For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Products.

4. OPERATING INSTRUCTIONS

NOTE: The crane MUST be kept clean and dry and must be maintained in accordance with these instructions.

5.1. Lubrication

5.1.1. Oil all working parts monthly.

5.1.2. The ram is filled with oil and should only require occasional topping up. For the occasional top up DO NOT use brake fluid, as this

will damage the hydraulic seals. Proceed as follows:

a) Use only good quality hydraulic jack oil available from your supplier.

b) DO NOT OVERFILL as this will cause failure.

c) After filling with hydraulic oil, pump the crane up to full height and pour off any excess oil.

5.2. Inspection of crane before use

5.2.1. Before each use of the crane you must make a visual inspection for leaks, damage, loose or missing parts.

5.2.2. The workshop crane must be inspected immediately if it has been subject to an abnormal load or shock. It is recommended that

such an inspection is made by an authorised service agent.

5.2.3. The owner and/or operator must be aware that repair of this equipment will require specialised knowledge and facilities.

It is recommended that an annual inspection of the workshop crane is made by an authorised service agent.

5.3. Storage

Always store the crane fully closed so that the jib is in lowest position and the ram is closed.

5. MAINTENANCE

The owner and/or operator shall study these instructions and retain them for future use.

6.1. Understanding instructions and warnings.

The owner and/or operator shall understand the operating instructions and warnings before operating the crane. Warning information

must be emphasised and understood. If the operator is not fluent in English, the product instructions and warnings must be read to, and

discussed with, the operator in the operator’s native language by the owner, making sure the operator understands the contents.

6.2. Damaged Cranes.

Any crane which appears to be damaged, badly worn, or operates abnormally MUST BE REMOVED FROM SERVICE! It is recommended

that necessary repairs be made by an authorised service agent.

6.3. End of service

Through years of normal wear, the crane will eventually become unserviceable. When this happens ensure the hydraulic oil is drained

off and disposed of in accordance with local authority regulations.

6.4. Test Certificate.

According to requirements of the UK Health and Safety Executive, a test certificate is packed with this crane. The test certificate is valid

for one year from the date of first placing the crane into use. Your insurance company will want to have a copy of the test certificate for

their file. Additional copies of the test certificate can be purchased within one year of the date of purchase. If you need a copy please

ask your supplier. After one year your insurance company has the right to request a re-test of the crane. This is a chargeable service

and can be obtained by contacting companies listed under “Lifting Gear” in Yellow Pages.

6. OWNER’S & OPERATOR’S RESPONSIBILITIES

CRANE GUARANTEE

Your crane is guaranteed for one year from the date of purchase. The Guarantee does not cover faults caused by incorrect use, lack of

maintenance, accidental damage or damage caused to third parties through misuse. You are recommended to inform your insurers and check

that adequate cover is in place. Warranty claims must be supported by a copy of the dated purchase receipt.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Signed by Mark Sweetman 20th November 2000

