Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

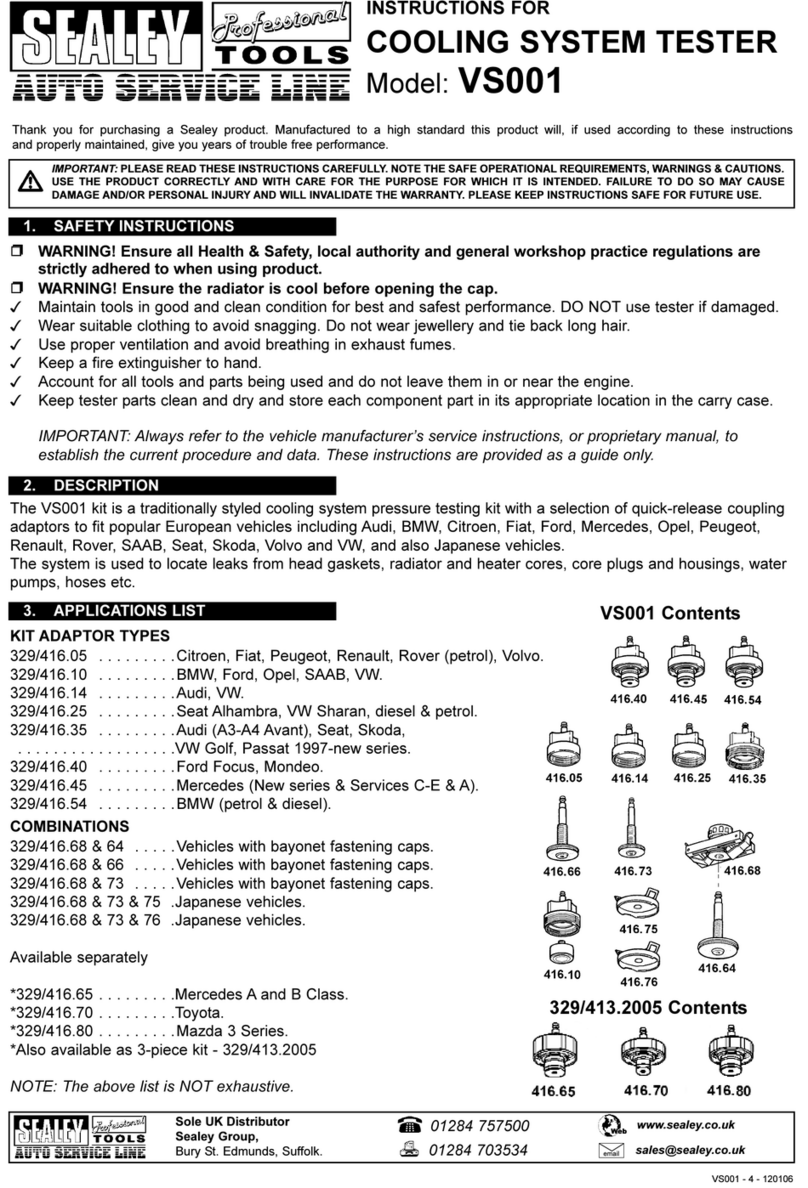

3. PARTS

2. INTRODUCTION

WARNING! Ensure Health and Safety, local authority and general workshop practice regulations are adhered to when using this kit.

WARNING! Fuel is flammable - keep away from sources of ignition, including hot surfaces e.g. exhaust manifold.

DO NOT use the kit if any parts are missing or damaged.

DO NOT use the kit to perform a task for which it is not designed.

DO NOT allow untrained persons to use the kit.

DO NOT use when tired or under the influence of drugs, alcohol or intoxicating medication.

Switch off vehicle's ignition before commencing work under the bonnet.

Maintain the kit's components in good and clean condition for best and safest performance.

Wear eye protection and keep skin contact with fuel to a minimum. If fuel enters eyes rinse with plenty of water and seek medical

advice. If swallowed seek medical advice immediately. A full range of personal safety equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

Keep children and other unauthorised persons away from the working area.

Ensure there is adequate lighting whilst using this kit.

