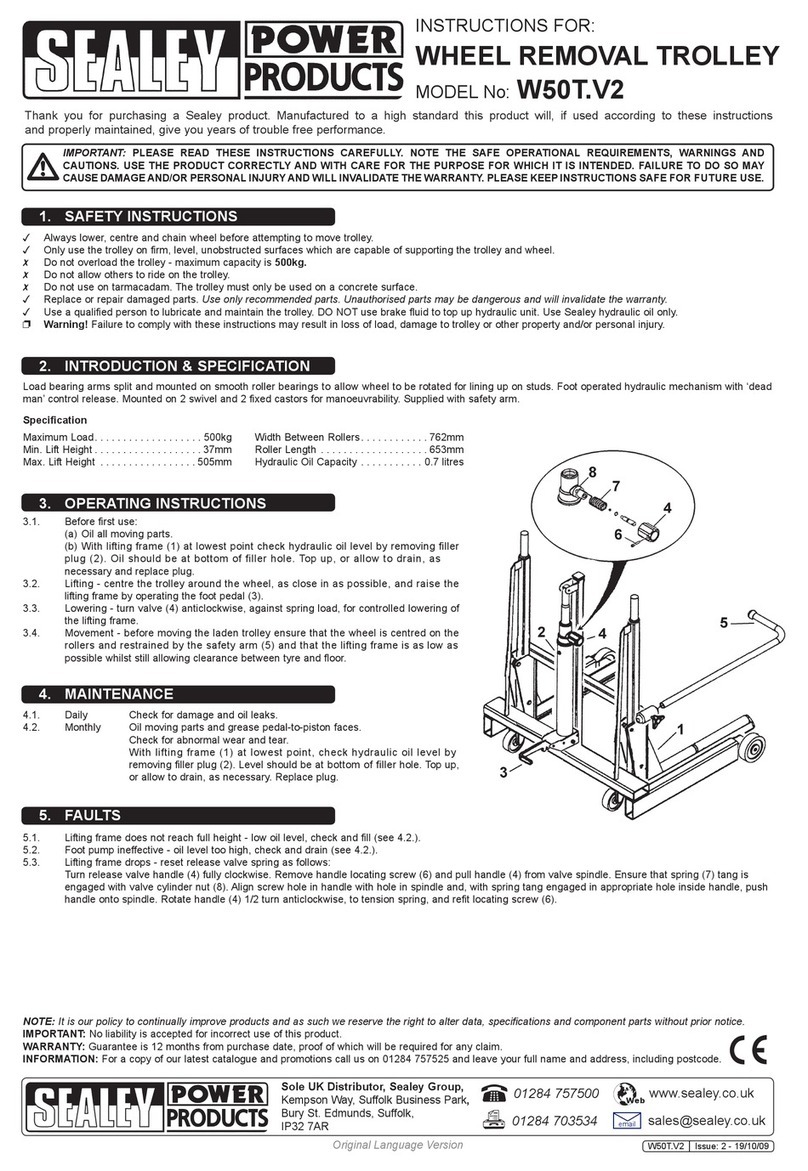

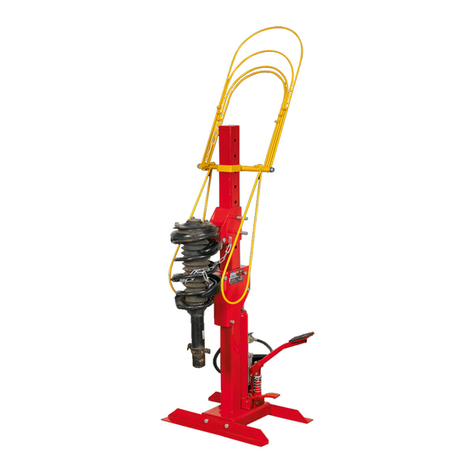

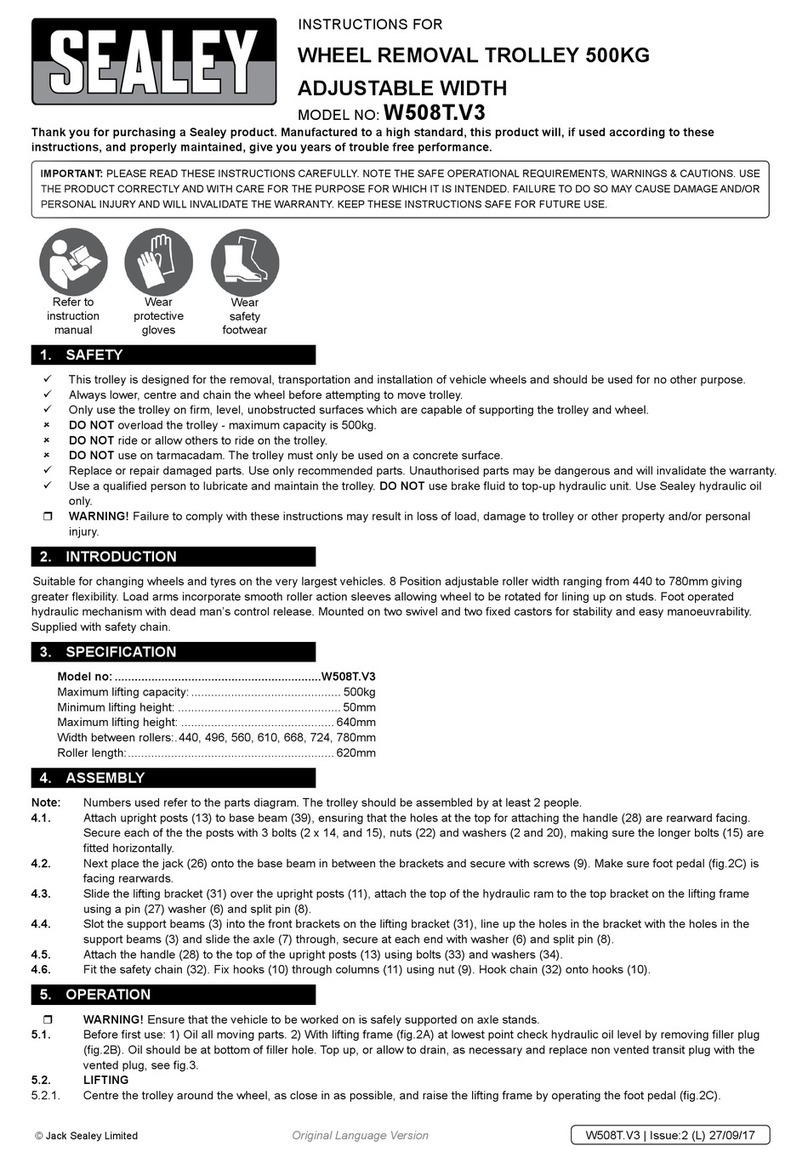

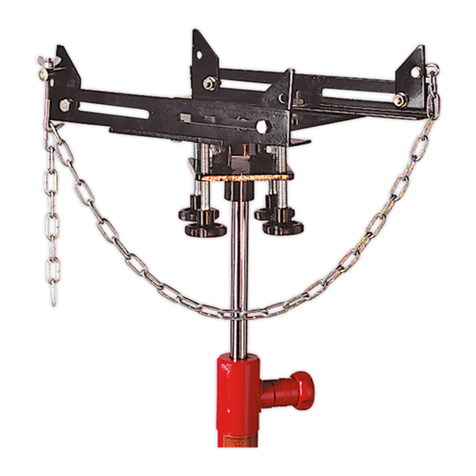

MOTORCYCLE FORK SPRING COMPRESSOR

MODEL NO: MS1824.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

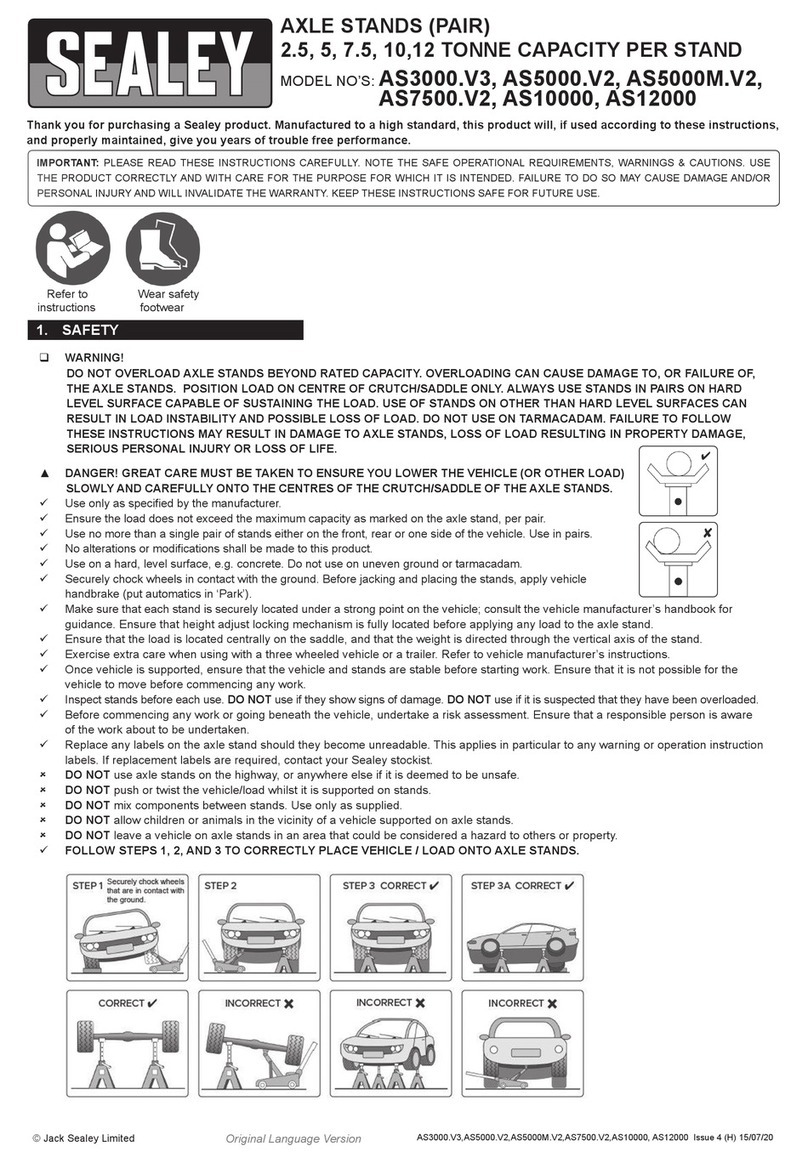

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

9Before each use, check the unit for full functional capability. If the functional capability is not ensured or if damage is detected, the unit

should not be used and you should contact your supplier immediately.

WARNING! Wear approved safety eye protection (standard spectacles are not adequate) and protective gloves.

WARNING! DO NOT compress the spring to an extent where the jaws touch.

8DO NOT use the compressor for other purposes than it was designed for and DO NOT OVERLOAD the compressor.

8DO NOT operate spring compressor if parts are damaged or missing as this may cause failure and/or personal injury.

9Maintain the spring compressor in good condition. Replacement or repair of damaged parts must be carried out by competent

personnel. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

8DO NOT force the spring compressor to achieve a task it was not designed to perform.

8DO NOT allow untrained persons to use the spring compressor.

9Familiarise yourself with the applications, limitations and potential hazards of the spring compressor.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Keep hands and body clear of the spring when operating the spring compressor.

9 Maintaincorrectbalanceandfooting.Ensuretheoorisnotslipperyandwearnon-slipshoes.

9 Removeillttingclothes.Removeties,watches,rings,otherloosejewellery.Containand/ortiebacklonghair.

9For indoor use and at room temperature only.

9When not in use clean and store the spring compressor in a safe, dry, childproof location.

2. INTRODUCTION

Designedtorelieveforkspringtensionallowingremovalofthetubecapsfromtherod,withoutdamagingthethreads.Canbeusedwiththefork

in situ or on the bench. Use with 17mm socket.

