INSTRUCTIONS FOR

SERVICE INDICATOR & EPB RESET TOOL -

LAND ROVER / RANGE ROVER

MODEL NO: VS8624

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure that Health and Safety, local authority and general workshop practice regulations are

strictly adhered to.

8DO NOT use the unit if it, or any attachment, is damaged.

9Maintain tester in good and clean condition for best and safest performance.

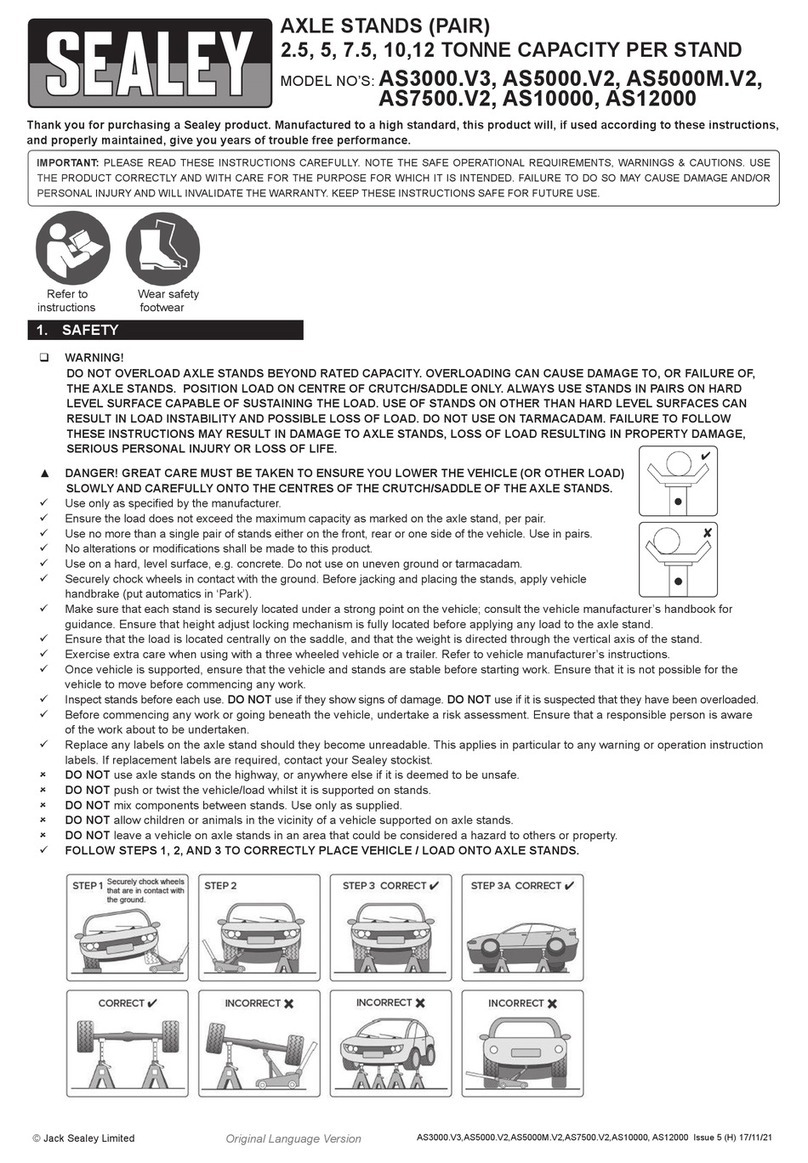

9If required, ensure that the vehicle to be worked on is adequately supported with axle stands or ramps and is chocked.

9Put transmission in PARK (for automatic transmission) or NEUTRAL (for manual transmission) and make sure the parking brake is

engaged, or wheel chocks are in place.

9Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

9Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

WARNING! Use extreme caution when working around the ignition coil, distributor cap, ignition wires and spark plugs. These

components create hazardous voltages when the engine is running.

8DO NOT connect or disconnect any test equipment with ignition on or engine running.

9Keep a re extinguisher nearby, which is suitable for gasoline/chemical/electrical res.

9Account for all tools and parts being used and do not leave any in the engine bay.

9Keep reset tool dry, clean and free from oil, water and grease. Use a mild detergent on a clean cloth to clean the outside of the tool.

9Operate the vehicle in a well-ventilated work area; exhaust gases are poisonous.

IMPORTANT: Always refer to the vehicle manufacturer’s service instructions to establish the current procedure and data.

These instructions are provided as a guide only.

WARNING! The warnings and instructions discussed in this manual cannot cover all possible conditions and situations that may occur.

It must be understood that common sense and caution are factors which cannot be built into this product, but must be applied by the

operator.

2. INTRODUCTION

Essential tool for extinguishing the service indicator and resetting Electronic

Parking Brake on Land Rover and Range Rover vehicles. Simple push button

operation allows EPB cable to be released and re-attached and, in the event

that the emergency hand brake has been activated, allows the user to reset

the system, and clears codes that may have been generated as a result of the

emergency cable being pulled. It also allows the EPB to be un-jammed when

the vehicle has entered a state of brake screech when applying the parking

brake, where the rear brakes squeak or rub when the vehicle is moving or

there is evidence of shoe-drag. Powered by connection to the vehicle.

3. OPERATION

3.1. The VS8624 tool:

• is compatible with the latest CAN vehicles.

• enables Service and Inspection mode for safe working practices.

• is updateable.

3.2. The VS8624 Land Rover/ Range Rover Service Indicator

Reset and Electronic Park Brake (EPB) tool has been designed to

extinguish service indicators and to mount the cable for the EPB for

Land Rovers and Range Rovers. In addition, it will also allow the resetting of

the EPB system if the emergency release cable has been activated, and to

release the EPB in the event that it has become jammed.

3.3. Service Function:

Service Reset – Will reset the service indicator on the vehicle.

• 24,000km / 15,000 miles / 12 months

• 12,000km / 7,500 miles / 6 months

Original Language Version

© Jack Sealey Limited

Refer to

Instructions

Electrical

Shock

Hazard

Wear Eye

Protection

Wear Protective

Clothing

VS8624 | Issue 2 01/07/16