Thank you for purchasing a Sealey Product. Manufactured to a high

standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

ENGINE SUPPORT BEAM

500kg CAPACITY, DOUBLE SUPPORT

MODEL No: ES502.V2

Ensure that the engine support is in good working order. Take action for

immediate repair or replacement of damaged parts. Use genuine parts

only. The use of unauthorised parts may be dangerous and will invalidate

the warranty.

Locate the vehicle in a suitable, well lit work area.

Keep work area clean and tidy and free from unrelated materials.

Ensure the vehicle handbrake is engaged and the engine/motor is

switched off.

Ensure all non-essential persons keep a safe distance whilst the engine

support is in use.

DO NOT use the engine support if damaged.

DO NOT allow untrained persons to operate the engine support.

DO NOT use the engine support for purposes other than that for which it

is designed.

DO NOT exceed the rated capacity of the engine support.

When not in use, store engine support in a safe, dry, childproof area.

2. INTRODUCTION & SPECIFICATION

4. OPERATION

3. ASSEMBLY INSTRUCTIONS

1. SAFETY INSTRUCTIONS

2.1. Designed to support and accurately position engines during maintenance

operations such as replacing anti-vibration mountings and certain body

panels. Also used as an aid for the removal of gearboxes and

transmissions. Beam supported on rubber feet and fine adjustment

control is obtained by using double screw/hook mechanisms. Supplied

with two short lengths of chain.

