4.4. We strongly recommend that a suitable dust extraction system is used with this unit.

The blast cabinet should be connected to a dust extraction unit. To do so, remove the plastic sealing plate (X) from the rear of the

cabinet and use the same screws to attach the plastic dust outlet. Fit a filter over the dust outlet to ensure that no abrasive is taken

into the extraction unit. Finally, connect the outlet to the extraction unit and use in accordance with the extractor instructions.

5. OPERATION

WARNING! Ensure you have read, understood and apply safety instructions in Section 1 before using the unit.

5.1. A Ceramic Nozzle must be fitted to the gun output head.

5.1.1. Different Ceramic Nozzle sizes will increase or decrease shot blast flow.

5.1.2. The Ceramic Nozzle is fixed to the gun head by loosening the head screw, inserting the Ceramic Nozzle and re-tightening the screw.

5.2. There is a small metal nozzle located within the gun head. This is the Air Jet. The Air Jet may need to be replaced due to general

wear and tear. To fit a replacement Air Jet you will need to remove the Ceramic Nozzle first, and then use a 1/4” Drive 10mm Socket

to remove the old Air Jet and fit a replacement. Air Jet Part No.SB974/23-1.

5.3. Place the workpiece in the centre of the cabinet and ensure you close and latch both side doors.

WARNING! Failure to securely close the doors could result in damage and/or personal injury.

5.4. Turn on the mains power supply and switch on the internal cabinet light.

5.4.1. Turn the air supply on (set to between 40-80psi). If attached, start the dust extraction unit.

5.5. Insert your hands into the rubber gloves inside the cabinet making sure that your fingers are correctly positioned and check that you

are able to easily move your hand and grasp objects correctly.

5.5.1. Grasp the gun with one hand and point the nozzle at the bottom of the cabinet. Depress the trigger to start the blasting process and

to ensure everything is working correctly. If there are any leaks, stop and fix before use. If no flow is achieved, momentarily

cover the gun nozzle in order to force the compressed air back through the grit hose to clear any lodged media.

5.5.2. Hold the work piece with the other glove. Hold and move the workpiece to ensure you keep glove and fingers out of the abrasive blast.

8DO NOT aim the blast at your fingers, gloves or the internal light.

5.6. Aim the nozzle directly at the surface of the workpiece and move the blast media (which looks like steam) continuously over the

workpiece in an even and circular motion. To avoid undesirable peening, the flow should not be too hard or concentrated. The work

finish may vary from coarse to fine depending on the size of the abrasive media. On delicate workpieces, to avoid unnecessary

peening or excessive abrasion, begin the blasting with a low airflow.

5.7. Before opening the cabinet to check progress or to access content, release the trigger and lay the gun on the mesh shelf. Remove your

gun hand first and then your other hand. Only then is it safe to open the side door.

5.8. When work is complete, disconnect gun from the air line, unplug from the mains electrical supply and switch off dust extraction.

6. MAINTENANCE

WARNING! Ensure the cabinet is disconnected from the electrical mains and the air supply before attempting any maintenance.

6.1. Keep the blast cabinet clean and dry. DO NOT use abrasives to clean the unit.

6.2. Ensure the blasting media does not become damp. Keep the air supply dry at all times. Dispose of any damp media.

6.3. Replace media when it has become excessively dusty, lost its granular or spherical appearance, or when workpiece debris has mixed

in with it. This is usually noticed when media from the nozzle looks like a smoke cloud rather than steam.

6.4. To change media, place an appropriate container under funnel outlet and turn the locking lever to open. Wear a dust mask when

performing this task.

6.5. If used, regularly check that the exhaust vent at the back of the cabinet (fig 1.Z) is clear.

6.5.1. If you use an extraction unit change the filter from time to time, according to use.

6.6. Regularly check gun blast nozzle to ensure that it does not become blocked with media. Immediately replace worn or damaged nozzles.

6.7. If the abrasive pick-up hose becomes blocked, ensure the doors are correctly closed and then re-power the unit. Cover the gun tip to

force air back through the hose to clear any media.

6.8. The transparent screen has a replaceable covering on the underside of the lid. If visibility is reduced, replace the protective cover.

6.9. Check that the gloves are in good condition. If damaged, replace immediately.

6.10. TO REPLACE INTERNAL CABINET LIGHT:

6.10.1. Un-clip light unit from each end clamp. Remove each plastic end (these are a tight fit). Disconnect the electrical terminals and gently

slip the rubber retaining rings from the tube releasing it from the back reflector. Use a light tube not greater than 70 watts.

