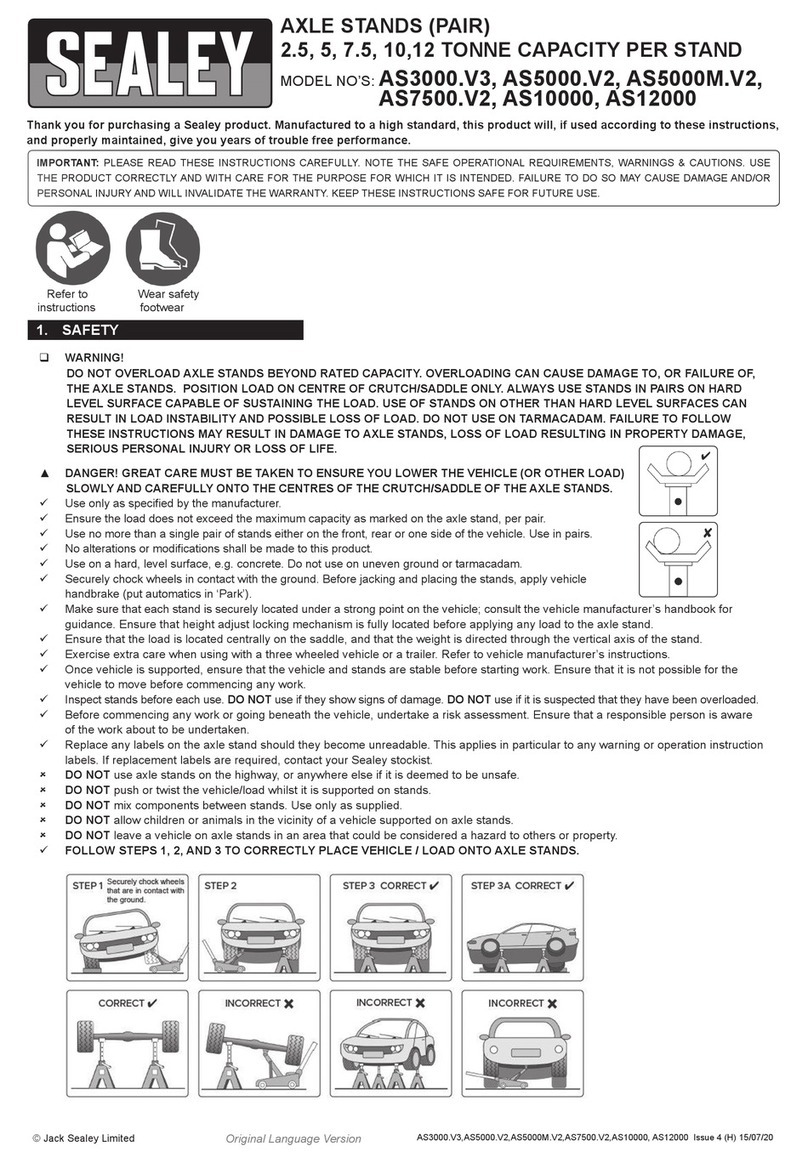

The SEALEY HEADLAMP BEAM SETTER, HBS971 series, is supplied with a rotating column, mirror and visor. The HBS97 series has the

addition of a rail set. Either HEADLAMP BEAM SETTER may be used for checking headlights on cars, heavy goods vehicles and motorcycles.

SPECIFICATION: Height . . . . . . .1750mm Maximum height of beam measurement . . . . . . .1410mm

Width . . . . . .650/670mm Minimum height of beam measurement . . . . . . . .240mm

Length . . . . . . . .690mm Focal length . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500mm

A BASE

BCOLUMN

CVERTICAL SLIDING SYSTEM

2.1. Insert the pivot pin end of column B into the bearings in base A.

2.2. Retain column by screwing special washer onto end of pivot pin.

2.3. Lock column using brake pedal F. If necessary, realign pedal on

shaft by loosening the two clamp screws, rotating pedal to a

suitable position and retightening the screws.

