Original Language Version

© Jack Sealey Limited

4. OPERATION

4.1. PREPARATION

4.1.1. Ensure that the area where the vehicle is to be moved is clear of any obstructions. The oor surface should be smooth and level.

4.1.2. Take note of any features in the oor, that may catch the skate wheels or cause damage to the oor surface, such as oor mounted

power and data points, room divider tracks, drainage features etc.

4.1.3. Enlist sufcient manpower to move the vehicle safely. DO NOT attempt to move the vehicle into an area where there is insufcient

space to manoeuvre the vehicle safely.

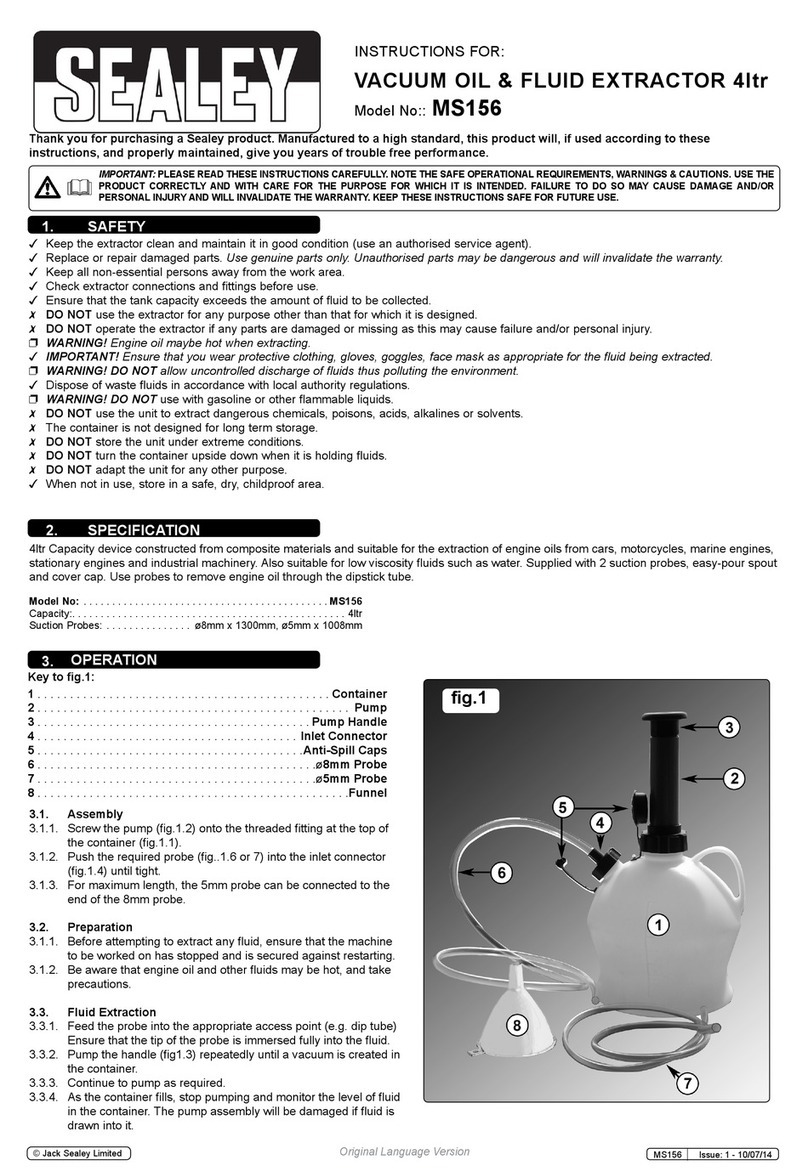

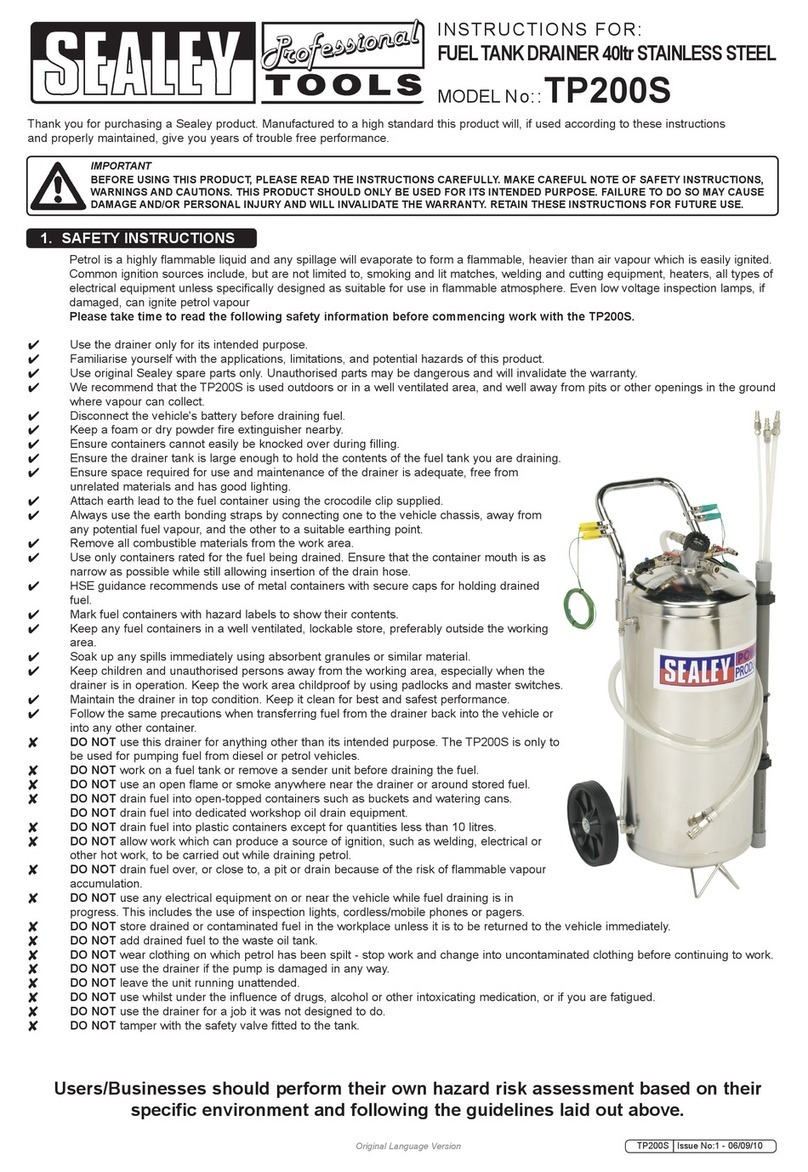

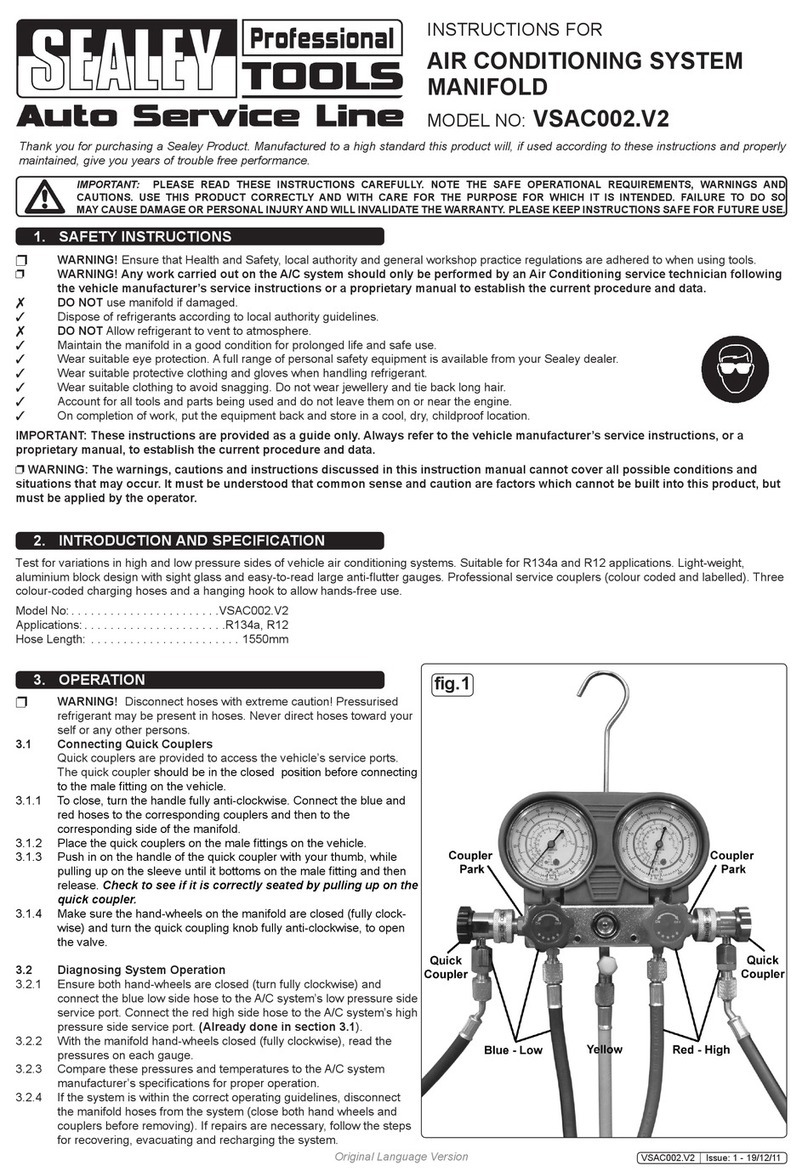

4.1.4. Prior to operation, release the foot pedal from the transit hook by depressing the pedal slightly and moving the hook to one side to

allow the pedal to rise up (g.1).

4.1.5. Wheel Skates must be used as a pair. Attach to the front wheels to swing the front of the vehicle. DO NOT release the hand-brake or

remove wheel chocks until both Skates are attached. Re-engage hand-brake or chock the wheels immediately after any

movement has been made. Attach to rear wheels to swing the rear of the vehicle (ideally front wheels should be straight). If it

is intended to use two pairs of skates to move a vehicle in one movement, great care should be exercised in order to avoid injury to

persons or property.

Refer to Section 1 before using the wheel skate.

IMPORTANT: BEFORE FIRST USING THE SKATE, PURGE ANY AIR FROM THE HYDRAULIC CIRCUIT.

4.1.6. Purging the hydraulic circuit eliminates any air that may have accumulated in the system during transit, to purge the circuit:

