INSTRUCTIONS FOR:

RIVET &THREADED NUT RIVET KIT

Model No: AK39602

Thank you for purchasing a Sealey Rivet Kit. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

3. INTRODUCTION

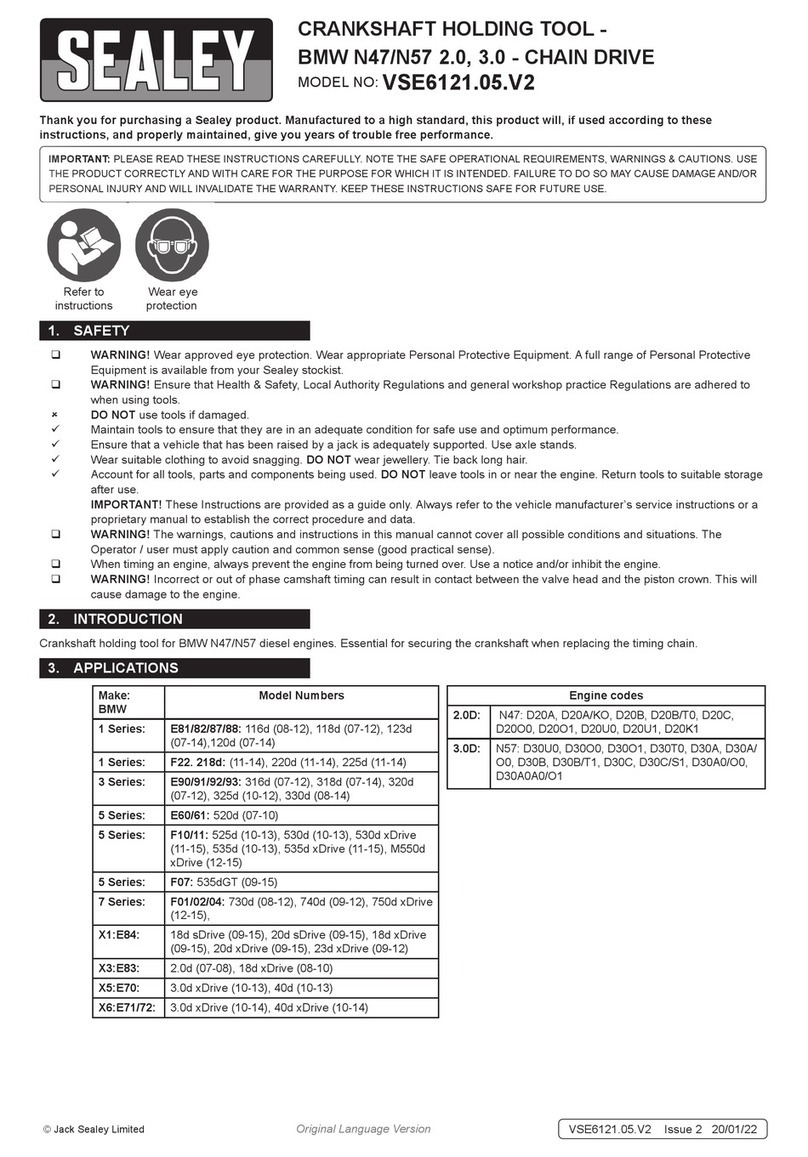

4. APPLICATIONS

pWARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

3Familiarise yourself with the application and limitations of the riveter, as well as the potential hazards.

3Maintain the riveter in good condition (use an authorised service agent).

3Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

3Keep the work area clean, uncluttered and ensure that there is adequate lighting.

3Keep the riveter clean for best and safest performance.

pWARNING! Always wear approved eye or face protection when operating the riveter.

3Keep children and unauthorised persons away from the work area.

3Check moving parts alignment on a regular basis.

7DO NOT hold the workpiece by hand. Secure workpiece with a clamp, vice or other adequate holding device.

7DO NOT use the riveter for any purpose other than that for which it is designed.

7DO NOT operate the riveter if any parts are damaged or missing, as this may cause failure and/or personal injury.

3When not in use return to the case and store in a safe, dry, childproof area.

The AK39602 kit is suitable for fitting threaded nut rivets of the following materials

and sizes together with pop rivets up to 6.4mm (1/4) diameter.

M4 x 0.7 M5 x 0.8 M6 x 1.0 M8 x 1.25 M10 x 1.5

Aluminium 33333

Steel 33333

fig. 1

Drop forged frame with patented folding mechanism for compact storage.

Comfortable cushion grips. Suitable for installing threaded nut rivets for

securing threads in thin sheet material. Heavy-duty head accepts threaded

rivets up to M10. Suitable for aluminium and steel nut rivets and pop rivets.

5. OPERATION

2. CONTENTS

5.1. Pop Rivets

5.1.1. Select the mandrel (fig. 2.A) which matches the shaft diameter of the rivet and screw it to the nosepiece (fig. 2.B) of the riveter.

