INSTRUCTIONS FOR

PROFESSIONAL BATTERY DROP TESTER 6/12V -

POLARITY FREE

MODEL NO: BT91/7PF

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

DANGER! BE AWARE, LEAD-ACID BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS

REASON, IT IS VERY IMPORTANT TO READ AND FOLLOW THESE INSTRUCTIONS CAREFULLY, EACH TIME YOU USE THE

BATTERY TESTER.

Follow these instructions and those published by the battery and vehicle manufacturers, and the maker of any equipment you intend to use

in the vicinity of the battery. Remember to review warning marks on all products and on engines.

1.1. PERSONAL PRECAUTIONS

9Ensure there is another person within hearing range of your voice and close enough to come to your aid, should a problem arise when

working near a lead-acid battery.

9Wear safety eye protection and protective clothing. Avoid touching eyes while working near battery.

9Have fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

9Wash immediately with soap and water if battery acid contacts skin or clothing. If acid enters eye, flush eye immediately with cool, clean

running water for at least 15 minutes and seek immediate medical attention.

9Remove personal metallic items such as rings, bracelets, necklaces and watches. A lead-acid battery can produce a short-circuit current

which is high enough to weld a ring or the like to metal, which would cause severe burns.

9Ensure hands, clothing (especially belts) are clear of fan blades and other moving or hot parts of engine, remove ties and contain long

hair.

8DO NOT smoke or allow a spark or flame in the vicinity of battery or engine.

1.2.

GENERAL SAFETY INSTRUCTIONS

9Familiarise yourself with the application and limitations of the tester as well as the potential hazards.Also refer to the vehicle manufacturer’s

hand book.

9IF IN ANY DOUBT CONSULT AN ELECTRICIAN.

9Ensure the tester is in good order and condition before use. If in any doubt do not use the unit and contact an electrician.

9Only use recommended attachments and parts. To use non-recommended items may be dangerous and will invalidate your warranty.

9Ensure the tester load switch is ‘Off’ before attaching/detaching the power clamps to/from the battery terminals.

9Keep tools and other items away from the engine and ensure you can see the battery and working parts of engine clearly.

9Confirm that the battery to be tested is 6 or 12 volt and not 24 volt before attaching clamps to battery terminals.

9If the tester receives a sharp knock or blow the unit must be checked by a qualified service agent before using.

9If the battery terminals are corroded or dirty clean them before attaching the clamps.

9Keep children and unauthorised persons away from the working area.

8DO NOT dis-assemble the tester for any reason. The tester must only be checked by qualified service personnel.

WARNING! To prevent the risk of sparking, short circuit and possible explosion DO NOT drop metal tools in the battery area, or allow them to

touch the battery terminals.

8DO NOT pull the cables or clamps from the battery terminals.

8DO NOT use the tester in damp, or wet locations and DO NOT use within the vicinity of flammable liquids or gases.

9Ensure there is effective ventilation to prevent a build-up of explosive gases, and do not cover or obstruct tester ventilation louvres.

8DO NOT use the tester for a task for which it is not designed.

9When not in use, store the tester carefully in a safe, dry, childproof location.

8

DO NOT operate the load switch for more than 10 seconds at a time. (Failure to release the switch after 10 seconds may result in the

switch burning out and invalidating your warranty.)

