450KG SINGLE POST MOTORCYCLE LIFT

MODEL NO: MCL500

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure that the motorcycle is adequately secured to the lifting platform with appropriate straps before raising the

load.

9Maintain the lift in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Use a qualified person to lubricate and maintain the lift. DO NOT use brake fluid to top up hydraulic unit.

9Locate the lift in a suitable work area, keep area clean and tidy and free from unrelated materials, and ensure that there is adequate

lighting. Also ensure that the floor is level and strong enough (preferably concrete) to take the weight of the lift and the bike. DO NOT

operate the lift on tarmacadam, as the surface may be unstable.

9Keep the lift clean for best and safest performance.

9The maximum motorcycle weight is 450kg. DO NOT exceed this rated capacity.

9Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery, and contain long hair.

9Maintain correct balance and footing, DO NOT over reach. Ensure the floor is not slippery and wear non-slip shoes.

9Before lifting check that there are no overhead obstructions.

9When platform has been raised to the working height ensure the locking pin is engaged to prevent accidental lowering.

9Keep children and unauthorised persons away from the work area.

9The lowering speed will vary according to the weight of the load and the setting of the release valve.

8DO NOT use the lift for a task it is not designed to perform.

8DO NOT operate the lift if damaged.

8DO NOT exceed the rated capacity of the lift.

8DO NOT operate the lift when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT allow untrained persons to operate the lift.

8DO NOT make any modifications to the lift and DO NOT adjust or tamper with the safety valve.

8DO NOT sit or stand on the lift or hold onto it when it is being raised or lowered.

8DO NOT attempt to raise the lift using manual strength.

8DO NOT allow anyone to stand near the interior frame of the lift whilst raising or lowering.

8DO NOT use the ram alone to maintain a raised motorcycle. ALWAYS insert the locking pin.

9Before lowering the lift ensure that there are no obstructions underneath and that all persons are standing clear.

9Before storing in safe area, ensure all parts are clean and free of grease and oil. Store lift in the lowest position.

WARNING! The warnings, cautions and instructions referred to in this manual cannot cover all possible conditions and

situations that may occur. It must be understood that common sense and caution are factors which cannot be built into this

product, but must be applied by the operator.

