8DO NOT insert foreign objects or material into the hole reserved for the battery.

8DO NOT force the battery into the charger. The battery will only fit one way to ensure correct polarity alignment.

8DO NOT charge a second battery immediately. Consecutive charging will overheat the charger. Allow the unit to cool for 15 minutes

before charging the next battery.

9Store the charger in the same manner as the battery, see section 1.2.

1.3. GENERAL SAFETY.

9Maintain the drill and battery in good condition. Check moving parts alignment on a regular basis.

9Replace or repair damaged parts. Use an authorised service agent and recommended parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

9Ensure the drill is switched off before installing the battery pack.

9Keep the drill and charger clean for best and safest performance.

9Remove ill tting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

9Evaluate your working area before using the drill; e.g. ceilings, oors and enclosures may contain electrical items or water piping

9Ensure battery pack is correctly inserted into the drill handle and latched in place before attempting to switch on drill.

9Secure loose work pieces with a clamp, vice or other adequate holding device.

9Avoid unintentional starting.

9Wear approved safety eye protection (standard spectacles are not adequate).

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-skid shoes.

9Be aware that this drill does not need to be plugged into the mains power.

9Keep chuck direction switch in the locked position until the drill is required for use.

9Keep children and unauthorised persons away from the working area.

8DO NOT use the drill where there are ammable liquids, solids or gases, such as paint solvents, etc.

8DO NOT allow children to operate the drill.

8DO NOT operate the drill if any parts are missing as this may cause failure and/or personal injury.

8DO NOT hold unsecured work piece in your hand.

8DO NOT leave the drill operating unattended.

8DO NOT carry the drill with your finger on the power switch. Keep chuck direction switch in the locked position.

8DO NOT use the drill for a task it is not designed to perform.

8DO NOT operate the drill when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT get the drill or battery charger wet or use in damp or wet locations.

2. INTRODUCTION

Compact, lightweight cordless drill/driver with added hammer function. Comfortable composite housing with soft grip to reduce vibration.

The drill has 0.8-10mm keyless chuck. With 2 speed settings and 21 torque settings gives control to complete various tasks.

Integral LED battery level indicator and LED work light. Complete with belt hook for safer storage while not in use. Requires Model

No.CP1200BP 12V 1.5Ah Lithium-ion battery and Model No. CP1200MC battery charger.

3. SPECIFICATION

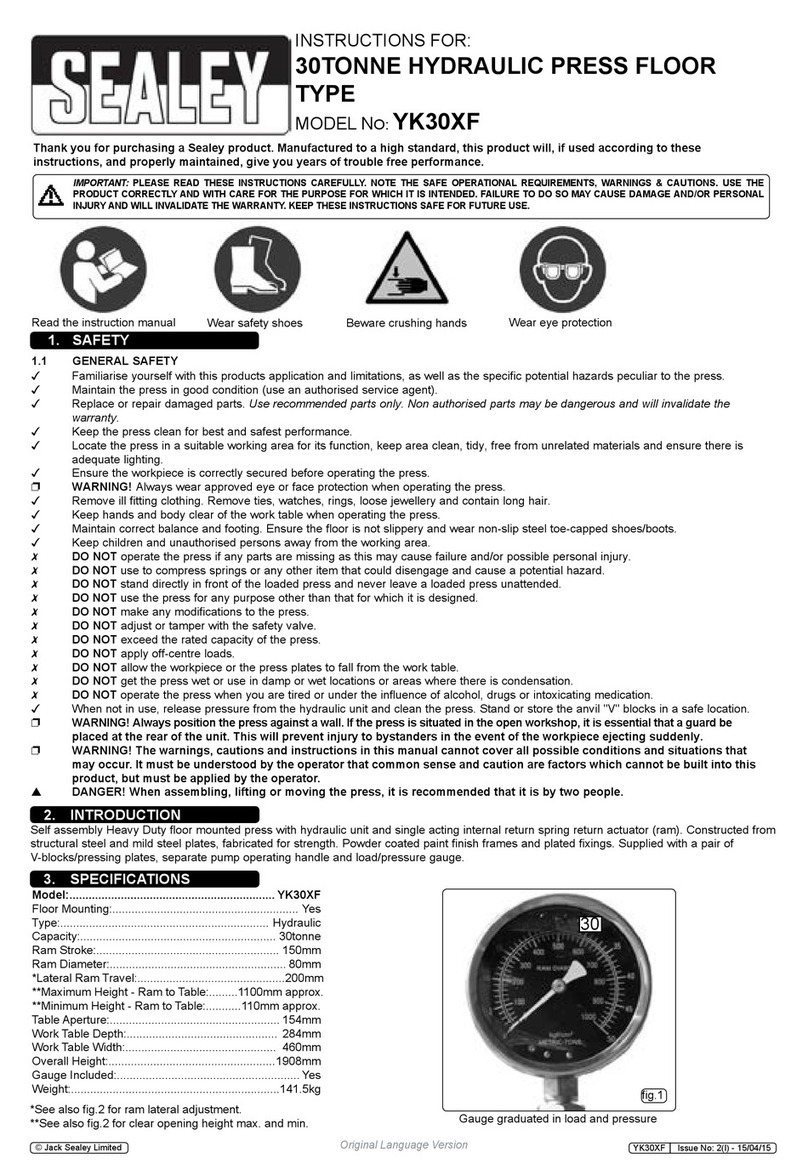

Model No................................................................... CP1201

Battery .................................. 12V 1.5Ah Li-ion (not included)

No Load Speed ...........................................0-400/0-1300rpm

Impact Rate............................................ 0-6000/0-19500bpm

Noise power: ................................................................94dBA

Noise pressure:............................................................84dBA

Drilling Capacities

Wood............................................................................ 20mm

Metal ............................................................................ 10mm

Concrete ...................................................................... 10mm

Chuck Size................................................................... 10mm

Maximum Torque...........................................................25Nm

Battery Model No ..................................................CP1200BP

Mains Charger Model No .....................................CP1200MC

Weight......................................................................... 0.85kg

4. CHARGING

4.1. Battery Pack Removal and Replacement

4.1.1. Switch the machine off before removing the battery pack.

4.1.2. Press the battery latches in (Located either side of grip

and withdraw the battery pack (g.1).

4.1.3. To replace the battery pack, push the stem into the drill

until the latches engage. The battery pack can only be

inserted in the correct orientation.

4.2. Battery Charging

4.2.1. Batteries that have been out of use for some time or are new

may not accept a full charge. This is not a battery fault; the

battery may need to be discharged and charged a couple of

times to restore full capacity.

4.2.2. Connect the charger to the electric power supply. A ashing

green LED will show.

4.2.3. Insert the battery into the charger. A steady red light

will show.

4.2.4. When fully charged, a steady green LED will show.

4.2.5. The battery is ready for use.

4.2.6. g.1

Original Language Version

© Jack Sealey Limited CP1201 | Issue2(SP) 30/08/17