2.4. Attach mirror-visor D to mounting plate at the top of column B with

the two screws provided (in end of visor).

2.5. Fit the optical system E to the vertical sliding system C using the two

screws and washers provided (fit larger washer over slotted hole).

HBS97A & HBS971A - 2 - 281003

1. DESCRIPTION

2. ASSEMBLY

3. WORKING SURFACE

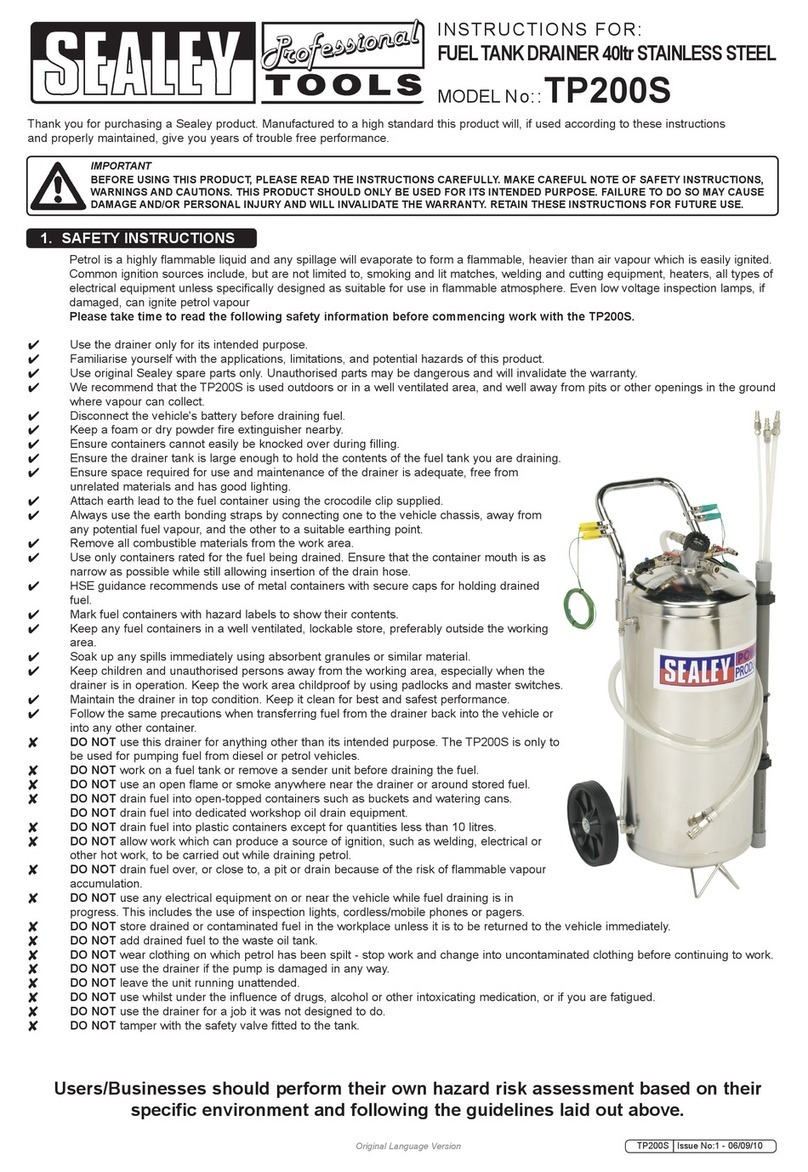

3.1. Position the vehicle on the designated headlamp aim standing area.

3.2. When positioning the HBS ensure the floor is perfectly even and level.

3.3. If this is not possible the vehicle and HBS must be on the same slope, which must not exceed 0.5º.

3.4. Headlights must not be checked where surface angle exceeds 0.5º (see fig. 2).

OK

fig. 2

fig. 1

NO NO0.50 MAX

GENERAL RULES

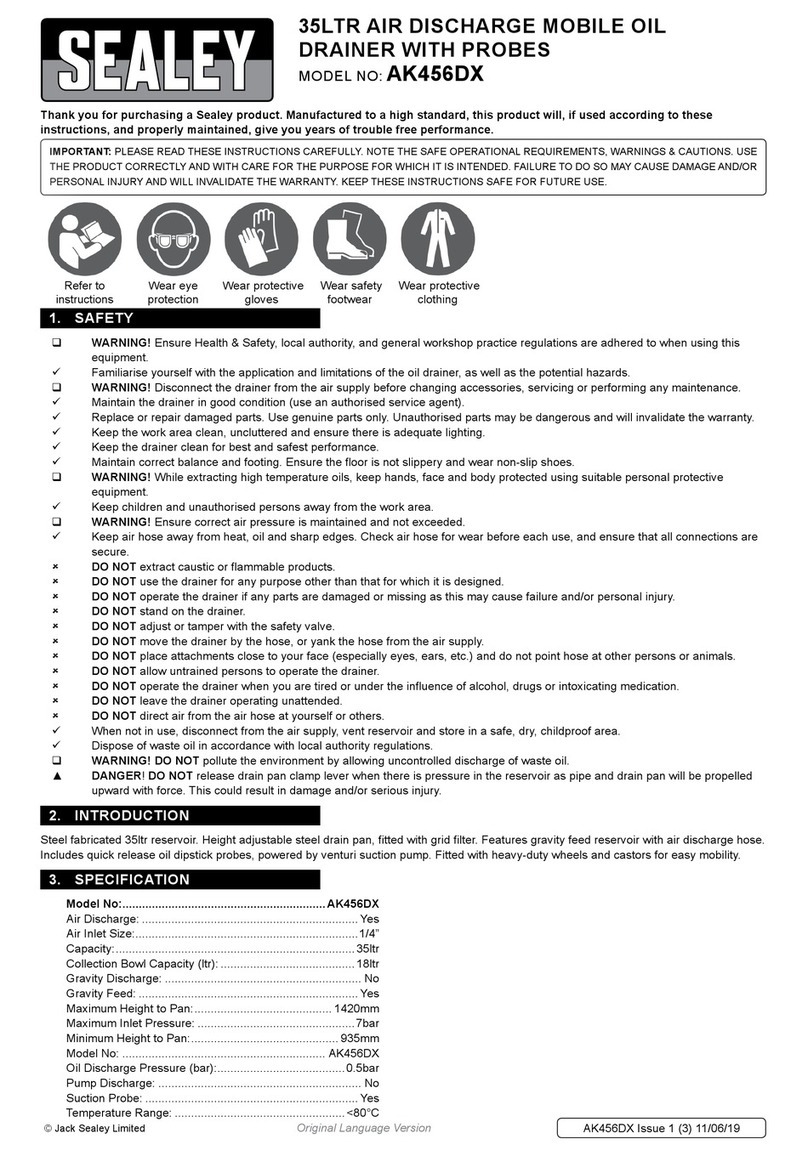

Read instruction manual carefully before using the headlamp beam setter (HBS).

TO AVOID DAMAGE ENSURE THE FOLLOWING ARE STRICTLY APPLIED.

DO NOT allow unqualified persons to operate the HBS.

DO NOT use the HBS in direct sunlight.

DO NOT splash the HBS with water or any other liquid.

DO ensure the work area is well ventilated.

DO ensure that there is good lighting.

DO apply handbrake on vehicle.

DO avoid sudden changes in temperature.

DO avoid sudden vibration.

INSTRUCTIONS FOR:

UNIVERSAL HEADLAMP BEAM SETTER

Models: HBS97A &HBS971A

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

4. 1. Straighten vehicle wheels.

4. 2. Check the tyre pressures.

4. 3. Ensure the headlights are clean and dry.

4. 4. If the vehicle is fitted with manual or electric headlamp levelling device, ensure this is set for vehicle with normal load.

4. 5. Remove anything which could alter the attitude of the vehicle, i.e. load, snow, ice, mud, etc.

4. VEHICLE PREPARATION

IMPORTANT

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

D MIRROR-VISOR

EOPTICAL SYSTEM

FBRAKE