INDUSTRIAL HYDRAULIC PIPE BENDERS WITH

STAND 9TONNE / 15TONNE

MODELS NO: PBS90.V2, PBS91.V4

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Ensure the pipe bender is in sound condition and good working order. Take action for immediate repair or replacement of damaged

parts. Use recommended parts only. The use of improper parts may be dangerous and will invalidate the warranty.

9Keep pipe bender and associated parts clean for best and safest performance.

9Locate the pipe bender in a suitable, well lit working area.

9Keep working area clean, tidy and free from unrelated materials.

9Use on level and solid ground, preferably concrete.

9Ensure all non-essential persons keep a safe distance whilst the pipe bender is in use.

9Wear appropriate safety equipment, including eye protection, ear protection, protective gloves and safety footwear.

WARNING! Cut pipe edges may be sharp, take care when handling any cut steelwork.

9Check that bending die is correctly seated on ram and that the roller shafts are fully engaged in the frame and pinned before operating hydraulic unit.

9Keep hands away from die and rollers when bending pipe.

9Use a qualified person to lubricate and maintain the hydraulic unit.

9Confirm that the recommended hydraulic oil is used during maintenance.

8DO NOT top up system with brake fluid. Use hydraulic oil only.

8DO NOT operate the pipe bender if damaged.

8DO NOT allow untrained persons to operate the pipe bender.

8DO NOT exceed the rated capacity of the hydraulic unit (see Section 3).

8DO NOT use the pipe bender for purposes other than that for which it is intended.

8DO NOT alter the pressure control valve.

9When not in use, store pipe bender, with the hydraulic ram in the down position, in a dry, childproof area.

When using hydraulic type pipe benders, the bent pipe or tube is prone to deformation on both the inside and

outside curvature.

The pipe or tube can be deformed into an oval shape or creased depending on the wall thickness of the material.

This is not a fault and largely unavoidable. Consider packing the pipe or tube with dried sand or similar medium

before bending as this may help to alleviate deformation of the pipe or tube. Pack the sand tight and cap both ends.

2. INTRODUCTION

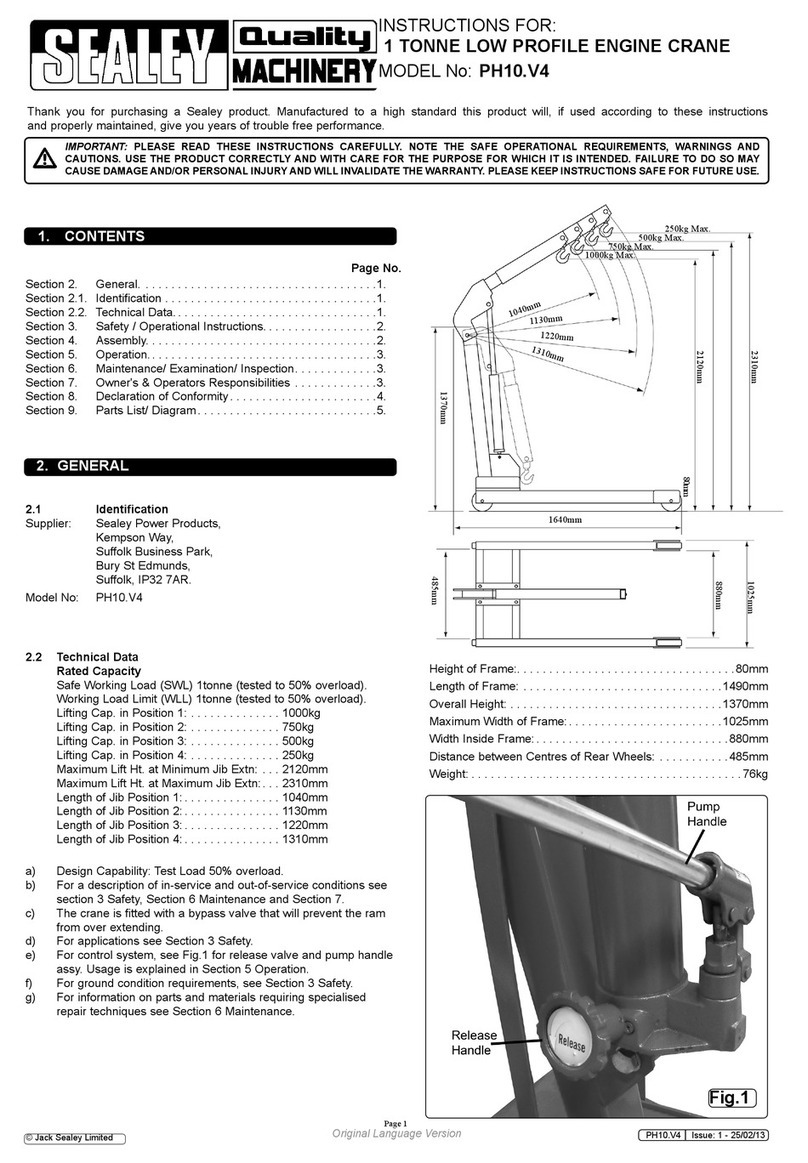

PBS91.V4

Tripod mounted pipe bender suitable for bending pipes up to 180°. Integral 15tonne ram. Suitable for bending DIN classified medium and heavy pipe.

2-Speed hydraulic pump gives fast pipe positioning and the power to bend 75mm pipe. Supplied with eight (15mm(1/2”) - 75mm(3”) interchangeable

pipe dies and packed in a heavy wooden crate for easy transportation.

PBS90.V2

Tripod mounted pipe bender suitable for bending pipes up to 180°. Integral 9tonne ram. Suitable for bending DIN classified medium and heavy pipe.

2-Speed hydraulic pump gives fast pipe positioning and the power to bend 50mm pipe. Supplied with six (15mm(1/2”) - 50mm(2”)) interchangeable

dies. Packed in a heavy wooden crate for easy transportation.

3. SPECIFICATION

Refer to

instruction

manual

Wear eye

protection Wear ear

protection Wear protective

gloves Wear safety

footwear Warning!

PBS90.V2, PBS91.V4 Issue:3 (2,H,F) 04/08/22

Original Language Version

© Jack Sealey Limited

PBS90.V2 PBS91.V4

Die Sizes: 15mm(1/2”), 20mm(3/4”), 25mm(1”), 32mm(1-1/4”),

40mm(1-1/2”), 50mm(2”) 15mm(1/2”), 20mm(3/4”), 25mm(1”), 32mm(1-1/4”),

40mm(1-1/2”), 50mm(2”), 63mm(2-1/2”), 75mm(3”)

Height: 700mm 700mm

Maximum Load: 9tonne 15tonne

Maximum Pipe Diameter: 50mm 75mm