Use approved parts only. Unapproved parts may be dangerous and will invalidate the warranty.

Keep work area clean and tidy and free from unrelated materials.

If running the vehicle's engine in an enclosed space, ensure that there is sufficient ventilation or use an exhaust extraction system.

Dispose of waste fuel in accordance with local authority regulations.

When work on the vehicle is finished ensure that there are no tools or parts left in the engine compartment.

After use, clean equipment, return all contents to the case and store in a safe, dry, childproof location.

IMPORTANT: Always refer to the vehicle manufacturer's service instructions, or proprietary manual, to establish the current

procedures and

correct data.

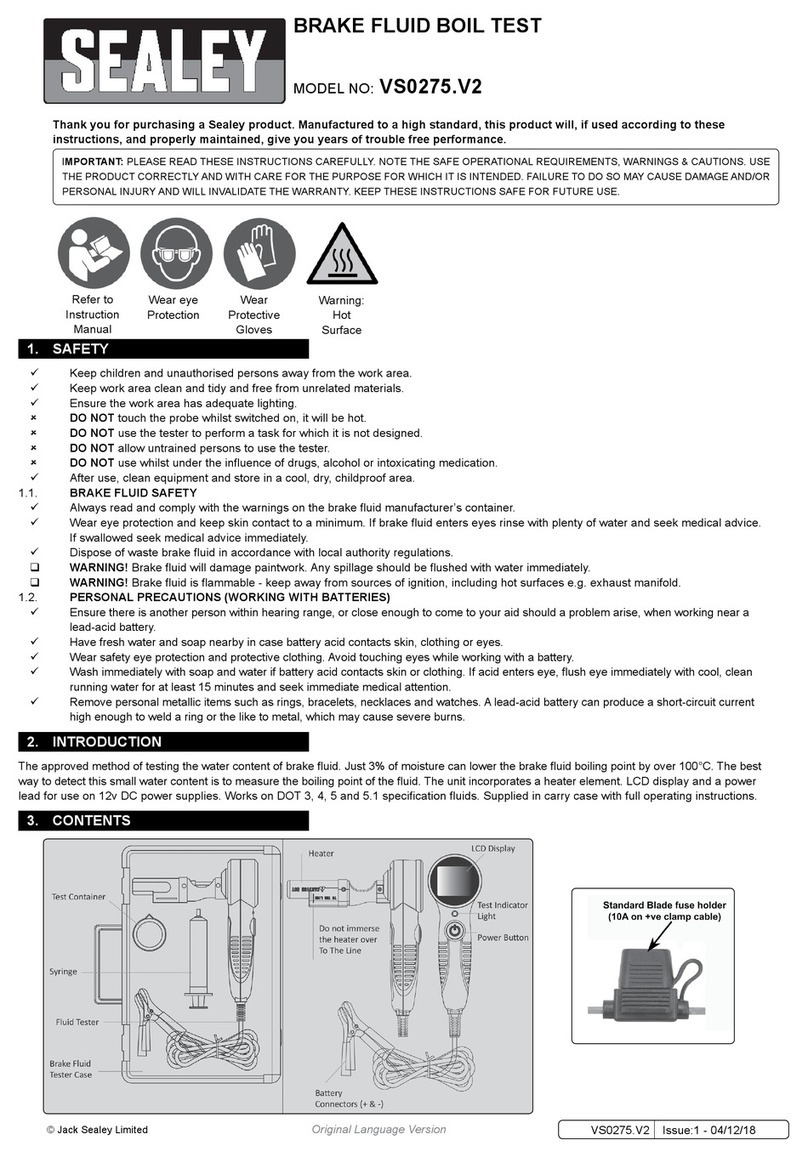

Item Part No. Description

1 VS2050.V2.01 Pressure Gauge (-1 to +3 bar) (Delphi)

2 VS2050.V2.02 Pressure Gauge (-1 to +15 bar) (Bosch/Siemens)

