INSTRUCTIONS FOR:

PALLET TRUCKS

MODEL No: PT1150.V2 & PT1220.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

2. INTRODUCTION & SPECIFICATION

DO NOT use a faulty or damaged truck.

Before using the truck all parts and working mechanisms should

be checked for wear or damage. Pay particular attention to the

wheels, handle and fork lifting and lowering mechanism. Any

parts found to be worn, damaged or suspect should be repaired

or replaced before the truck is used.

All repairs must be carried out by an authorised Sealey service

agent.

Personnel who operate the truck and those in the vicinity of

operation should wear safety shoes with reinforced toe caps at all

times.

Never place any part of your body in the lifting mechanism or

under the forks or load.

DO NOT allow others to ride on the truck.

DO NOT lift or move unstable or loosely stacked loads.

Take special care when moving long, high or wide loads in order

not to dislodge the load by striking any architectural features,

permanent fixtures, vehicles or people in the area of operation.

Always ensure that the load is evenly distributed across the forks

with the centre of the load being at the halfway point of the length

of the forks.

Do not overload the truck - refer to the specification for maximum

permitted load.

If a load is left unattended even for a very short period of time it

should be lowered to the ground.

When not in use the truck should be left in the lowered position.

Ensure that the width and length of the forks is correct for the

pallet to be lifted.

Ensure that the truck is sufficiently inserted into the pallet to lift

the full depth of the pallet.

Use the truck on level, flat, hard surfaces.

DO NOT use truck on sloping or uneven ground and do not

attempt to negotiate curbs, steps or ramps.

The operator of the truck must be physically capable of controlling

the load selected; particularly in relation to stopping a rolling load.

When the truck is not in use, lower the forks and park the truck

where it will not be a hazard.