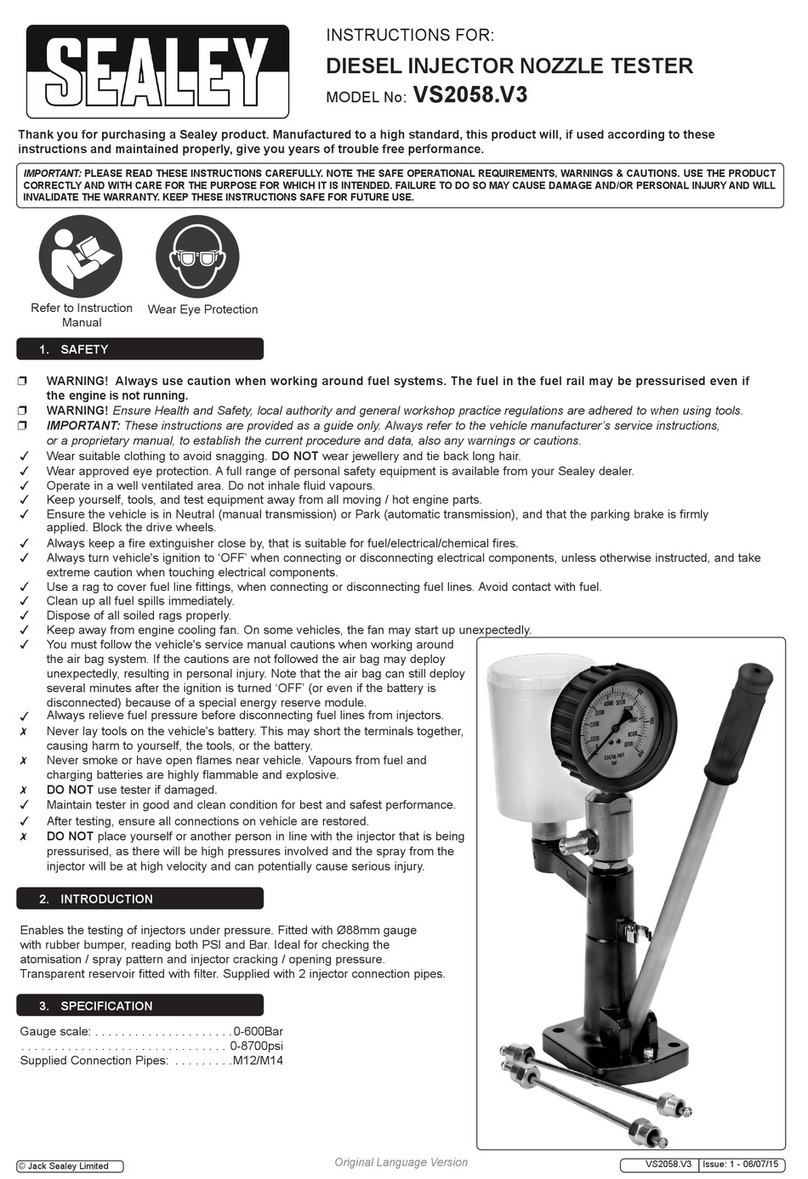

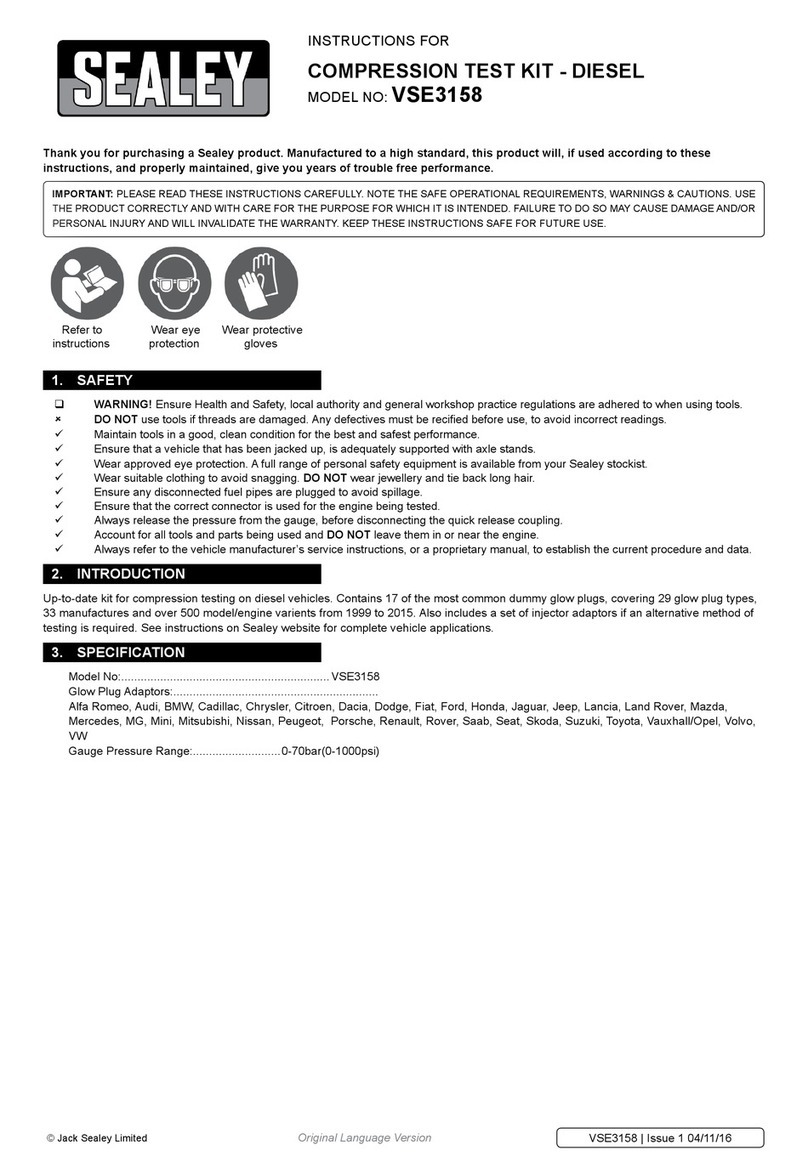

2. INTRODUCTION

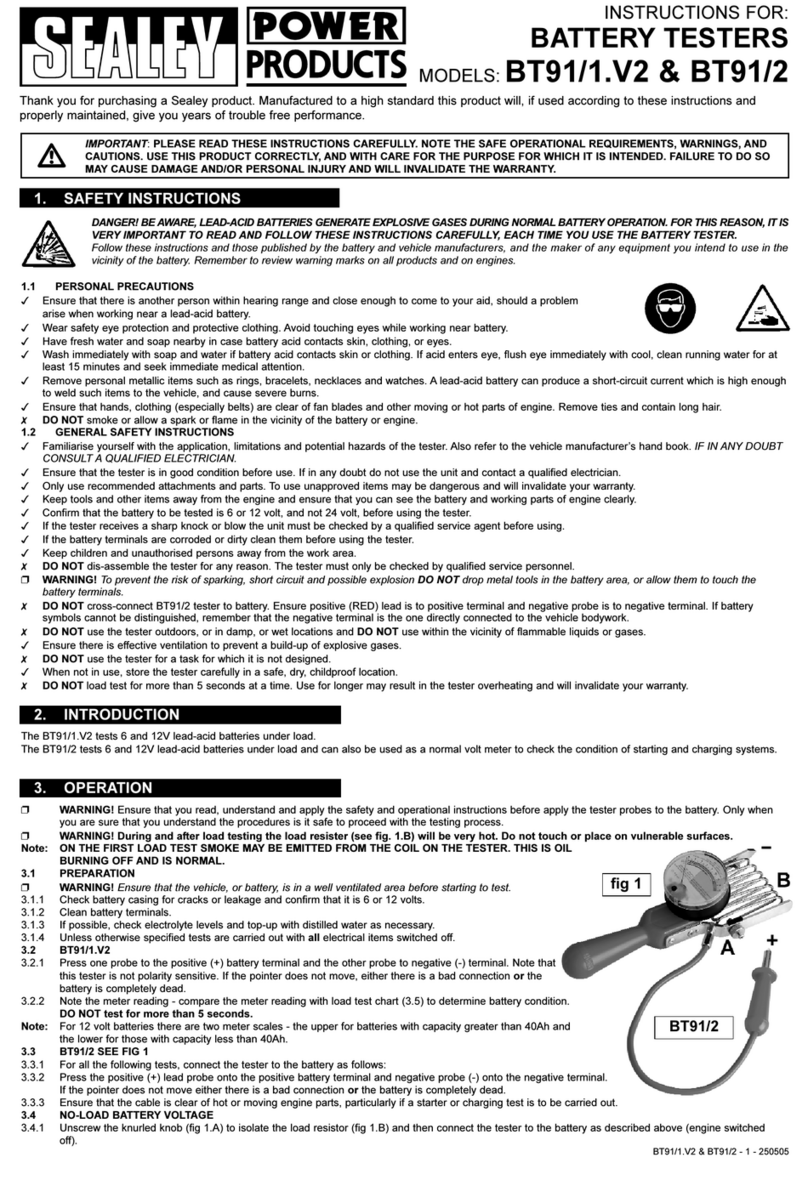

American pattern drop tester. Polarity protected cables - impossible to damage unit by misconnection. Load applied by internal switchgear - no

sparking! Suitable for 6 and 12Volt batteries. Applies load across cells and measures output on meter. Accurate indication of battery voltage, faulty

cell and short circuited cell.

BT91/7PF | Issue 2(L) 26/02/16

Original Language Version

© Jack Sealey Limited

Refer to

Instructions

Wear eye

Protection

Wear

Protective

Clothing

Warning:

Explosive

Material

Warning:

Corrosive

material

No open

ames

Wear

Protective

Gloves

Battery:

Ventilate area