7. TROUBLESHOOTING

Original Language Version

© Jack Sealey Limited

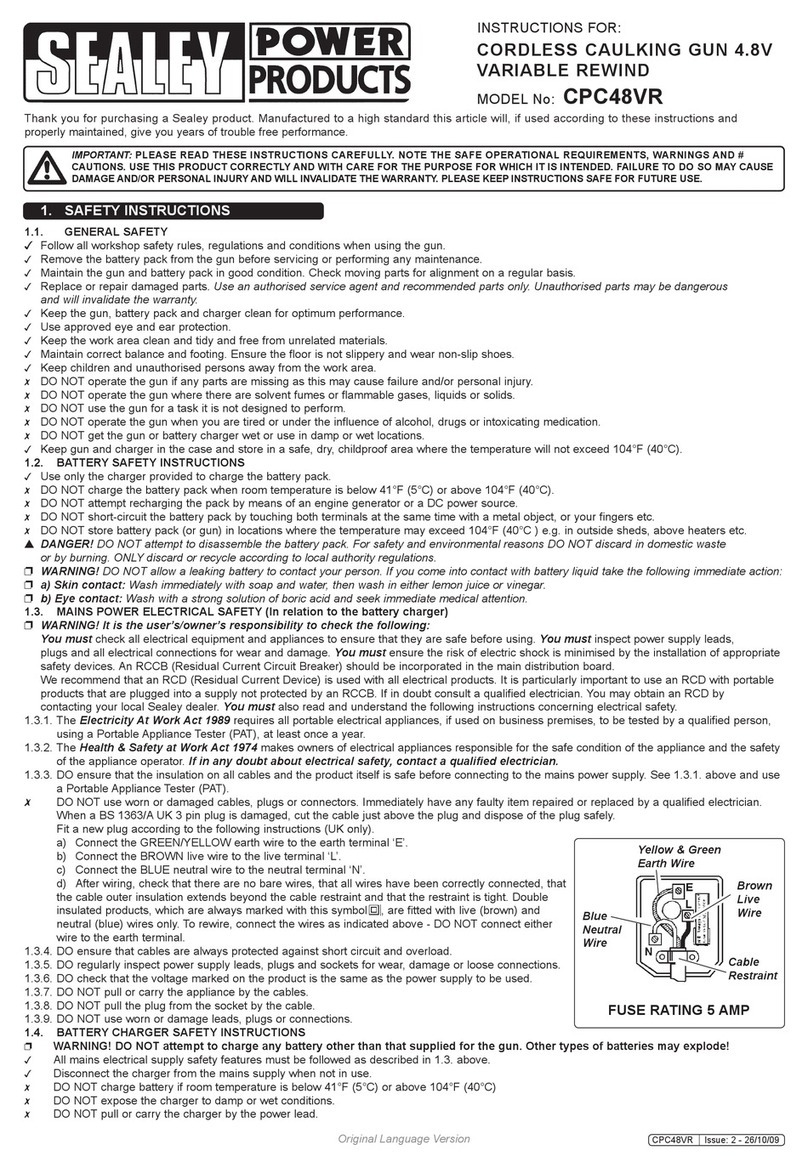

PROBLEM POSSIBLE CAUSE REMEDY

Excessive dust in the cabinet. 1. Exhaust vent or air flow is blocked.

2. Abrasive is worn.

3. Too much abrasive in the cabinet

4. Loose air line or fittings.

1. Clean vent and keep vent away from any wall.

Connect to a suitable dust extraction system.

2. Replace.

3. Remove excess.

4. Check and tighten all air fittings.

Uneven blasting. 1. Too much abrasive in cabinet.

2. Moisture inside cabinet.

1. Remove excess.

2. Check air line for moisture.

Inadequate speed or efficiency of blast. 1. Abrasive is worn.

2. Pressure is too low.

1. Replace.

2. Check that there are no supply blockages or leaks.

Increase pressure. Recommended 40-80psi, Max:90psi

Static electricity. 1. Dry weather conditions. 1. Leave the workpiece to stand for a while.

Blast pattern too wide or ineffective. 1. Nozzle blocked or worn. 1. Unblock or replace nozzle

SB974.V5 Issue 3 (3,4) 21/08/19