3. OPERATING INSTRUCTIONS

WARNING! Ensure Health & Safety, local

authority and general workshop practice

requirements are adhered to when using this

equipment. Familiarise yourself with the

application and limitations, as well as the potential

hazards of the set.

This set is suitable for steel pipe.

Maintain the set in good condition.

Replace or repair damaged parts. Use genuine

parts only. Unauthorised parts may be dangerous

and will invalidate the warranty.

Locate the flaring set in a suitable work area,

keep the area clean and tidy and ensure there is

adequate lighting.

WARNING! Always wear approved eye or face

protection when using the flaring tools.

Keep children and unauthorised persons away

from the working area.

DO NOT use the set for any purpose other than

for which it is designed.

DO NOT use the set if any parts are damaged or

missing as this may cause failure and/or

personal injury.

DO NOT allow untrained persons to use the set.

DO NOT attempt to flare piping when you are

tired, under the influence of alcohol, drugs or

intoxicating medication.

When not in use clean set components, replace

in case and store in a safe, dry, childproof area.

Remember! The safe operation of a vehicle, or

other equipment, may well depend on the quality

of the flare produced. Discard any flare which is

mis-formed.

WARNING! The warnings, cautions and

instructions discussed in this manual cannot cover

all possible conditions and situations that may

occur. It must be understood that common sense

and caution are factors which cannot be built into

this product, but must be applied by the operator.

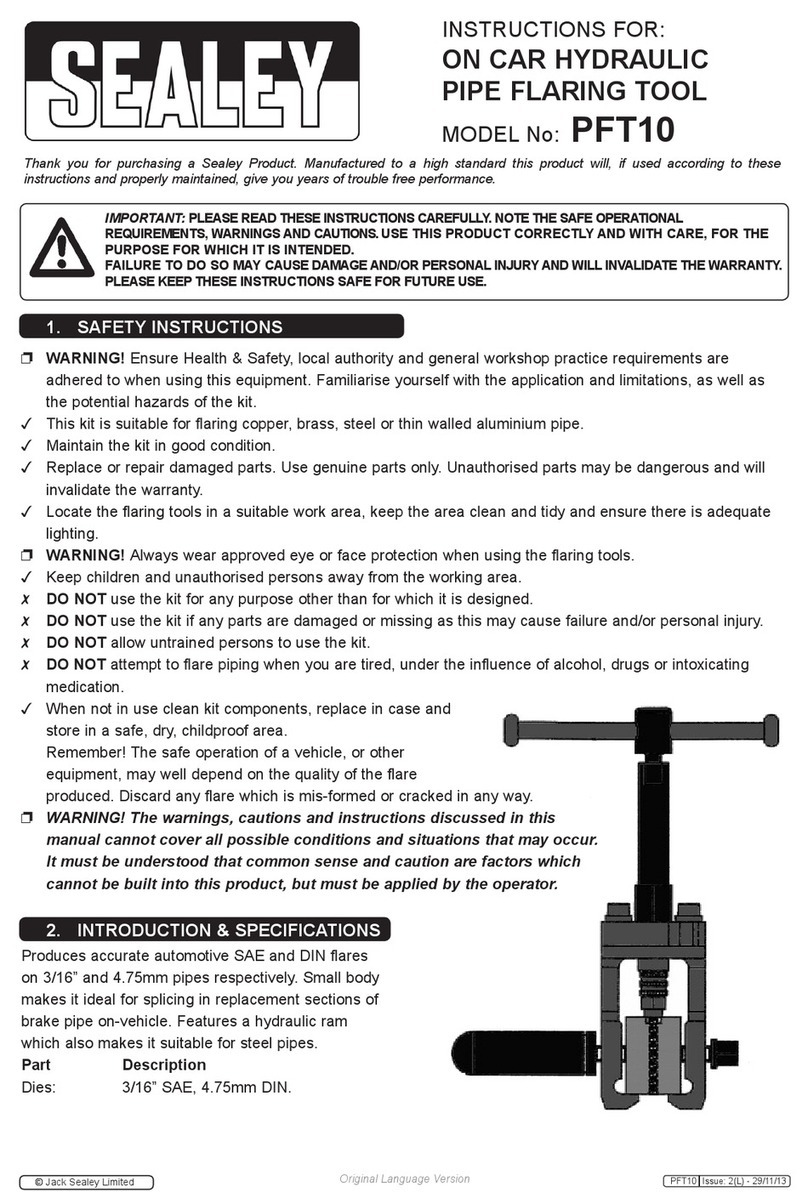

INSTRUCTIONS FOR:

