Note: The frequency of use is valid only for the first hour at 20°C

environment temperature.

MERCURY MOTOR FREQUENCY OF USE

Gear Motor

DIMENSIONS (mm)

ENGLISH

7

Use frequency

Gate maximum weight

REV 01 - 05/2012

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

2.2. Before cementing the plate insert a flexible plastic duct of at

least 30mm in diameter into the special hole of the plate.

2.3. Before cementing the plate, make sure that it’s perfectly

leveled and that the distance of 63-68 mm as shown in Fig. 3 is

respected.

Plinth

Fig. 1

DIMENSIONS (mm)ONLY 24V VERSION

Plinth

Fig. 2

DIMENSIONS (mm)ONLY 230V VERSION

4. FITTING OF THE MOTOR

4.1. Insert the 4 grub screws into the special holes for the

adjustment of the motor height on the plate (Fig. 5).

At the end of installation check if the 4 grub screws are well

gripped on the foundation plate.

4.2. Fix the motor on the foundation plate with the 2 included

nuts, adjusting the side position (Fig. 6) so to respect the shown

quota in (Fig. 3).

1. GATE ARRANGEMENT

Before starting the installation check if all the gate parts (fixed

and mobile) have a strong and as less as possible deformable

structure, also make sure that :

a) The leaf is rigid and compact;

b) The inferior slideway is perfectly straight, horizontal and

without any obstacles which could obstruct the gate sliding;

c) The inferior sliding wheels are equipped with greasable or

water tightened bearings;

d) The superior slideway has been produced and placed in the

manner that the gate is in a perfect vertical position;

e) Mechanical stops are always installed in order to avoid

possible derailment of the leaf.

2. FOUNDATION PLATE ANCHORING

For the installation of the foundation plate you have to:

2.1. Prepare a concret basement with the dimensions shown in

Fig. 1 (only Mercury 24V) and Fig. 2 (only Mercury 230V) where

the foundation plate and the anchoring bolts will be cemented.

NOTE: It is recommended (gate structure permitting) to lift the

foundation plate about 50 mm from the ground, in order to avoid

eventual water stagnation.

Fig. 4

67411230

3. CABLES PASSAGE ARRANGEMENT

Mercury is provided with seven holes for electric cables

passage.

Important:Always run mains carrying cables (230V ~) inseparate

holes to low voltage cables ( 24V) Fig. 4.

ENGLISH

8

150

04 2

250

150

420

250

Fig. 3

Z16

Z20

100 mm

108 mm

62 mm

63-68 mm

MINIMUN DIMENSION Q

Fig. 5

77

77

REV 01 - 05/2012

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

5.4. Make sure that all the gear rack elements are perfectly

aligned and placed correctly (teeth in phase). It’s suggested to

place two aligned elements in front of a third one as shown in

Fig.10;

5.5. Repeat the above described operation for all the remaining

gear rack elements which have to be installed;

5.6. To avoid that the door weights down on the pinion (Fig.11)

lift up the whole rack about 1,5 mm.

Warning: Keep a gap of about 0,5 mm between pinion tooth

and gear rack tooth;

5.7. Make sure that the gear rack works at the center of the

pinion along all rack elements, if necessary, adjust the length of

the spacers.

Fig. 9

5. GEAR RACK MOUNTING

5.1. Release the motor and open the leaf completely;

5.2. Fix on each gear rack element the support pawls with the

appropriate lock screws, make sure to put them in the upper part

of the hole (Fig. 7) ;

5.3. Lean the gear rack element on the toothed pinion of the

motor in parallel to the ground slideway of the gate, as shown in

Fig. 8 and electrically weld the central pawl B to the gate

structure (Fig. 9).

Manually move the gate until pawl C is placed corresponding to

the pinion and fix it through electric welding. Repeat the same

procedure for pawlA after having placed it corresponding to the

pinion;

Fig. 10

1,5 mm

Fig. 11

6. LIMIT SWITCH ADJUSTMENT

6.1. To install and adjust the limit switches in opening procede as

follows (Fig. 12):

- Completely open the gate.

- Place the plate on the rack in order to have the lever of the

mechanical limit switch (Fig. 13) at the point X that is 50 mm from

the bent side of the plate and fix it with the delivered screws (Fig.

14).

Fig. 6

67411230

ENGLISH

9

Fig. 7

Steel rack

(to weld)

Plastic rack,

steel core

(to screw)

Fig. 8

ABC

REV 01 - 05/2012

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 14

7. GROUNDING (Fig. 15 - Fig. 16)

Fig. 15

6.2. To install and adjust the limit switches in closing the gate

must be completely closed.

