The use of symbols in this document is to attract your attention to possible danger. The symbols and warnings themselves do not eliminate any danger, nor are they substitutes for proper

accident prevention measures.

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

2. INTRODUCTION & SPECIFICATIONS

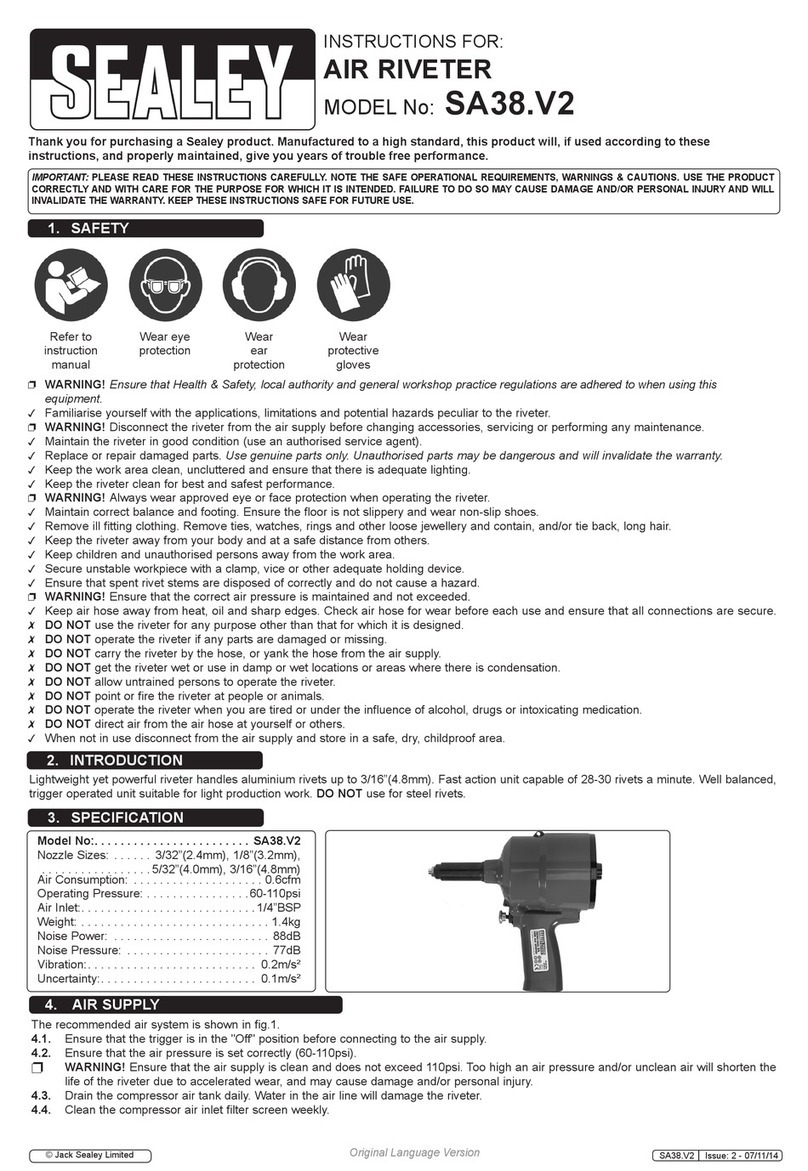

INSTRUCTIONS FOR:

AIR RIVETER

MODEL No: SA312

p WARNING! Ensure health & safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

3Familiarise yourself with this products application and limitations, as well as the specific potential hazards peculiar to the riveter.

p WARNING!Disconnect the riveter from the air supply before changing accessories, servicing or performing any maintenance.

3Maintain the riveter in good condition (use an authorised service agent).

3Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

3Use in a suitable work area. Keep area free from unrelated materials and ensure that there is adequate lighting.

3Keep the riveter clean for best and safest performance.

pWARNING! Always wear approved eye (or face) and hand protection when operating the riveter.

3Maintain correct balance and footing. Do not over reach, ensure the floor is not slippery, wear non slip shoes.

3Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain and/ or tie back long hair.

3 Wear appropriate protective clothing and keep hands and body clear or working parts.

3Keep the riveter away from your body and at a safe distance from others.

3Keep children and unauthorised persons away from the working area.

3Secure non stable work piece with a clamp, vice or other adequate holding device.

3Ensure that spent rivet stems are disposed of correctly and do not cause a hazard.

pWARNING! ensure correct air pressure is maintained and not exceeded. Recommended pressure 70-90psi.

3Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections are secure.

7 DO NOT use the riveter for a task it is not designed to perform.

7 DO NOT operate the riveter if any parts are damaged or missing as this may cause failure and/or personal injury.

3Ensure the safety cap (part 23) is correctly fitted.

7 DO NOT carry the by the hose, or yank the hose from the air supply.

7 DO NOT get the riveter wet or use in damp or wet locations or areas where there is condensation.

7 DO NOT allow untrained persons to operate the riveter.

7 DO NOT operate the riveter when you are tired, under the influence of alcohol, drugs or intoxicating medication.

7 DO NOT direct air from the air hose at yourself or others..

3When not in use disconnect from the air supply and store in a safe, dry, child proof location.

3 Avoid unintentional starting.

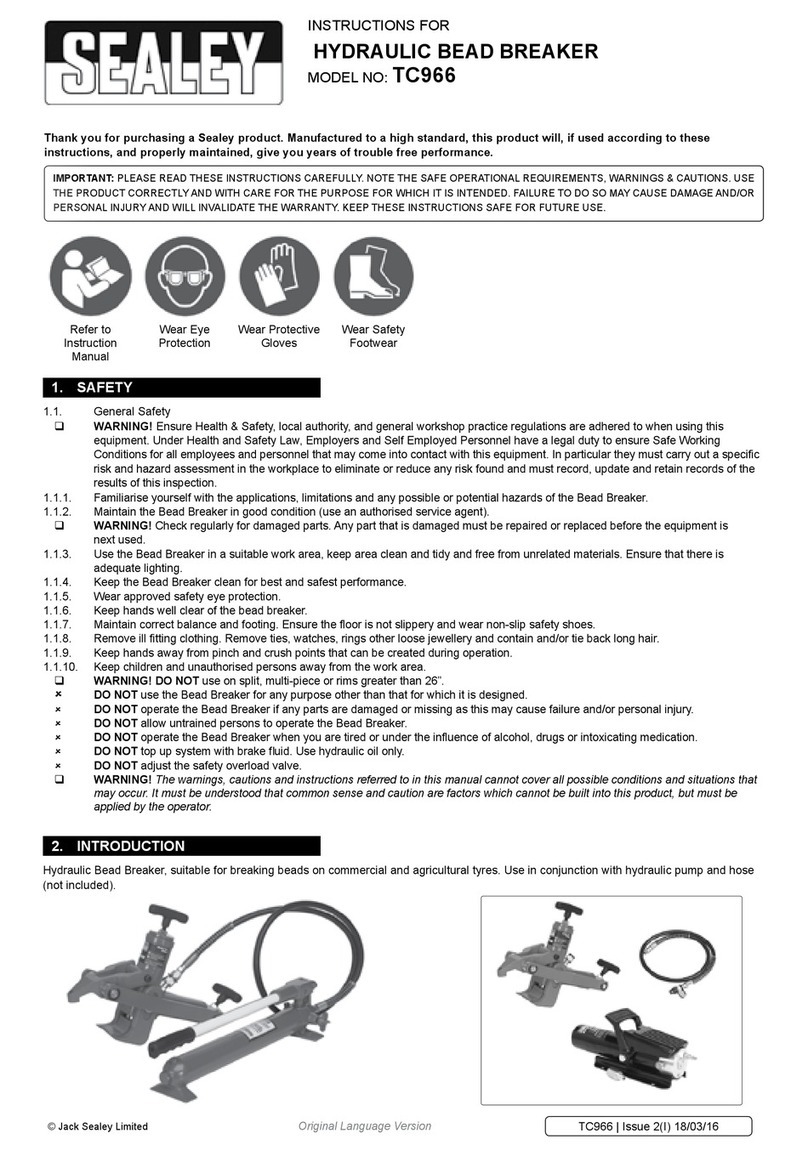

This heavy duty riveter is suitable for both aluminium, steel and stainless steel rivets. Supplied with

rivetting nozzles and spanners. Trigger operated, with hardened steel jaw assembly and rivet shaft safety

cap. The riveter is suitable for heavy assembly work.

