HYDRAULIC RAM 10TONNE

MODEL NO: PS990.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations are strictly adhered to when using tools.

DO NOT use ram or associated tools if damaged or worn.

9Maintain the ram and associated tools in good and clean condition for best and safest performance.

9 Checkthespecicationofthepullertoolyouwillbeusingtoensurethatitisratedtomatchtheforcethattheramcanapply.

9Ensure all threads are clean and well lubricated.

9Always check that the ram is correctly assembled into the puller being used and is square with the workpiece.

9If working on a raised vehicle, ensure that it is adequately supported with axle stands, ramps, etc. as appropriate.

9Wear suitable clothing to avoid snagging. DO NOT wear jewellery. Tie back long hair.

9Wear approved eye protection. A full range of personal safety equipment is available from your Sealey stockist.

9Where possible shield workpiece with canvas or similar to provide protection against failed parts.

8DO NOT use any tool or lever to turn the ram tommy bar, use hand eort only.

8DO NOT hit workpiece, or ram, with a hammer if workpiece has not moved with maximum puller force applied. Use a larger capacity puller.

9Account for all tools and parts being used and do not leave them in or on the vehicle.

2. INTRODUCTION

HydraulicrampistontsallSealeyhydraulicpullersetsandisalsosuitableforusewithotherpopularmakesofhydraulicgearpullers.Screw

mechanism converts power to 10tonne ram head with enough force to remove most stubborn bearings, pulleys and shafts.

3. SPECIFICATION

Model no: ............................................................... PS990.V2

Compatible with: ...............PS980, PS982, PS985, VSE127H

4. OPERATION

WARNING! Ensure that you read, understand and apply the

safety instructions in Section 1.

IMPORTANT: Always refer to the vehicle manufacturer’s service

instructions, or proprietary manual, to establish the correct

procedure and data. These instructions for use are provided as a

guide only.

4.1. Checkthatthespecicationofthepullertoolyouwillbeusingis

compatible with the ram unit.

4.2. Conrmthattheworkpieceisretainedbyinterferencet(parallelor

taper) only.