3. SPECIFICATION

Model no ............................................................. MS1824.V2

Maximum reach ......................................................... 750mm

Maximum fork tube diameter..................................... Ø32mm

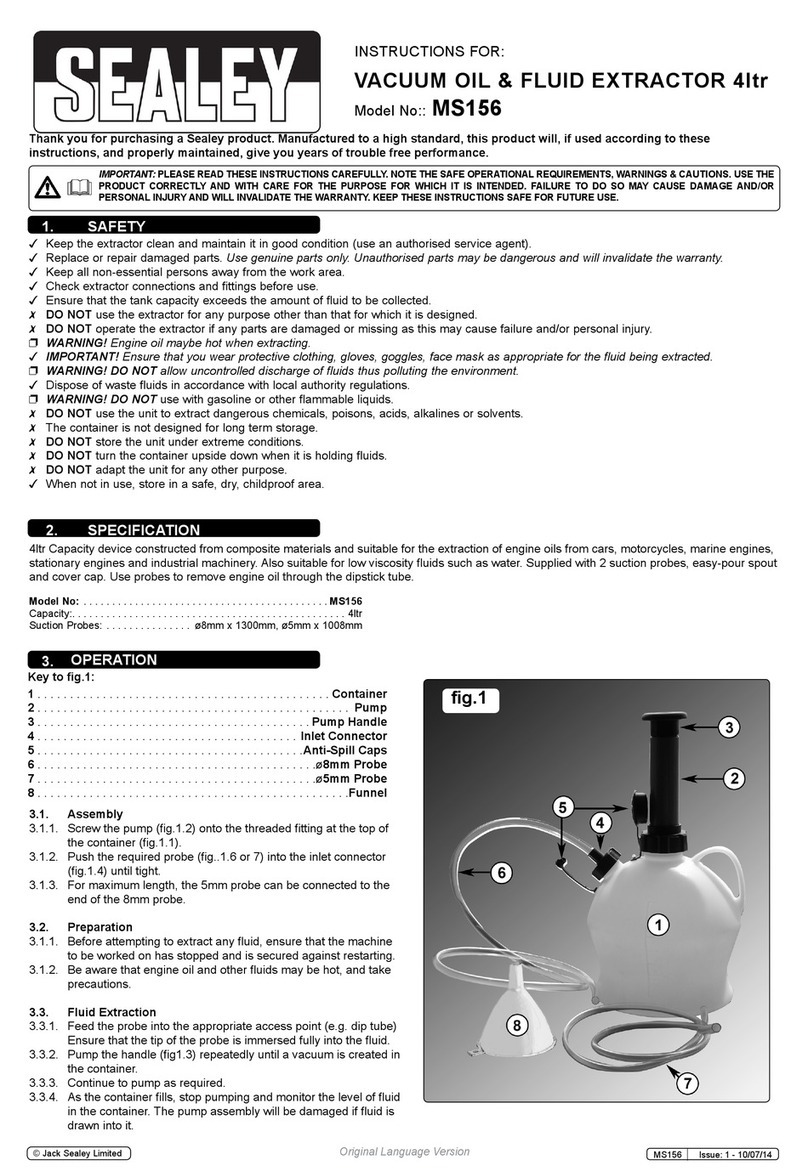

4. OPERATION

NOTE: Always refer to the original manufacturer’s manual for assembly and dismantling of motorcycle forks.

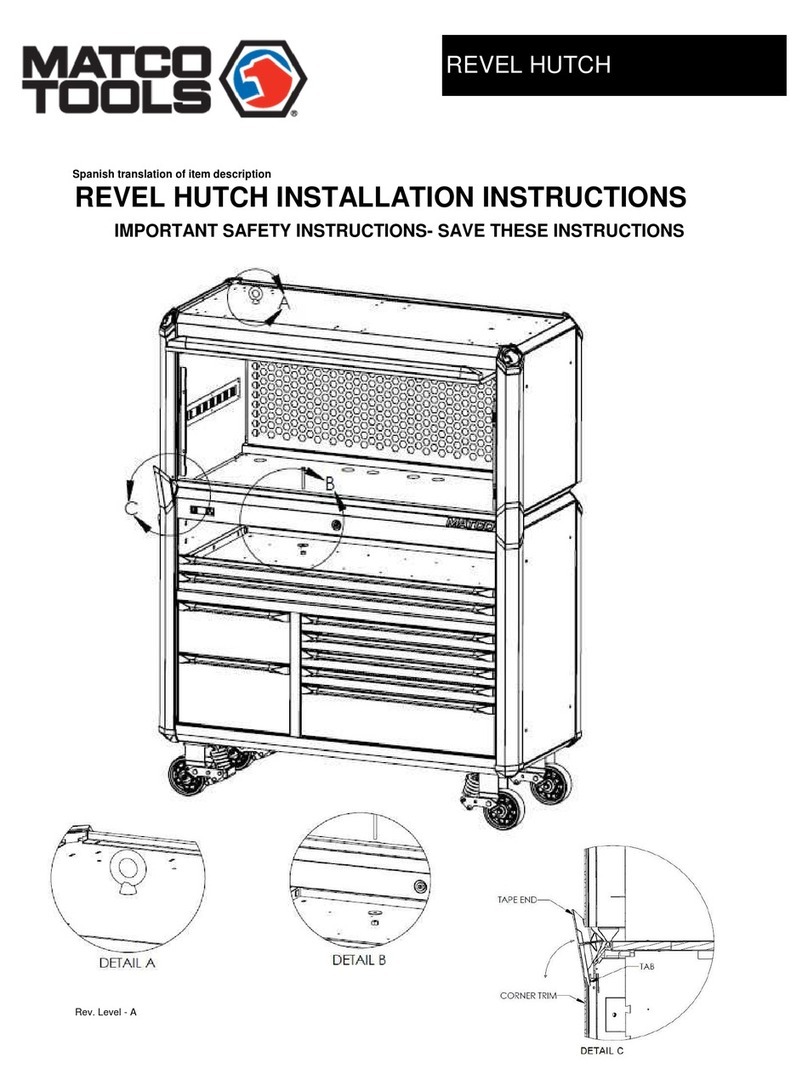

4.1. Clamptheforkspringcompressorhorizontallyorverticallyinaviceusingtheutilitybracket.

4.2. Adjust the fork spring compressor length to suit the fork length approximately.

4.3. Remove the nut at the top of the fork.

4.4. Locate the bottom of the fork on the compressor pin.

4.5. The two screws on the tool are to align with the two holes in the fork internal sleeve. The fork internal sleeve is an aluminium alloy;

location of the screws and holes is required only. DO NOT apply force to the internal sleeve when locating.

4.6. Using a 17mm socket, tighten the tool pulling down the collar and the spring, which allows access to the nut holding the fork cap in

place.

Refer to

instruction

manual

Wear eye

protection Wear protective

gloves

Original Language Version

© Jack Sealey Limited MS1824.V2 | Issue:2 (H,F) 19/09/19