SC10

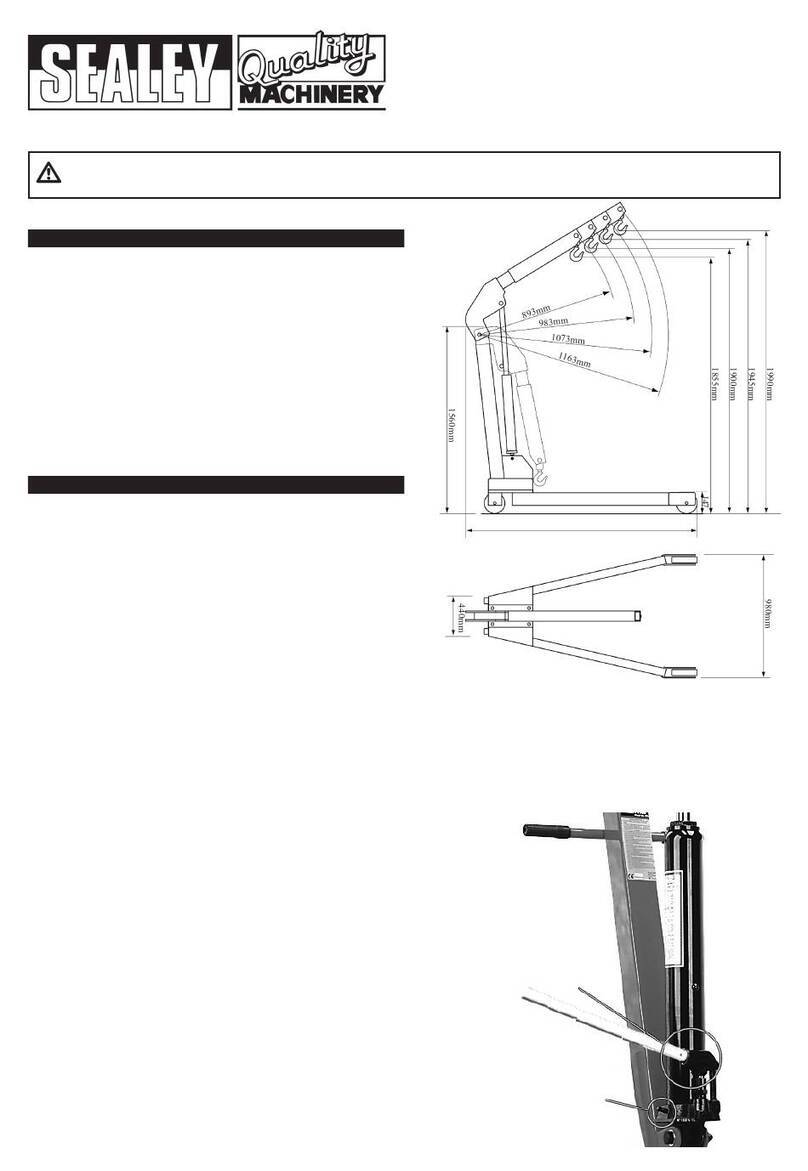

4.1. Using the pumping handle end, turn the release valve firmly to the right.

4.2. Put handle into pump socket and pump. The jib will move, continue to pump until the jib reaches the height at which the load can be secured.

4.3. Connect the crane hook to the load using a suitable certified sling or support beam. Ensure you are aware of the load weight,

and check that it is within the capacity of the crane (at the jib extension you are using) and the sling or support beam. When removing

engines ensure you know the weight to be lifted. Use only the lifting points recommended by the vehicle manufacturer.

4.4. Lift only from directly above the load. WARNING! DO NOT lIfT ThE lOAD AT AN ANGlE!

4.5. To lower load, position handle on release valve at base of ram and turn VERY SLOWLY anti-clockwise avoiding any sudden movement.

WARNING! Do not allow the load to drop suddenly.

4.6. The crane is not a transportation device but may be used to reposition the load being worked on. To do so, lower load and jib

with care, to the lowest possible point before attempting to move. Do not try to move crane in a sideways direction. The crane is

not designed to support the load indefinitely. When you have repositioned the load, lower the load onto a secure and

appropriate working base, being fully aware of your own and other persons locations in relation to the lowering load.

4.7. When load has been secured, remove lifting sling, support beam etc. and place crane in a safe location with lifting beam fully lowered.

SC10 - 0016 - (1) - 161100

NOTE: ENSURE YOU hAVE READ AND UNDERSTOOD ThE SAfETY INSTRUCTIONS

IN SECTION 1 BEfORE YOU OPERATE ThE CRANE.

Declaration of Conformity We, the sole importer into the UK, declare that the product listed below is in conformity

with the following standards and directives.

Folding Workshop Crane. Model No: SC10

98/37/EC Docks Regulations 1934, 18a 22a EN292-2

Model No:

Serial No:

Batch No:

The construction file for this product is held by the Manufacturer and may be

inspected, by a national authority, upon request to Jack Sealey Ltd.

01284 757500 E-mail: sales@sealey.co.uk

01284 703534

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.