3. ASSEMBLY

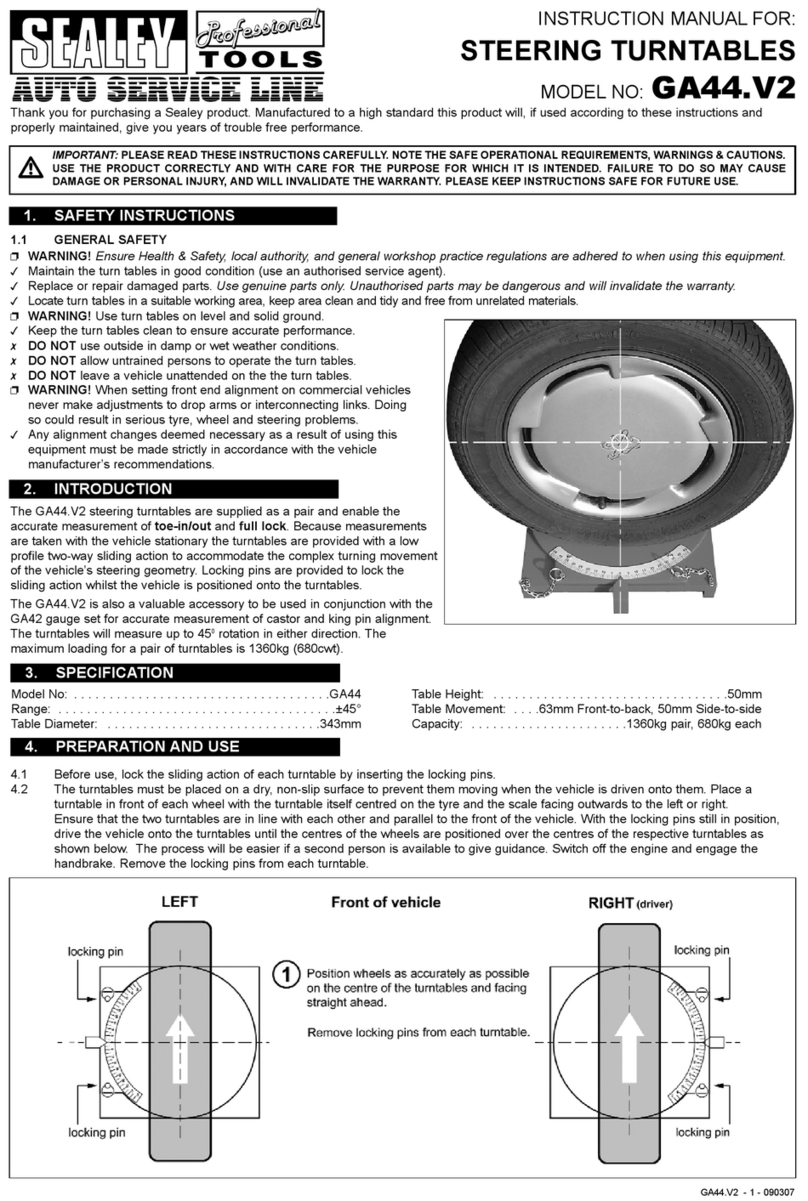

Introduction. Heavy-duty trucks suitable for warehouse and general

handling duties. Polyurethane, non-marking wheels and tandem

loading rollers with sealed-for-life bearings all-round. Hydraulic unit

with chromed ram and piston for resistance to corrosion. Single

bogey wheels with drop nose for smooth pallet entry.

Specification.

Model No. ....................................... PT1150.V2 ...............PT1220.V2

Capacity................................................. 2500kg .....................2500kg

Minimum height ....................................... 85mm .......................85mm

Maximum height ................................... 200mm ......................200mm

Fork Length ......................................... 1150mm ...................1220mm

Width over Forks ................................... 540mm.................. 685 mm

Fork Spread........................................... 230mm ......................365mm