5.1.2. With the riveter handles extended and open, fully insert the rivet shaft into the mandrel.

5.1.3. Place rivet in hole in the workpiece and squeeze the riveter handles closed to deform the rivet.

5.1.4. If the rivet stem does not shear, open the handles, push the riveter further onto the stem and

then close the handles again.

5.1.5. When the stem shears, open the handles and remove the stem from the riveter.

5.2. Threaded Nut Rivets

5.2.1. Unscrew the pop rivet nosepiece (fig. 2.B) from the riveter body.

5.2.2. Unscrew the jaw case assembly (fig. 4) from the draw bar body (fig. 2.F).

5.2.3. Screw the nut rivet nosepiece (fig. 2.C) into the riveter body.

5.2.4. Screw the appropriate mandrel bar (fig. 2.D) into the draw bar body. Note left-hand thread.

5.2.5. Screw the corresponding mandrel (fig. 2.E) into the nosepiece.

Note: Always use mandrel and mandrel bar of the same size, determined by the size of nut rivet.

To ensure that the nut rivet is compressed by the correct amount it is necessary to set the height

of the mandrel by doing the following test.

5.2.6. Prepare a sample of the workpiece material with a hole slightly larger than the nut rivet diameter.

5.2.7. Screw the nut rivet fully onto the mandrel bar.

5.2.8. Place the nut rivet in the hole in the sample and press down so that the nut flange is held firmly against the

upper face of the sample.

AK39602 -1 - 160603

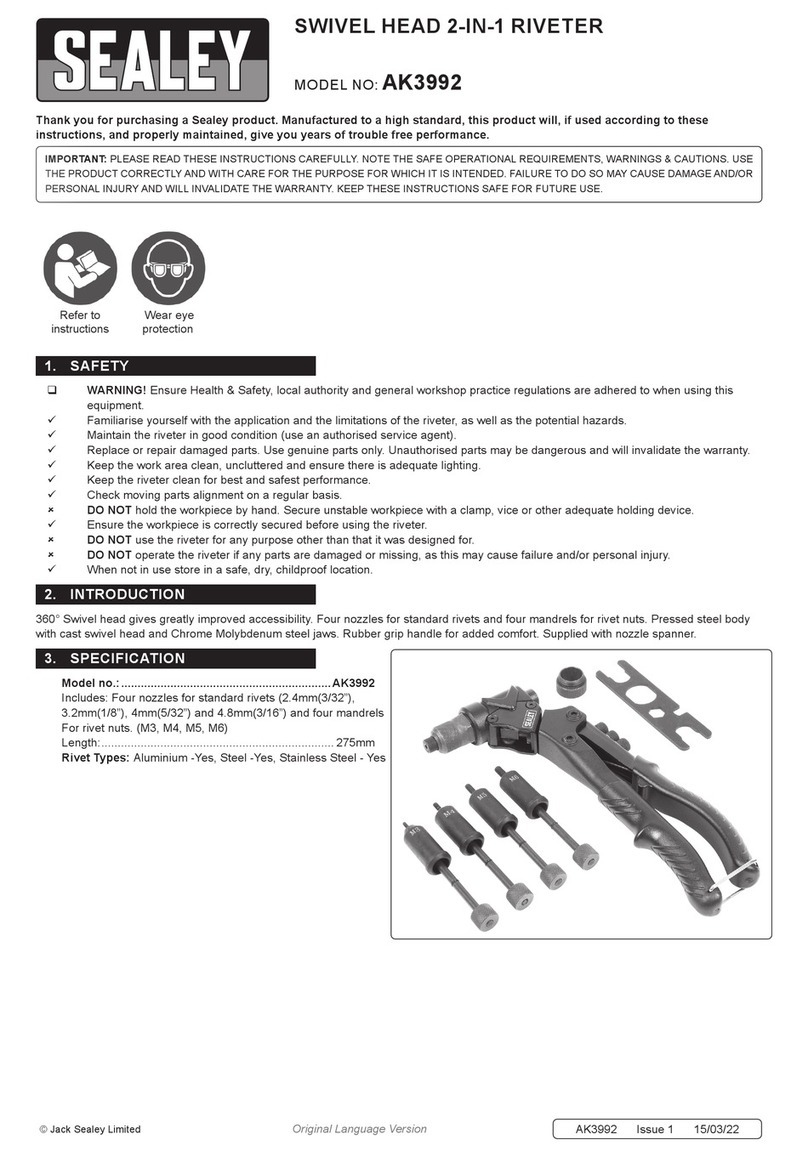

fig. 2

Check the contents of the kit against the item list and fig. 1. If any item is found to be damaged or missing

contact your dealer immediately.

1. Riveter

2. Pop Rivet Mandrels, 5 (1 in riveter)

3. Nut Rivet Mandrels & Bars, 5, M4 x 0.7, M5 x 0.8, M6 x 1.0, M8 x 1.25, M10 x 1.5

4. Nosepiece for Nut Rivet Mandrel

5. Spanners, 5.5/8.5mm, 12/17mm, 15/19mm