3 VS2050.V2.03 Main Body

4 VS2050.V2.04 Injector Connector

5 VS2050.V2.05 Injector Connector (angled)

Item Part No. Description

6 VS2050.V2.06 Brass Cone (Delphi)

7 VS2050.V2.07 Return Flow Connector (Brass end)

8 VS2050.V2.08 Return Flow Connector

9 VS2050.V2.09 Drain Tube (Delphi-brass cone)

10 VS2050.V2.10 Drain Tube (Delphi-brass cone)

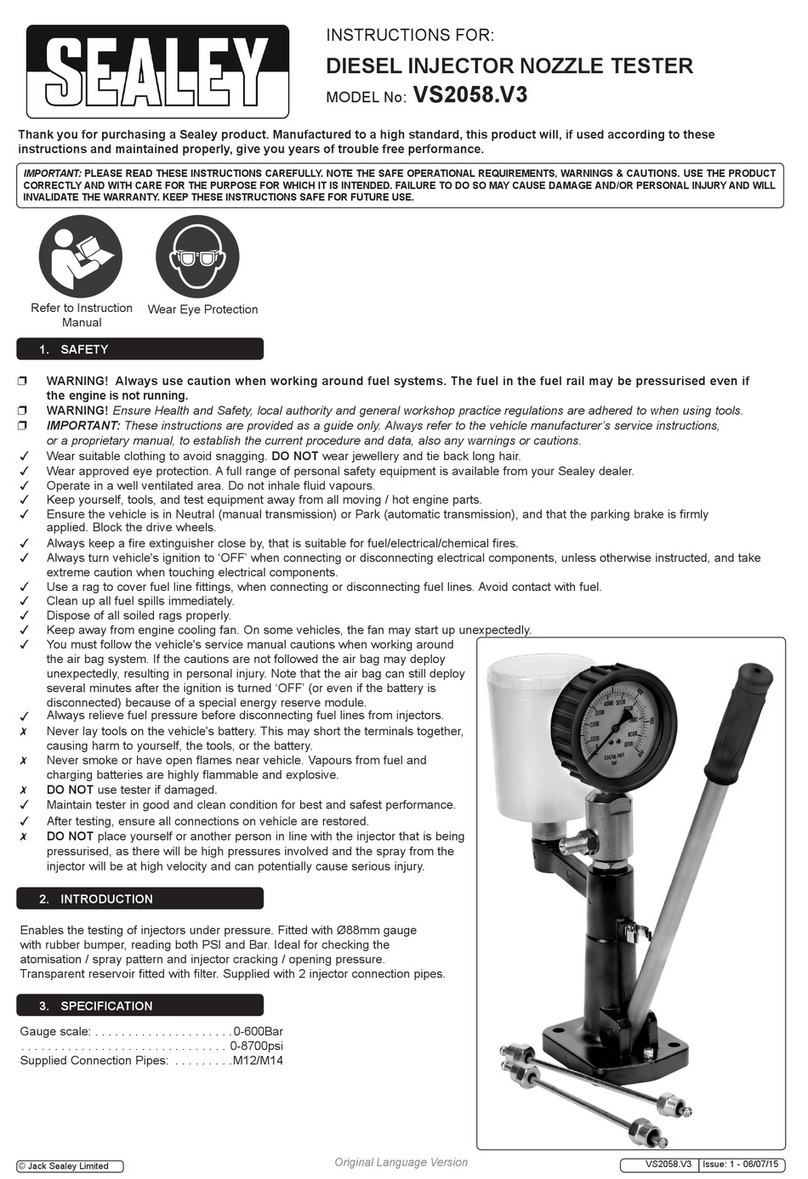

Specially designed to test the return fuel flow pressure from Piezo diesel common rail injectors on Bosch, Delphi and Siemens systems. Supplied

with two gauges, -1 to +3 bar and -1 to +15 bar. Sight-glass that identifies air in the fuel system and drain valve allows safe recovery of fuel.

Drain Pipe Drain Valve

Main

Tester

Body

3

INSTRUCTIONS FOR:

DIESEL INJECTION LEAK BACK

TEST KIT - PIEZO

MODEL No: VS2050.V2

Original Language Version VS2050.V2 Issue: 1 - 30/10/13

©Jack Sealey Limited