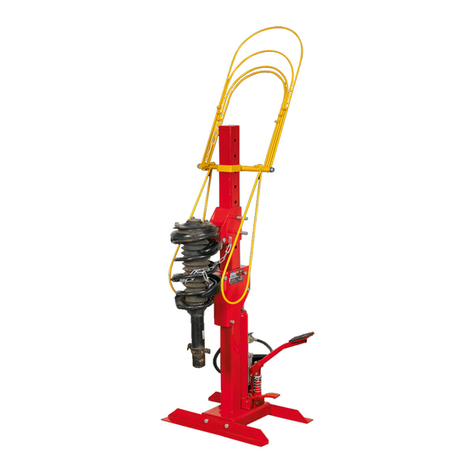

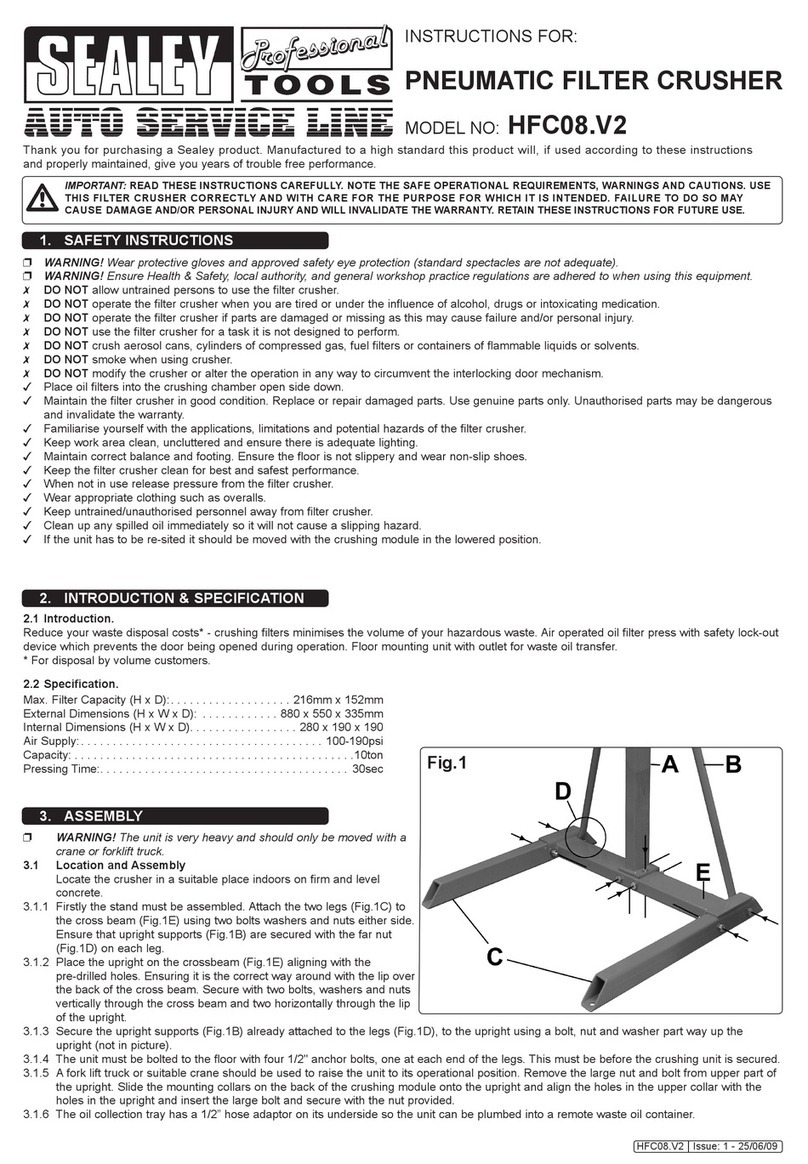

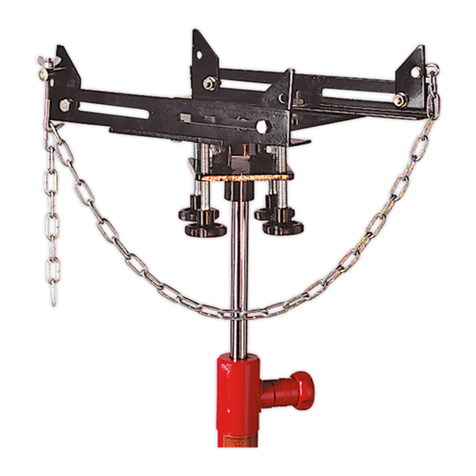

roll pin will lie in the groove made for it in the pump casting.

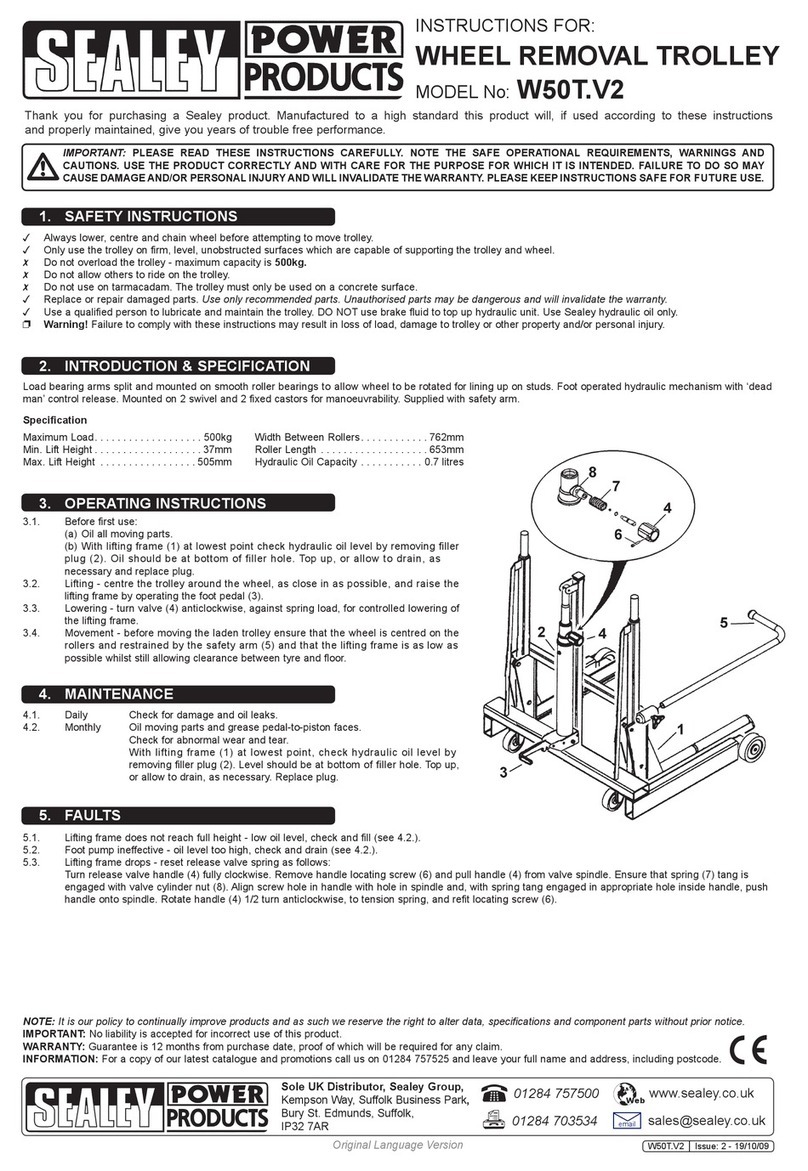

3.3 Using a hammer, insert the pivot pin (5) through both

components from right to left. Once the pivot pin is in

position, drive another roll pin through the hole in the other

end of the pivot pin.