8. ELECTRIC CONNECTIONS OF THE

INSTALLATION (Fig. 17)

2x ,51

2x1,5

3x1,5

1x ,1 5

52 1 x ,

x3 1,5

13 x , 5

6x1,5

8x1,5

1

2

3

4

10

5

6

7

8

9

Fig. 17

Example: Mercury 230V

Fig. 12

67411230

Limit switch in closing

Limit switch in opening

Mechanical limit switch

Setting the trimmer for braking on the electronic control unit, it is

possible to make the gate stop on the desired position.

1) Mercury

2) Photocell Sx

3) Photocell Dx

4) Mechanical safety edge

8) Warning notice

9) Junction box

10) Differential 16A - 30mA

5) Key push botton

6) Flasher

7) Receiver

2

The cable mesures are indicated in mm

ENGLISH

Fig. 13

10

Fig. 16

Example: Mercury 24V

REV 01 - 05/2012

Annual

Annual

Annual

Annual

Annual

Annual

Annual

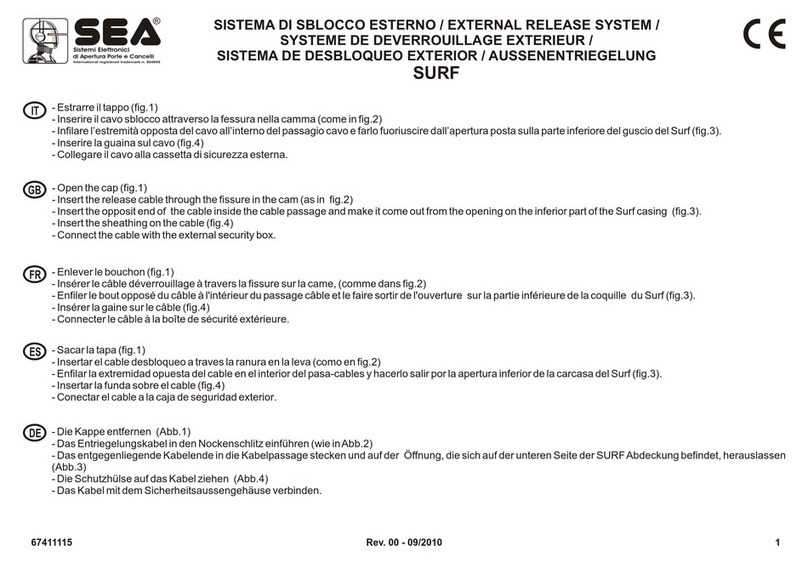

9. RELEASE SYSTEM

9.1. To release procede as follows:

- Insert the key, push and turn about 90° clockwise (Fig. 18).

- Pull the release lever until it stops, about 90° ( Fig. 19).

Note: when pulling the release lever the electronic control

unit receives a stop impulse through the micro-switch

placed on the inside (if present).

9.2. To relock procede as follows:

- Push the release lever to complete closing.

- Rotate the key counter-clockwise and extract it.

Once the lock has been restored the electronic control unit is

reactivated (only if a micro-switch is mounted) .

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 20

67411230

Page for both instaler and user

10. RISK EXAMINATION

The points pointed by arrows in Fig. 20 are potentially

dangerous. The installer must take a thorough risk examination

to prevent crushing, conveying, cutting, grappling, trapping so

as to guarantee a safe installation for people, things and animals

(

)

Re. Laws in force in the country where the installation has been

made.

NOTICE

SEA s.r.l can not be deemed responsible for any damage or

accident caused by product breaking, being damages or

accidents due to a failure to comply with the instructions herein.

The guarantee will be void and the manufacturer responsibility

(according to Machine Law) will be nullified if SEA Srl original

spare parts are not being used.

This is a quotation from the GENERAL

DIRECTIONS that the installer must read carefully before

installing and hand over to the final user. Packaging materials

such as plastic bags, foam polystyrene, nails etc must be kept

out of children’s reach as dangers may arise.

The electrical installation shall be carried out by a professional

technician who will release documentation as requested by the

laws in force.

SAFETY PRECAUTIONS:

All electrical work and the choice of the operating logic should

conform to current regulations. A 16 A 0,030 A differential

switch must be incorporated into the source of the operators

main electrical supply and the entire system properly earth

bonded. Always run mains carrying cables in separate ducts to

low voltage control cables to prevent mains interference.

