INSTRUCTIONS FOR

DIGITAL DIESEL & FLUID FLOW METER

MODEL NO: TP101.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure health & safety, local authority, and general workshop practice regulations are strictly adhered to when using this

equipment.

9Familiarise yourself with product application and limitations, as well as the specific potential hazards peculiar to this product.

9Maintain the meter in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use genuine parts only. Non authorised parts will invalidate the warranty.

9Use only to meter diesel fuel, kerosene, petrol, water, windscreen washer or water/urea solutions.

9Ensure safety eye protection and protective clothing are worn when using this product.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

9Keep children and unauthorised persons away from the working area.

9After use, drain any fluids from the equipment before storage.

9Dispose of waste liquids in accordance with local authority regulations.

8DO NOT exceed the maximum pressure of 50bar.

8DO NOT use the equipment near open flames.

8DO NOT smoke whilst using this equipment.

8DO NOT use for corrosive fluids.

8DO NOT dismantle, tamper with or adapt the equipment for any purpose other than for which it is designed.

8DO NOT use the unit if it has been dropped or mishandled, check the unit to ensure there is no damage.

8DO NOT use taper connections, use parallel connectors only.

8DO NOT use compressed air on the turbine, the excessive rotation will damage the unit.

9Keep the meter clean and store in a safe dry, childproof location.

WARNING! DO NOT allow uncontrolled discharge of fluids thus polluting the environment. All liquids must be disposed of according to

local authority regulations.

2. INTRODUCTION

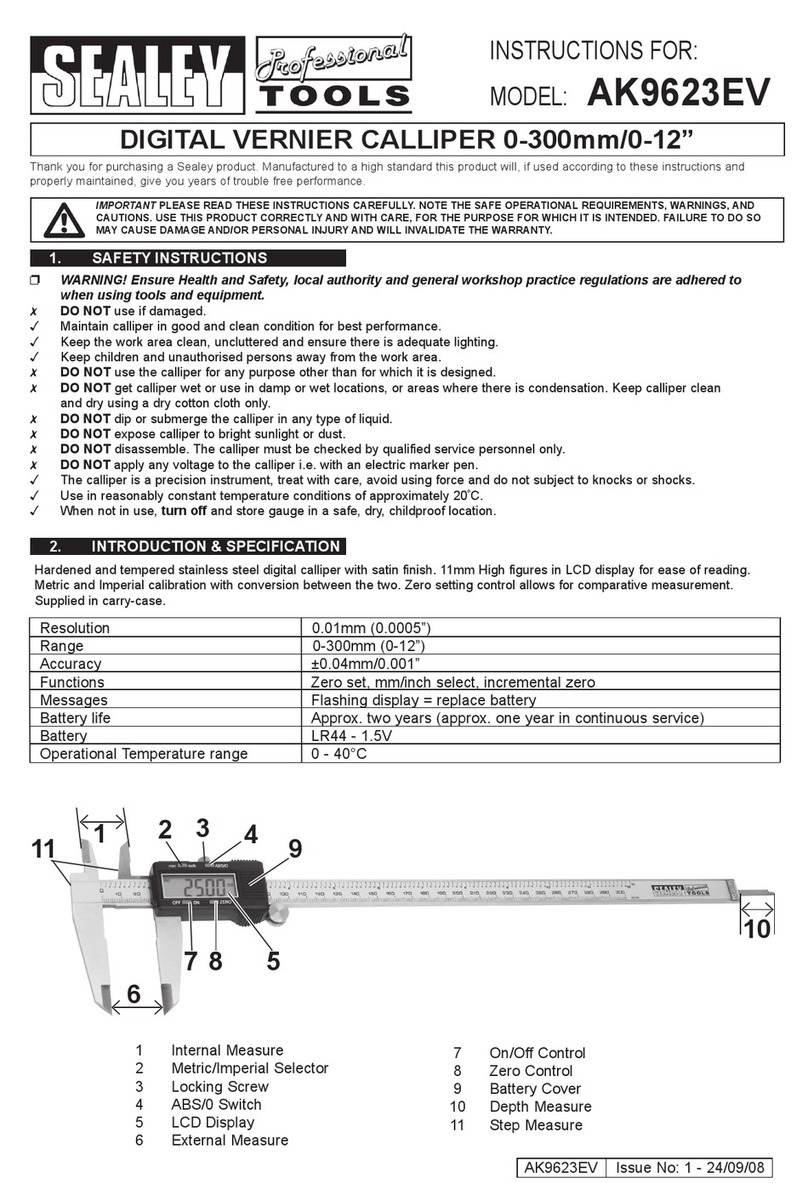

Robust rubber housing with integral digital electronic metering. Easy to read large, four digit, 28mm high LCD display calibrated in litres, quarts,

pints and gallons. Features flow rate indication. 1” x 1” BSP male/female fitting. Powered by 2 x AAA batteries (supplied). IP65 rated protection.

3. SPECIFICATION

Model no:...................................................................TP101.V2

Flow rate:................................................................7-120ltr/min

4. OPERATION

WARNING! DO NOT use the meter without a lter installed BEFORE the meter.

4.1. Installation refer to g's 1 & 3

4.1.1. This is a bi-directional meter with 1” threaded male & female ports. The meter can be xed in any position - xed inline or

mobile on a control nozzle.

4.1.2. Remove the four screws (2) and separate the card housing (5) from the turbine assembly (6).

4.1.3. Rotate the card housing in any of the four positions as shown in g.1 and tighten the card housing with four screws (2)

Refer to

instruction

manual

fig.1

TP101.V2 | Issue:1 30/11/17

Original Language Version

© Jack Sealey Limited