3.4 Move the lever control at the top of the handle into it's highest

position and hold it there.

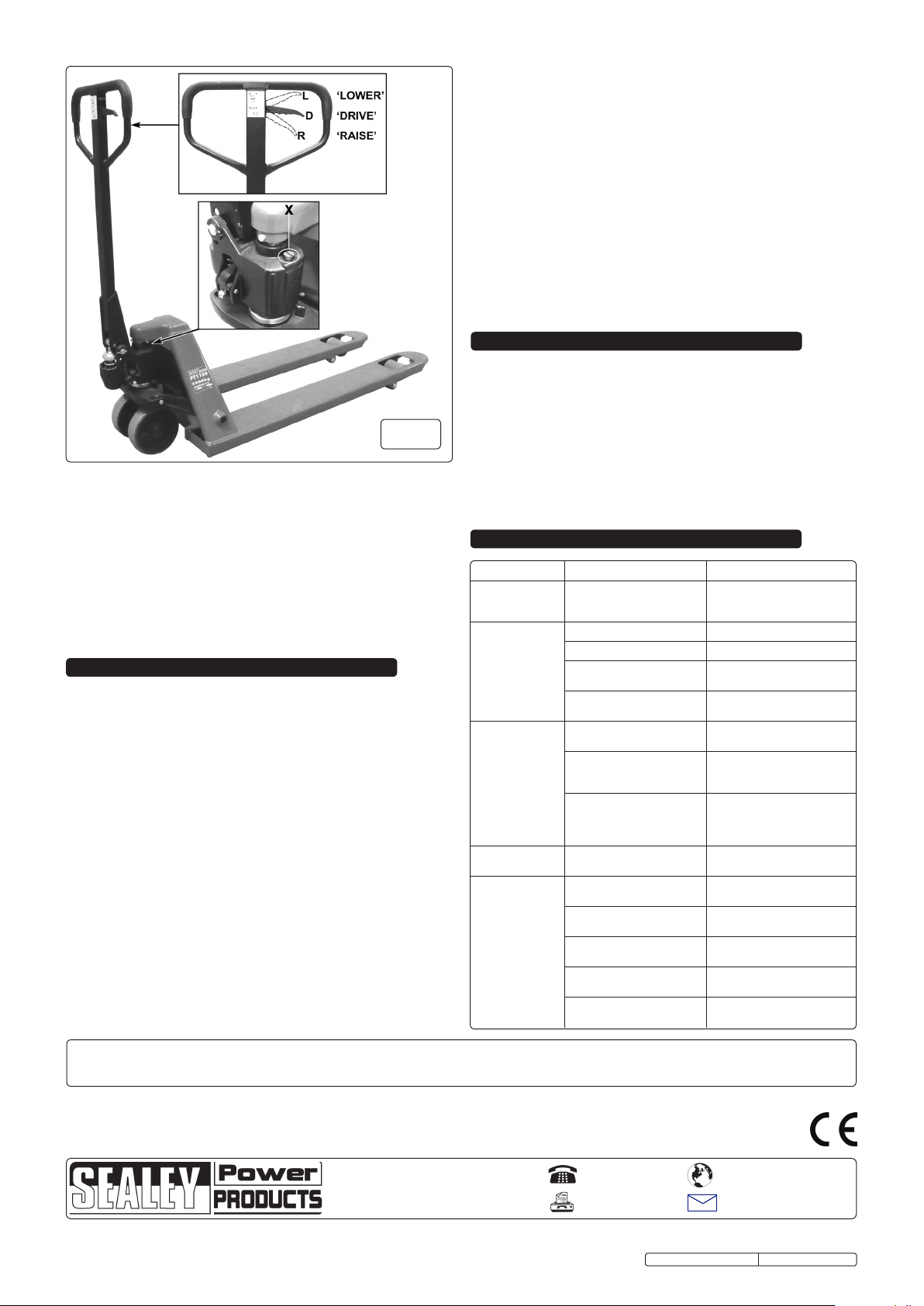

3.5 Referring to the inset cross section in fig.1, Insert the chain (2)

with adjusting bolt (6) and nut (8) attached through the hole in

the centre of the pivot pin.

3.6 There is a transit pin just below the main handle pivot which

needs to be removed. Lower the handle down so that the

rolling sleeve (3) bears down on top of the piston and remove

the transit pin.