2.2. Maximum Capacity ...................................... 500kg

Maximum Width ...................................... 1605mm

Minimum Width ........................................ 605mm

Screw Travel .......................................... 260mm

Weight...............................................13.96kg

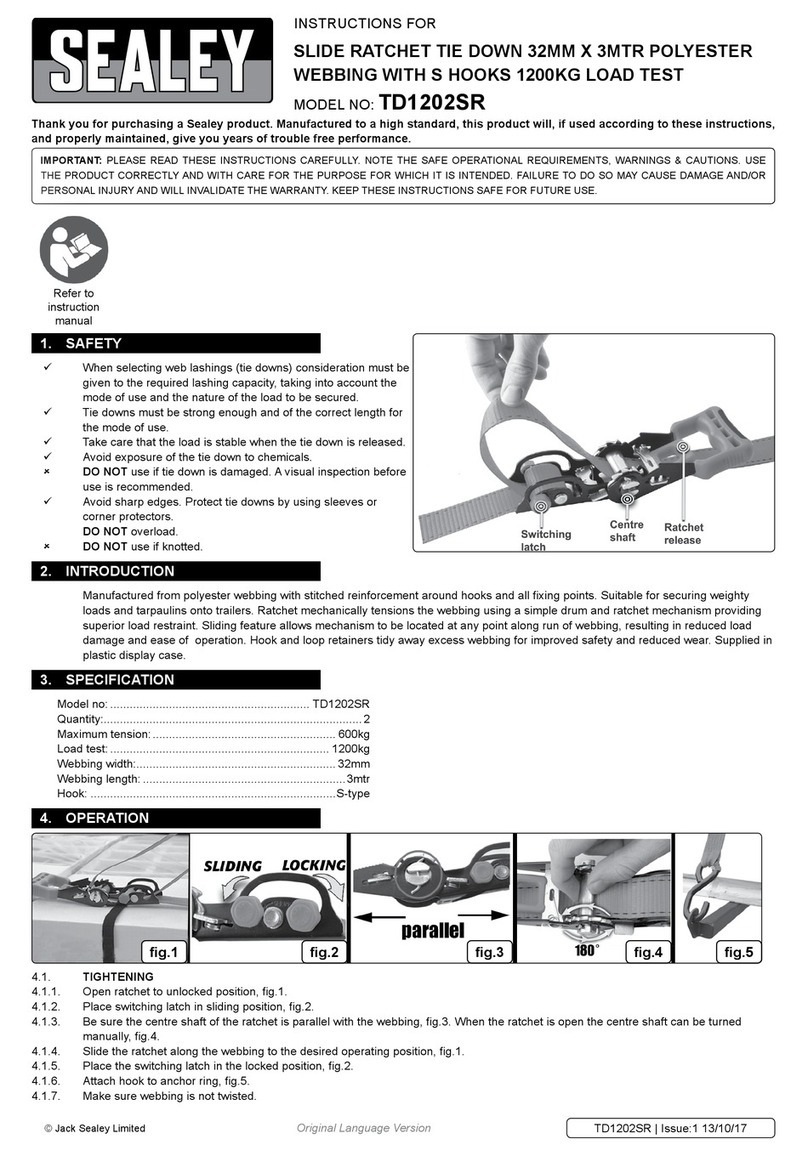

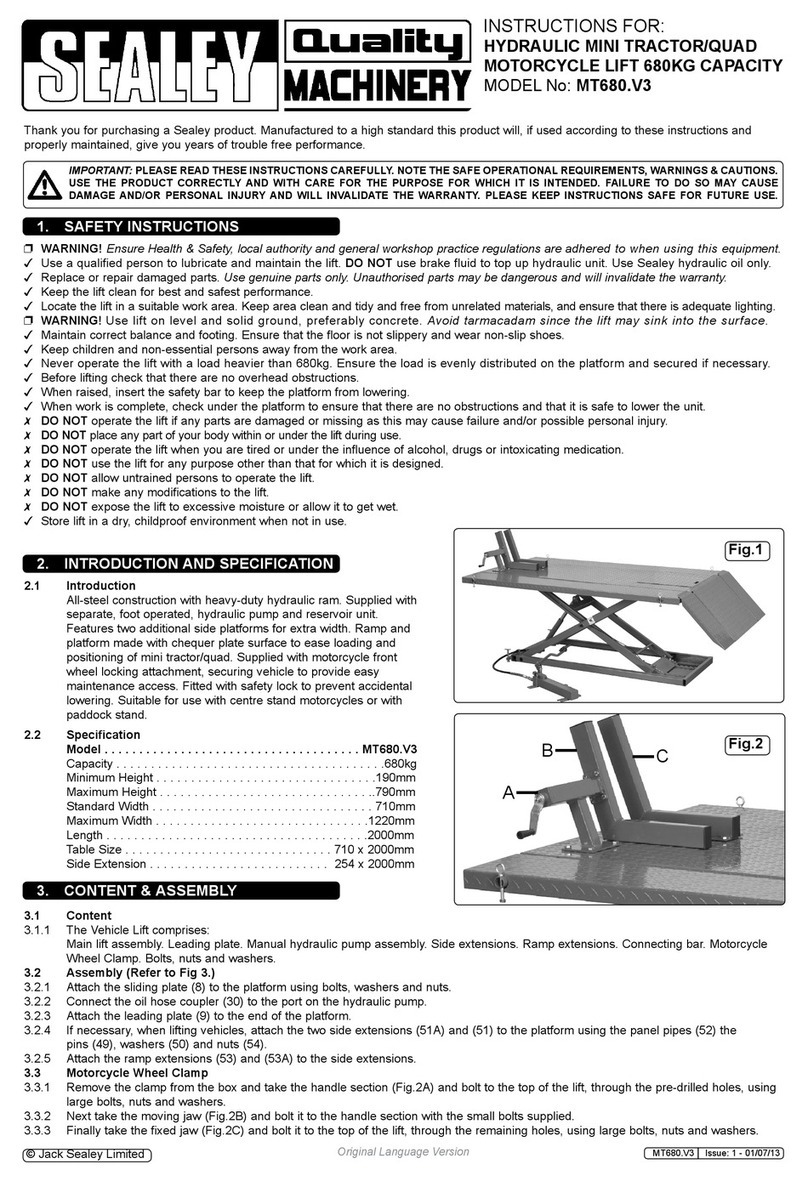

(4) and insert the rod through the slot in the main support guide from

underneath. Place a large washer (7) over the thread on top of the rod

and secure the assembly to the main support guide by screwing on a grip

knob (6) as shown in fig.1. Assemble the other foot/standing block and fix

the assembly to the other end of the main guide beam in the same way.