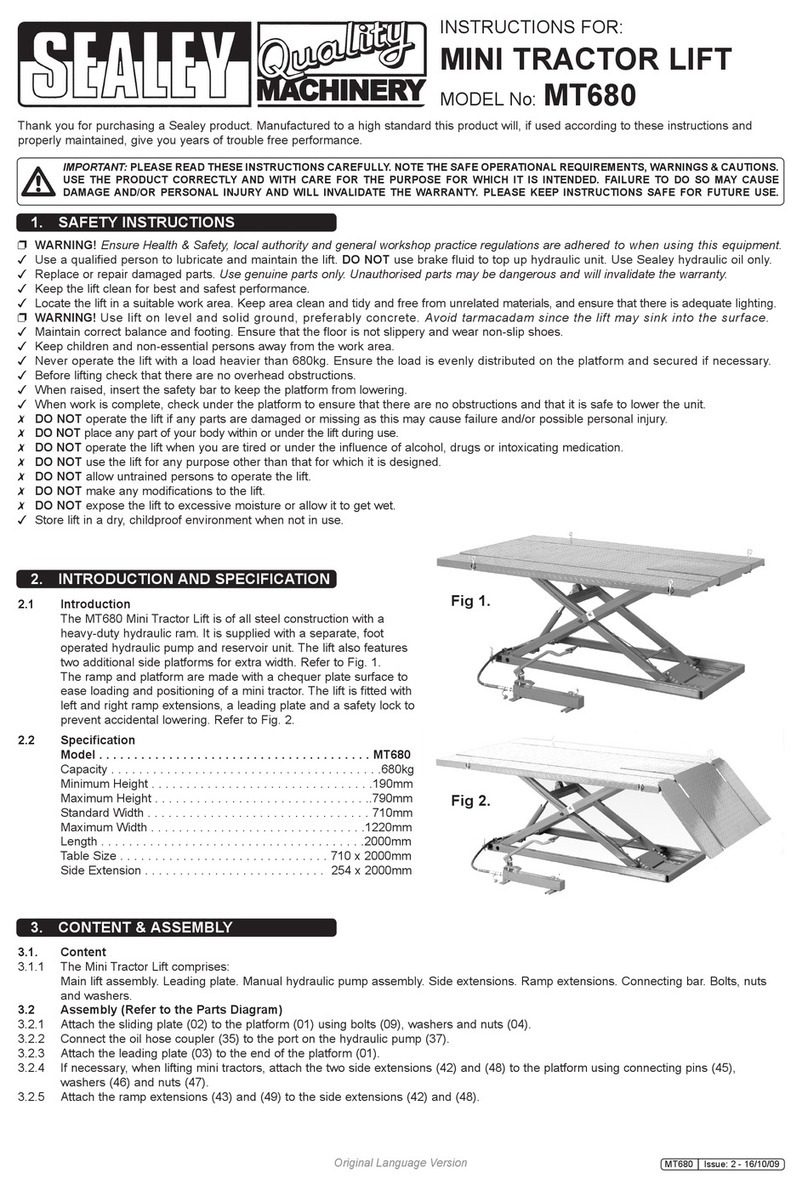

2. INTRODUCTION

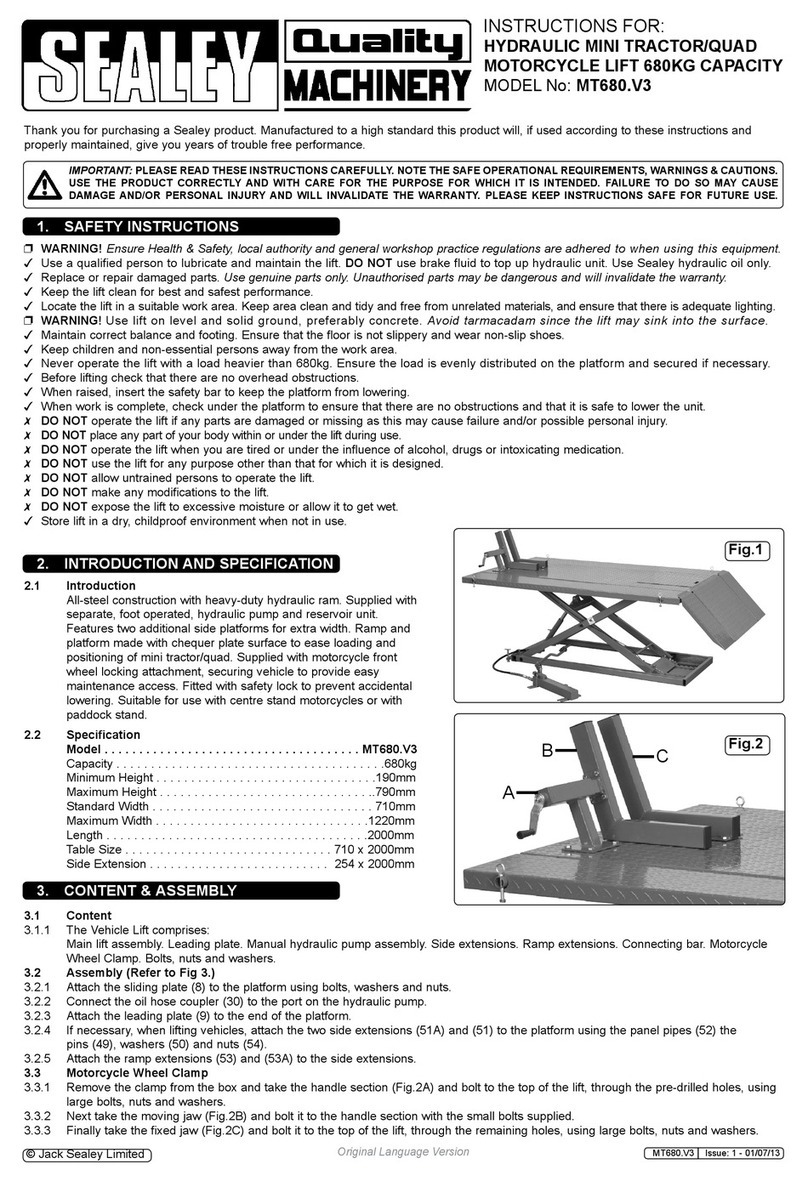

Space saving design maximises garage working area. With a low minimum height of 65mm (without frame supports), it will lift and support

the bike through to a maximum height of 740mm (840mm with frame supports). Lockable in two positions for supporting the motorcycle over

extended periods. Unlike most other motorcycle lifts, it is possible to remove both wheels, front forks, steering assembly, rear swing arm and

suspension units as well as the engine. This lift also benets from being portable and can be used anywhere with a hard level oor, making

this suitable for mobile motorcycle mechanics. Ideal for use with the Sealey range of wheel chocks to assist supporting the motorcycle, whilst

adjusting the frame supports and securing to the lift.

3. SPECIFICATION

Model No:........................................................................................MCL500

Capacity:..............................................................................................450kg

Min./Max. Lift Height (without Frame Supports): ...........................65/740mm

Min./Max. Lift Height (with Frame Supports): ..............................165/840mm

Frame Height: ....................................................................................920mm

Maximum Frame Width: .....................................................................980mm

MCL500 Issue 2 (H2F) 29/04/20

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear safety

footwear

No reaching in