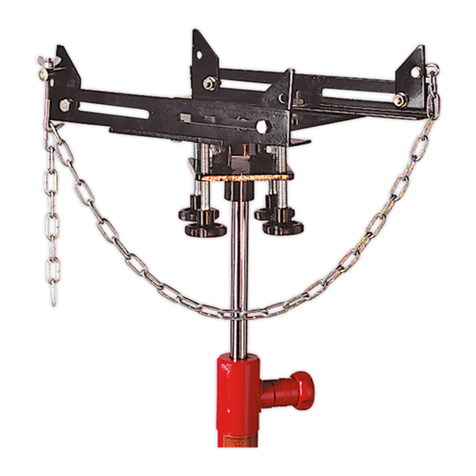

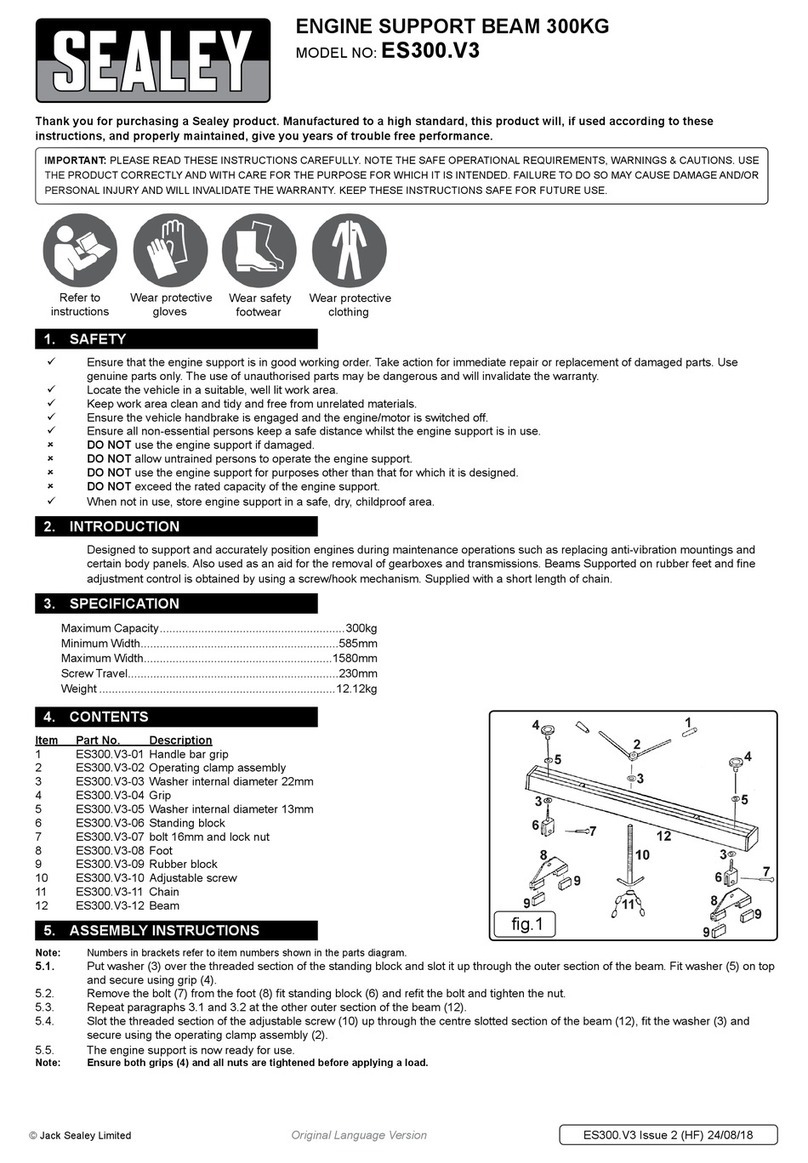

a. Open the release valve by turning it (fig.2) anti-clockwise.

b. Pump the pedal up and down 15 to 20 times.

c. Turn the release valve clockwise to close the valve.