3.7 Move the lever control at the top of the handle into it's lowest

position. Then raise the rocking lever plate (7) which sits within

the main casting and move the chain adjusting bolt (6) into the

slot in the end of the plate so that the adjusting nut (8) is now

underneath the plate as shown on the inset cross section in fig.1.

3.1 Identify the handle pivot pin (5) and tap a roll pin (9) through

one end of it so that it sticks out equally either side.

3.2 Position yourself behind the truck and insert the handle

assembly into the pump casting (see fig.1). Align the pivot

holes at the base of the handle with the pivot holes in the

casting. Take the pivot pin and orientate it so that the inserted

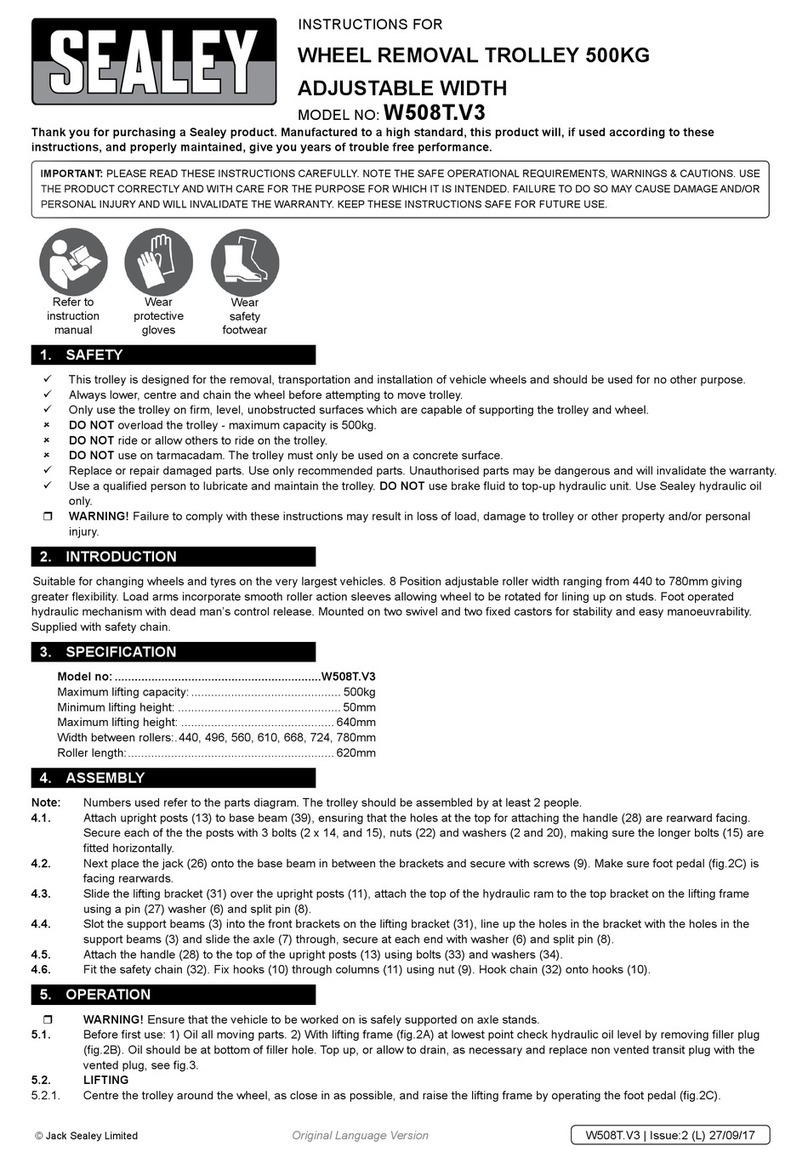

4. ADJUSTMENTS

4.1 The control lever (see fig.2) has three positions as follows:-

RAISE - Lever in lowest position.

DRIVE - Lever in centre position.

LOWER - Lever held in up position. When released the lever

returns to the drive position.

4.2 If the lever does not work in the prescribed way it can be

adjusted using the nut (8) at the bottom of the adjusting rod

(6) which is attached to the chain (2). See fig.1.

4.3 If the truck elevates whilst pumping in the Drive position, turn

the adjusting nut clockwise until the pumping action no longer

raises the truck and the Drive functions correctly.

Original Language Version

fig.1

PT1150.V2 & PT1220.V2 Issue No.1 - 00/00/00