ON-VEHICLE MICRO PIPE FLARING

TOOL

MODEL No: PFT12

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according

to these instructions and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE, FOR THE PURPOSE FOR

WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. PLEASE KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

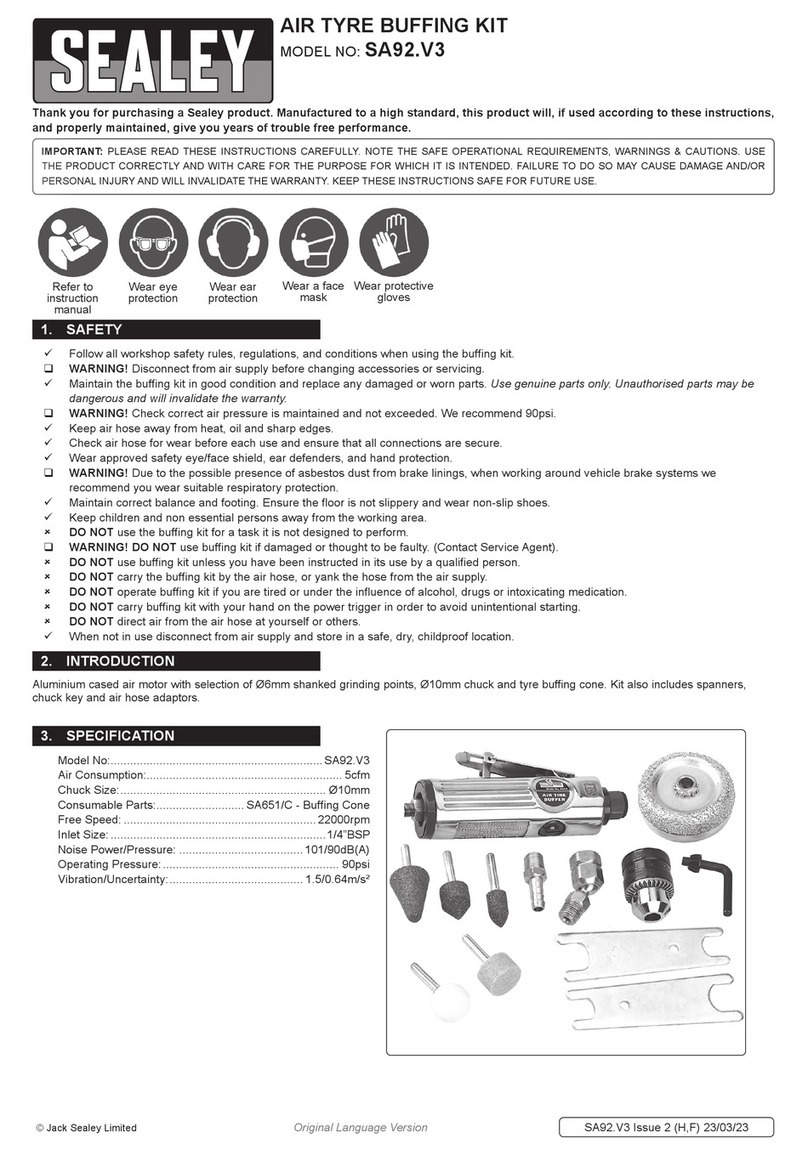

2. INTRODUCTION & SPECIFICATIONS

This design produces accurate automotive SAE

flares on 3/16” pipes. Lightweight body makes it ideal

for splicing in replacement sections of brake pipe

on-vehicle. Suitable for steel pipes. Supplied in

carry-case.

Original Language Version PFT12 Issue: 1 - 06/09/12

WARNING! Ensure you are familiar with the

various types of flare before using this

equipment.

WARNING! Before using the flaring kit,

ensure that you have read and understood

the ‘Safety Instructions’ in Section 1.

3.1 PREPARATION OF THE BRAKE PIPE

3.1.1 The end of the pipe must be cut square.

3.1.2 The outside edge of the pipe must be

chamfered to approximately 0.25mm x 45º.

3.1.3 Important!

If the pipe is plastic covered, this must be cut

back for 6mm from the end of the pipe to be

flared. Ensure the pipe is not scored or any

metal removed during this operation. DO NOT

use an abrasive cloth.

3.1.4 Important!

If the pipe is painted it is recommended that the

paint be removed for the length of the die by a

chemical paint remover, not an abrasive cloth.

Observe all manufacturers’ precautions when

using chemical paint remover. Finally remove

any grease present. These two operations will

improve the die jaw grip whilst flaring.

g.1

© Jack Sealey Limited