SPARE PARTS:

To obtain spare parts contact:

SEA s.r.l. -Zona Ind.le, 64020 S. ATTO Teramo Italia

SAFETYAND ENVIRONMENTAL COMPATIBILITY:

Don’t waste product packing materials and/or circuits.

When being transported this product must be properly packaged

and handled with care.

SEA reserves the right to do changes or variations that may be

necessary to its products with no obligation to notice.

Check the

Check the release functionality

Check the distance between pinion and gear rack (1.5 mm)

Check the usury status of pinion and gear rack

Check the fixing screws

Check the connection cables integrity

Check limit switch functionality and status in opening and

closing and the related small plates

efficiency of the electronic anti-crushing clutch

All the above described operations must be done exclusively by

an authorized installer.

PERIODIC MAINTENANCE

ENGLISH

11

Fig. 18

Cosl e

eO p n

Push and

turn

Fig. 19

REV 01 - 05/2012

SELF INSTALL - NEED TECHNICAL

ASSISTANCE?

OPTION 1: DIRECT WITH THE SERVICE DESK – QUICKEST AND MOST EFFECTIVE METHOD

Submit your enquiry direct with the service desk at – service@automaticsolutions.com.au

The service desk has the most experienced staff in Australia to help with your problem but they need your help.

Describe your problem in detail and as clearly as possible. Don’t forget to include a telephone number.

Be certain to detail which model or models of you are working with.

Send photos of the installation – they love photos. The people at the service desk are good but they are

even better when they can see the installation. Send photos of the overall scene so they can see the

entire installation. Also send photos of the wiring to the control board and any other part of the

installation you think is relevant.

Send video if appropriate. Smartphone’s these days take remarkably good video in small file sizes which

can be emailed in a moment. If your problem needs a video to show the issue please feel free to send it.

NOTE: THIS IS BY FAR THE FASTEST AND MOST SUCCESFUL WAY TO SOLVE YOUR PROBLEM

PHOTOS AND VIDEOS ARE THE NEXT BEST THING TO BEING THERE

OPTION 2: LODGE YOUR ENQUIRY LOCALLY - SLOWER BUT CAN STILL BE EFFECTIVE

Make contact with the store of purchase. Branch staffs are typically not technicians and dependent on their length

of service will have varying degrees of technical knowledge. If they cannot help however they will certainly either

source help locally from their technicians or make contact with the service technicians on your behalf.

OPTION 3: SERVICE CALL WITH AUTOMATIC SOLUTIONS TECHNICIAN – SLOWEST METHOD

If you fall within the local branch service area it may be possible to book a local technician to look at your

installation. Wait times will vary dependent on local workloads. The cost is a service fee which includes the first

half hour and the hourly rate thereafter. If any Automatic Solutions provided parts are found to be defective and

within warranty these will be provided free of charge.

(NOTE: If you suspect that any parts are defective and within warranty you may wish to consider option 4)

A note on this option: If you decide on this option you will be asked to sign an “authorisation to proceed” which

will provide legal authority and payment security. This form has three options available of which only the first two

are available to you. The third option is for warranty repairs only for full install customers. Self install customers

requiring warranty only service need to refer to option four below.

IMPORTANT: IN SHORT THIS OPTION WILL INCUR CHARGES

OPTION 4: RETURN THE PRODUCT IF BELIEVED TO BE FAULTY

As a self install customer who has purchased product if you believe the product to be faulty rather than an

installation or site problem you have the option of returning the product for evaluation and to exercise your right

to a replacement, repair or refund as applicable. All returned product is forwarded immediately to the service

technicians for evaluation and response. There are two main methods available to return product –

Direct to the service centre – this is the quickest method as it cuts out the branch delay

Via the branch of purchase – slower because of the delay at the branch

When choosing this option you need to complete a product return form. This form gives you all the information

on procedure involved and where to send to. These are available at the branch of purchase, can be emailed to

you (contact your branch), or available here - http://automaticsolutions.com.au/page/warranty.php

Table of contents

Other SEA Garage Door Opener manuals

SEA

SEA B 100 PLUS 1000N User manual

SEA

SEA SURF Series User manual

SEA

SEA LEPUS 800 Instruction manual

SEA

SEA USER 1 - 24V DG R1B User manual

SEA

SEA TAURUS RACK Series User manual

SEA

SEA Compact 400 Instruction manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA STAR 500 User manual

SEA

SEA FLIPPER Instruction manual

SEA

SEA LEPUS 600 User manual