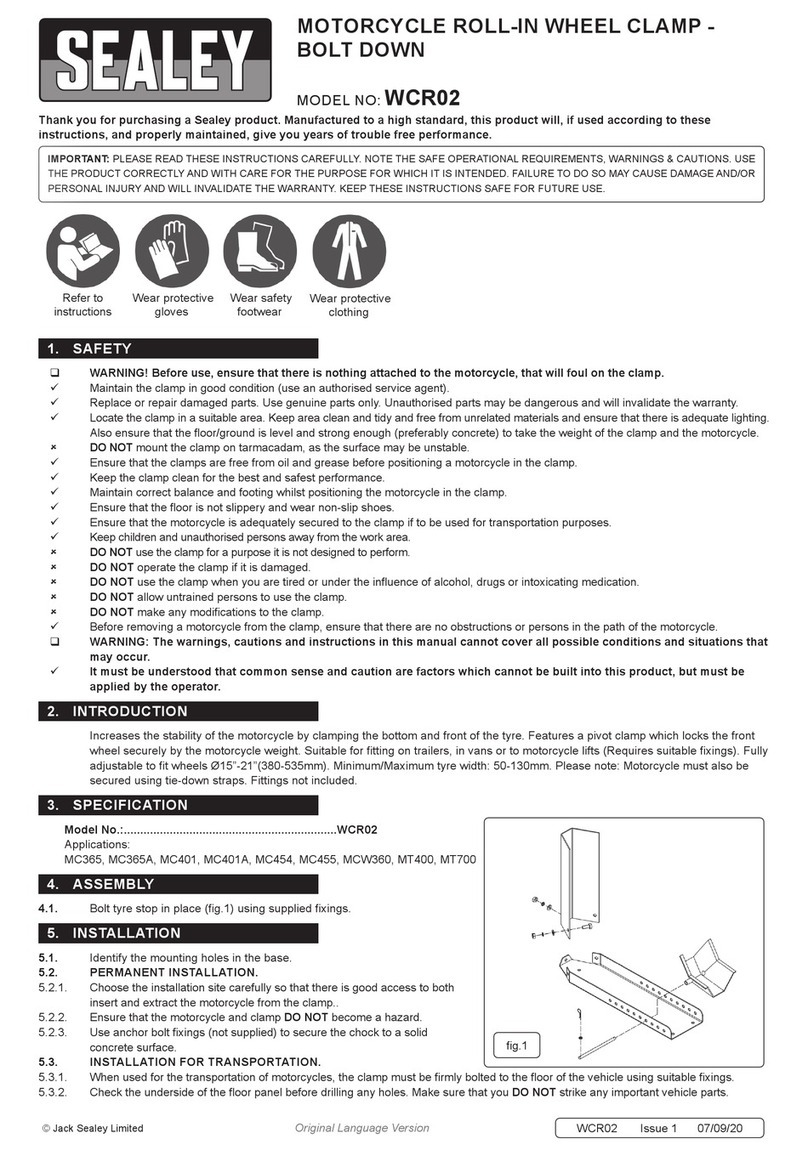

3.3. Drop a large washer (8) over adjustable screw (3) and screw lift

handle (2) onto the top of the adjustable screw. Screw the lift handle

approximately half way down the threads. Make up the second

adjustable screw in the same way and have both assemblies ready to

drop through the slot in the main guide beam after the beam has been

placed over the engine bay.

3.4. The chains should also be attached when the guide beam is mounted

over the engine.

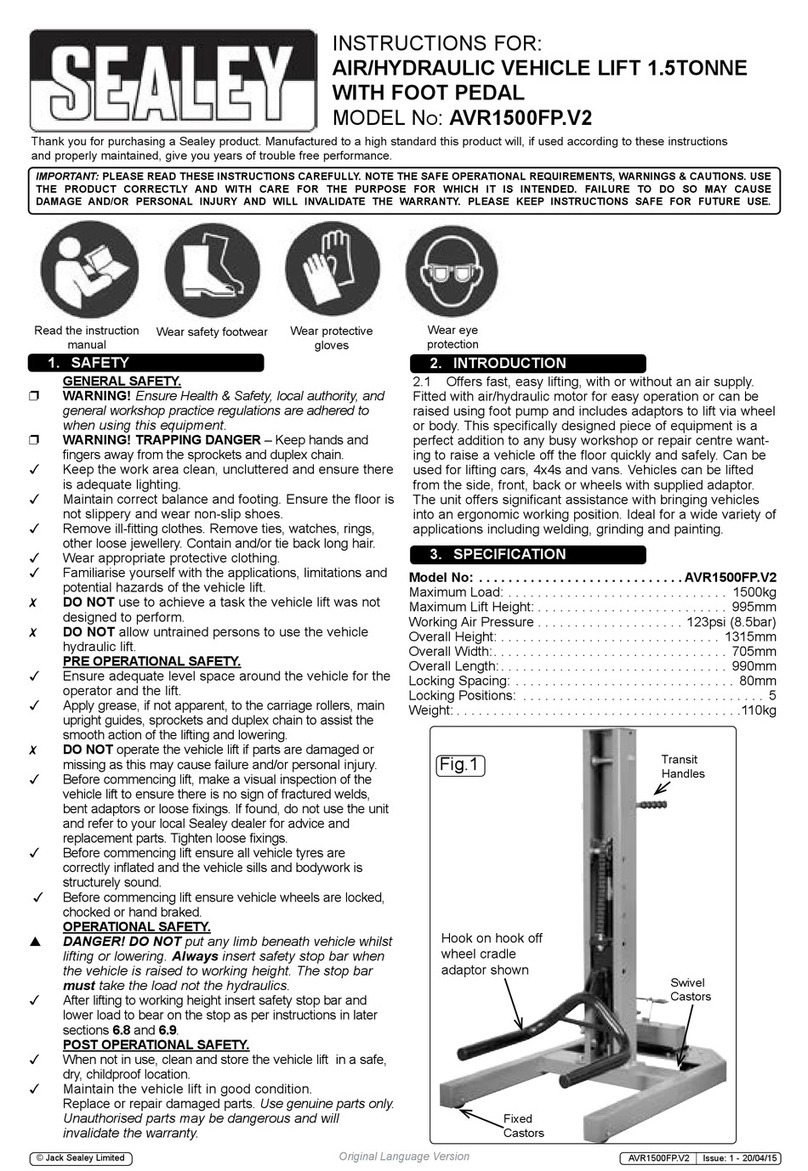

4.1. The fully assembled support beam is very heavy and should be lifted into

place by two people.