4.2. OPERATION

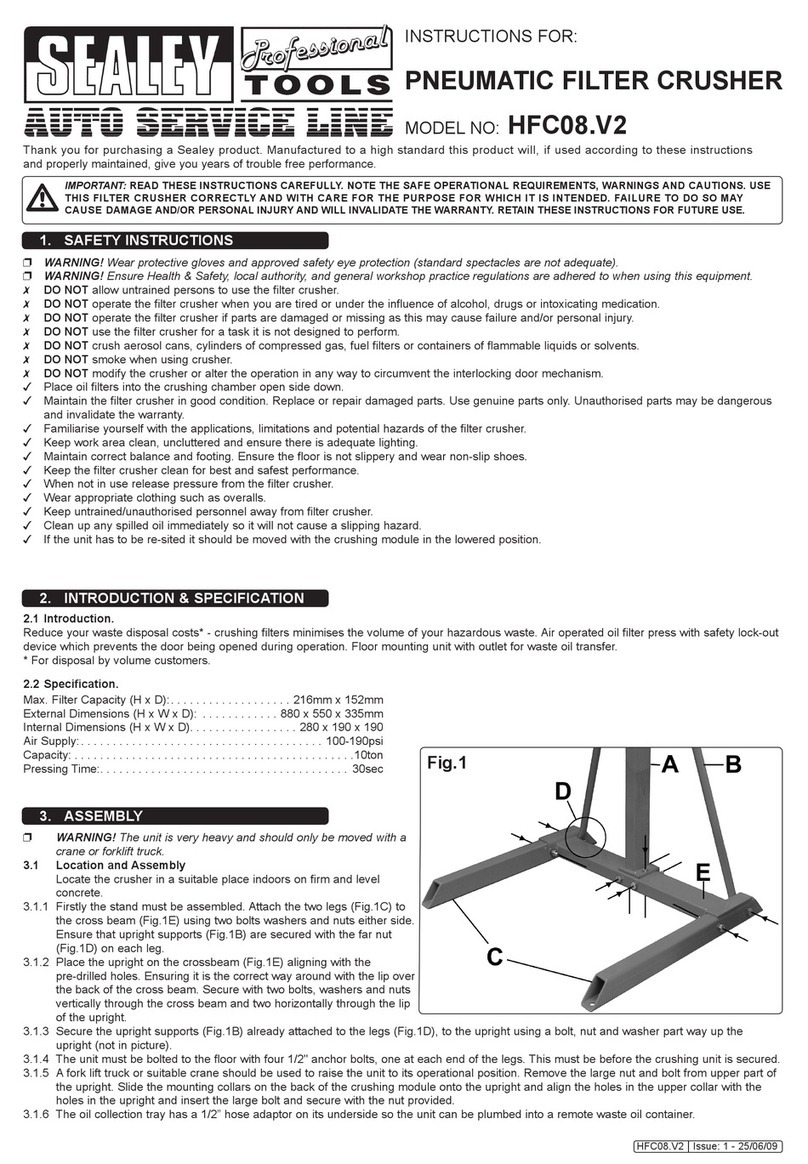

4.2.1. To t a Skate to a wheel you must rst turn the release valve anti-clockwise (g.2) and remove the locking pin (g.3).

4.3. POSITIONING THE SKATE

Take hold of each side of the frame and expand the unit until it is wide enough to slide the rollers either side of the tyre. Make sure that

both sets of rollers are centred on the tyre.

4.4. RAISING A WHEEL

4.4.1. Now close the release valve by turning clockwise (g.2).

4.4.2. Operate the foot pedal lever to commence raising the wheel. (IMPORTANT - Allow the pedal to return through its full travel before

commencing the next stroke.) Continue until the tyre is clear of the ground and you are able to insert the locking pin as shown in fig.3.

4.4.3. Raise the second wheel off the ground with the other Skate. Be prepared for any movement the vehicle may make when the second

wheel becomes clear of the ground. This is particularly important when using four skates. Providing the ground/floor is level the vehicle

should remain stable (read safety precautions in Section 1).

4.5. MOVING THE VEHICLE

4.5.1. Ensure that you have sufficient manpower to move and control the vehicle. Keep well away from any sloping areas or entry ramps to the

area, however shallow they may appear. When positioning a vehicle in relation to a wall or feature such as a pillar, no persons or objects

should be situated between the vehicle and the feature. Sufficient space should be left between the side of a vehicle and an adjacent

wall or feature to allow the Skates to be withdrawn sideways.

4.6. LOWERING WHEELS

4.6.1. Remove the locking pin and slowly turn the release valve anti-clockwise to lower the vehicle until the tyre is on the ground and no longer

exerting pressure on the rollers.

Beware of sudden movement of the unit components as the vehicle is lowered. Keep hands and feet away from any potential pinch-

points.

4.7. REMOVING THE SKATE

4.7.1. Expand the unit sufficiently to clear the tyre and move it away from the wheel.

5. MAINTENANCE

5.1. Periodically lubricate the wheels, rollers and the foot pedal lever pivot with oil. Lightly grease the four faces of the square section tube.

5.2. When the skate is not in use, store fully closed with the locking pin in place, this will minimise ram and piston corrosion.

5.3. Before each use, ensure all components are in good working order. If any suspect item is found, remove skate from service and take

necessary action to remedy the problem.

8DO NOT use the skate if you believe it has been subjected to an abnormal or shock load. If in doubt contact your local service

agent.

IMPORTANT: All other maintenance and repair (including oil change) must only be undertaken by fully qualied personnel. Contact

your local authorised service agent.

5.4. The oil cylinder is a sealed unit and should not be accessed. To top up oil, remove oil plug on ram and fill to just below oil plug hole.

WARNING! Only a good quality hydraulic Jack oil, such as SEALEY HYDRAULIC JACK OIL must be used, DO NOT use brake

fluid. DO NOT overfill as this will render the skate inoperative.

fig.2fig.1

fig.3

WS650.V3 Issue 2 (3) 04/11/19