Nozzle Sizes:............3/32”(2.4 mm), 1/8”(3.2 mm)

......................5/32”(4.0 mm), 3/16”(4.8 mm)

Air Consumption: ..........................4.0 cfm

Operating Pressure:.........................90 psi

Air Inlet Size: ........................... 1/4” BSP

Weight:...................................1.3 kg

Noise Power: .......................... 87.3dB(A)

Noise Pressure: ........................ 76.3dB(A)

Vibration Figure: .........................1.01m/s²

Uncertainty Figure: ........................0.6m/s²

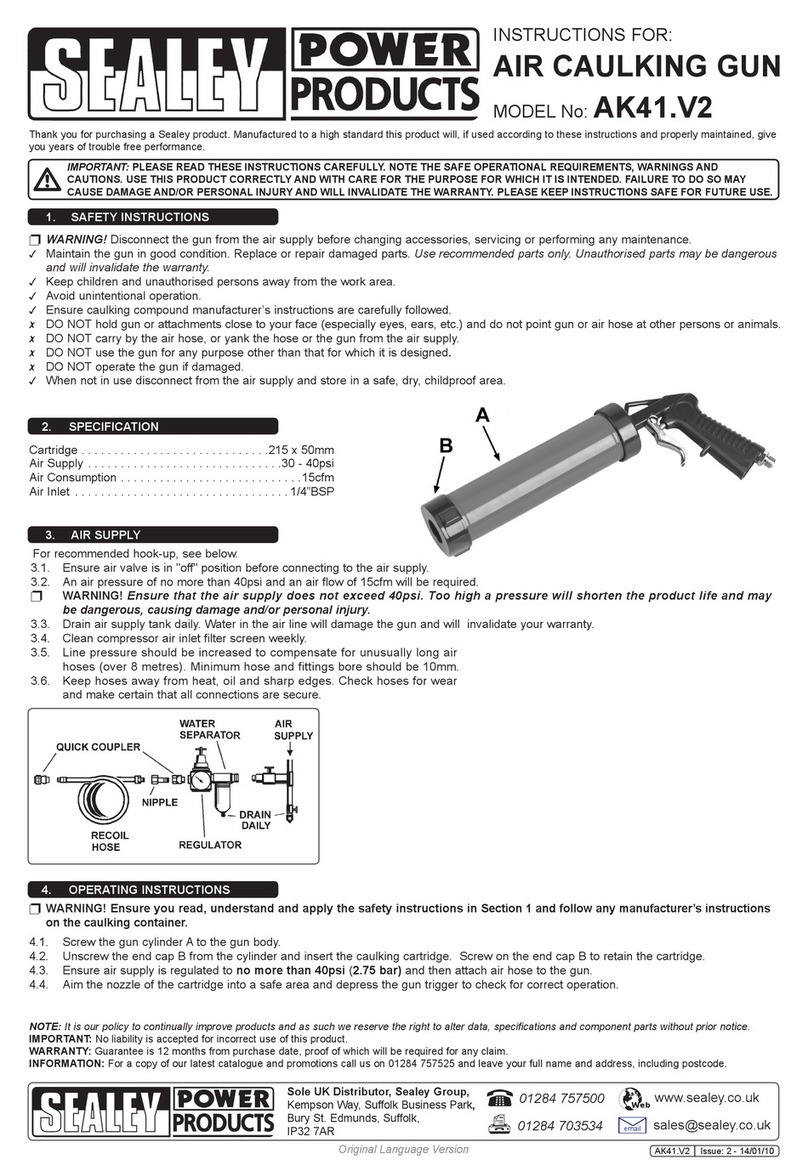

3. AIR SUPPLY

3.1. Air Supply

p WARNING! Ensure the air supply is clean and does not exceed 90 psi while operating the riveter. Too high an air pressure and

unclean air will cause excessive wear, and may be dangerous, causing damage and/or personal injury.

3.1.1. Ensure the riveter air valve (or trigger) is not depressed before connecting to the air supply.

3.1.2. You will require an air pressure between 70-90psi, and an air flow according to the specification above.

3.1.3. Drain the air tank daily. Water in the air line will damage the riveter and invalidate your warranty.

3.1.4. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig 1.

3.1.5. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose diameter should be 1/4” I.D. and fittings must have the same inside dimensions.

3.1.6. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

3.2. Couplings

Vibration may cause failure if a quick change coupling is connected directly to the air drill. To overcome this, connect a leader hose -

Sealey model number AH2R or AH2R/38 - to the riveter. A quick change coupling may then be used to connect the leader hose to the

air line recoil hose. See figs.1 & 2.

Original Language Version SA312 Issue: 4(SP) - 31/07/13

© Jack Sealey Limited