4.2. Loosen the grip knobs (6) to allow the assemblies to slide and then locate

the rubber feet into the gutters of the vehicle’s front wing panels or close

to the suspension strut towers.

Note: Refer to the manufacturer’s handbook to identify engine lifting brackets.

4.3. Drop the adjustable screw assemblies through the slot in the main beam

in positions adjacent to the engine lifting points

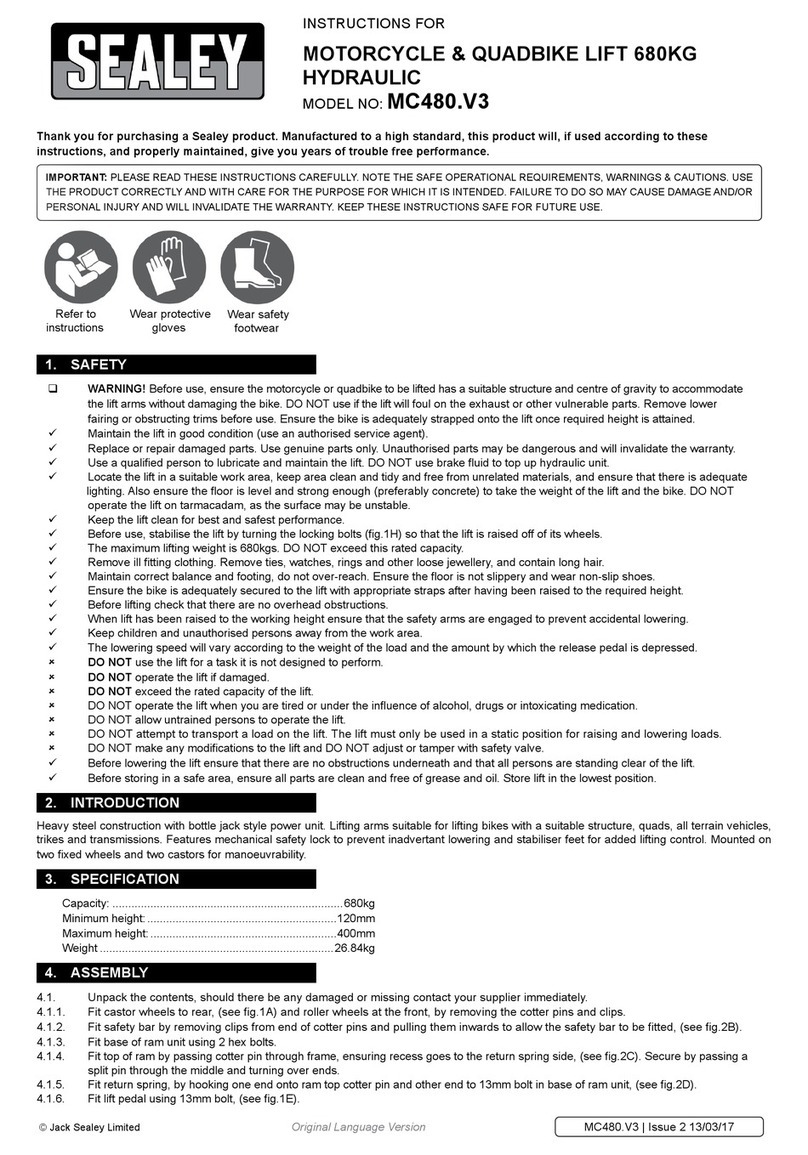

4.4. Attach the ends of the chain to the lifting brackets on the engine.

4.5. The chains may be attached to the lifting hooks in a single or looped

chain configuration.

4.6. Lower the adjustable screws and hook the chains around the hooks. In all

cases ensure that at least one link of the chain is hooked over the lifting

hooks.

4.7. Tighten both grip knobs (6).

4.8. Progressively rotate the lifting handles (2) clockwise to tighten the chains

and support the engine.

4.9. On completion of the maintenance task, rotate the lifting handles

anticlockwise to release the tension on the chains.

4.10. Unhook the chains, loosen both grips (6) and remove the engine support

from the vehicle.

4.11. Remove the chains from the engine lifting points.

ES502.V2 Issue No.1 - 27/06/13

fig.1

Note: Numbers in brackets refer to item numbers shown in fig.1

3.1. Insert a foot (5) into the slot in the standing block (4). Align the holes in

the two components and join them together using an M10 x 30 bolt (10).

3.2. Place a large washer (8) over the upstanding rod on the standing block

Original Language Version

© Jack Sealey Limited