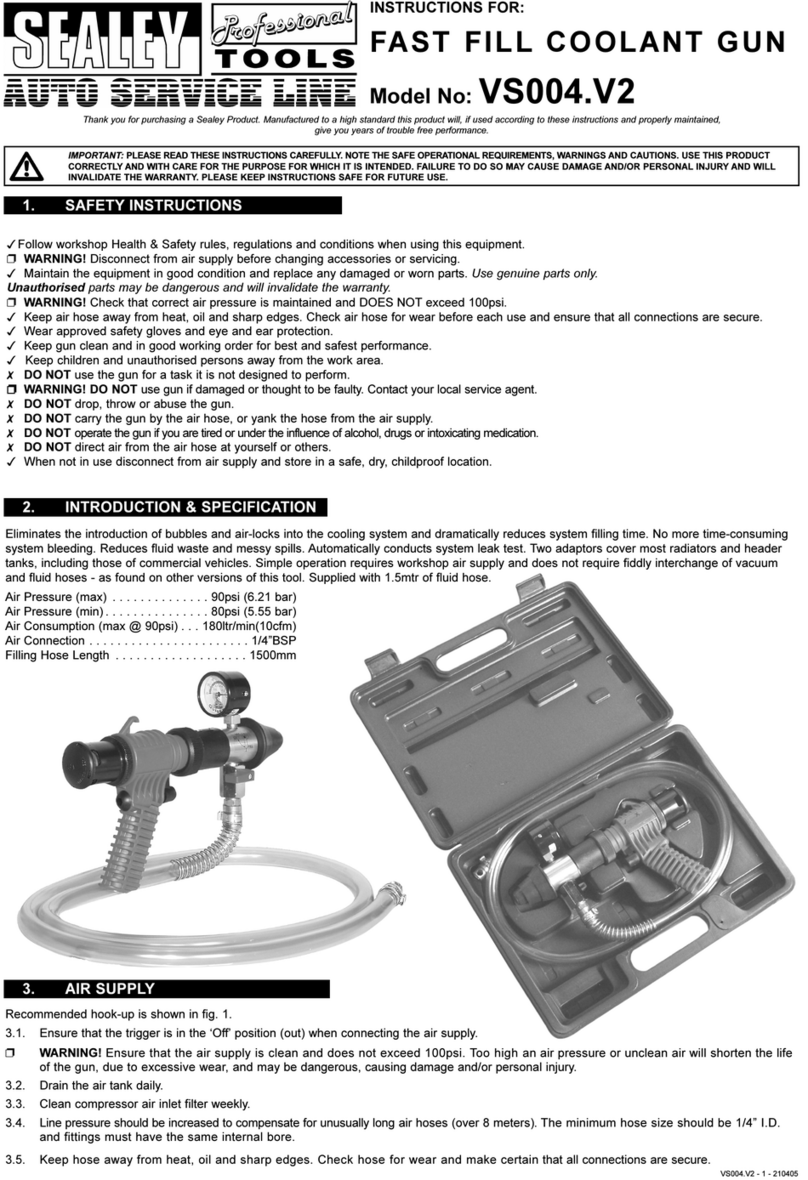

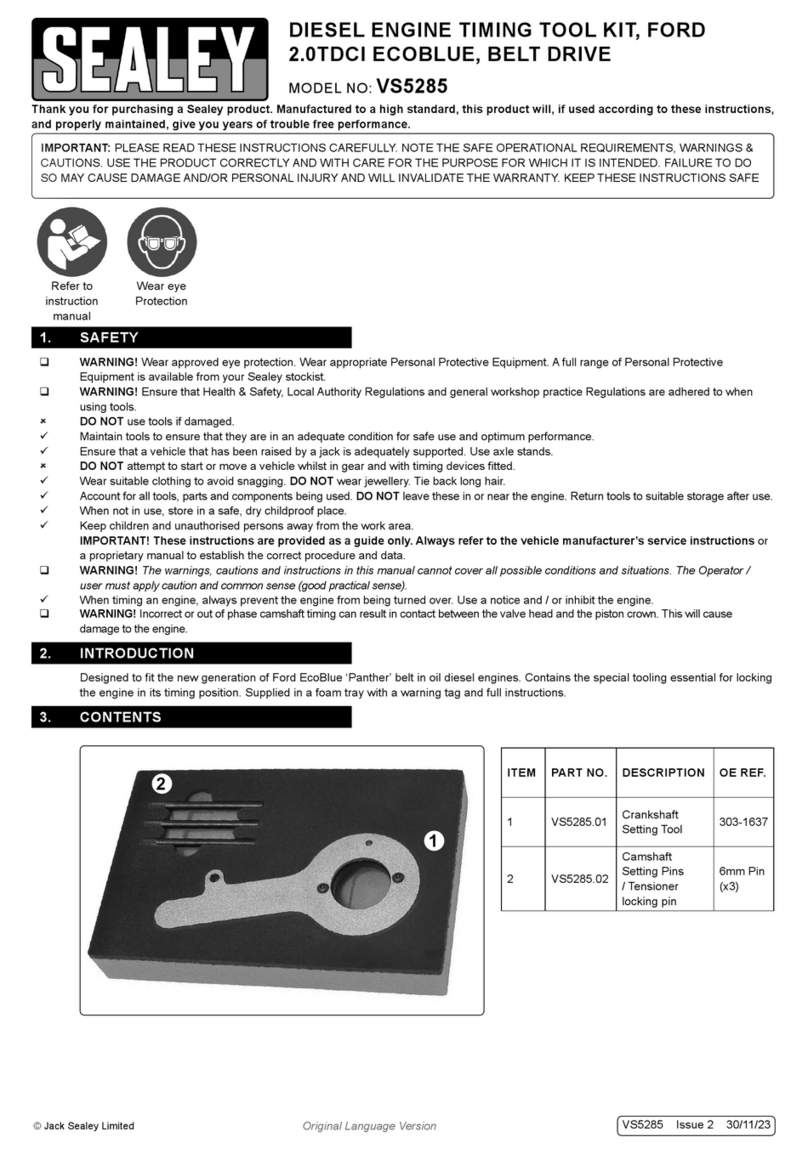

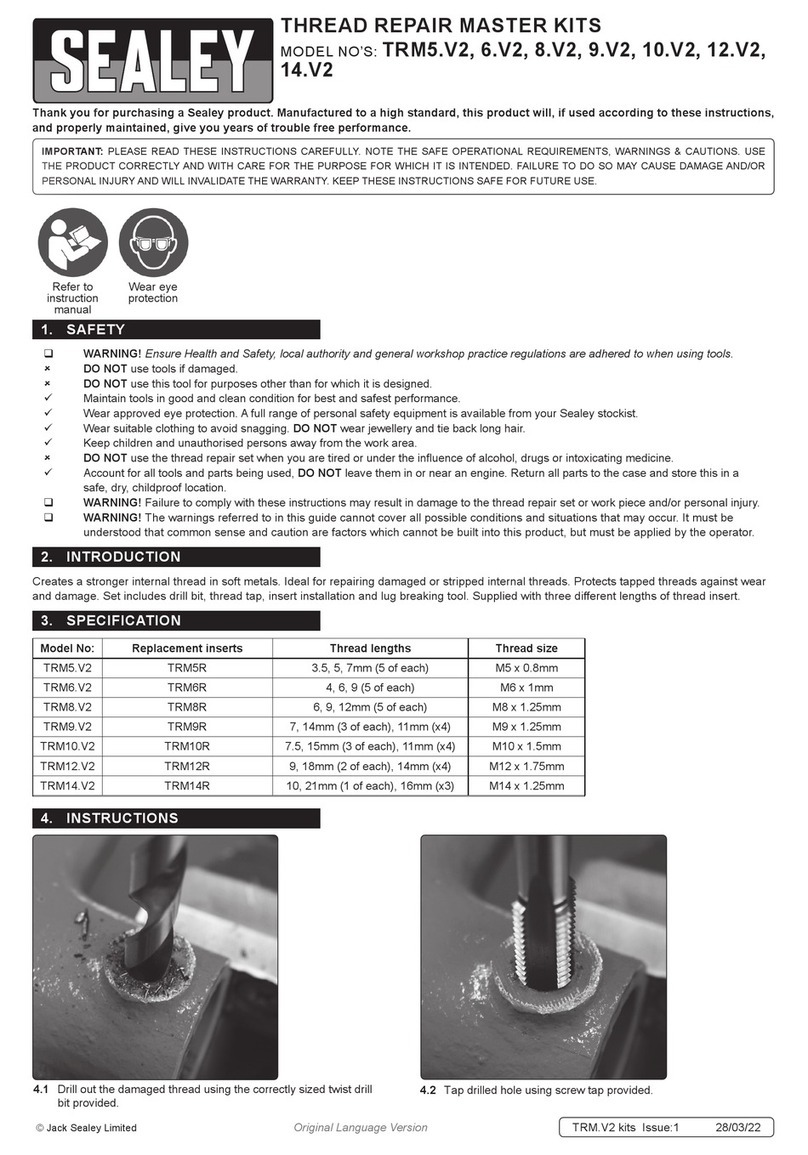

4.3. Assembletheramintothechosenpuller,(seetypicalpullersas

showning.1),andadjustT-handle(Fig.2.A)sothatTommy

bar(fig.2.B)isapproximately80mm(3”)abovetopofram,seefig.2.

4.4. Fitthepullertoanappropriatepositionbehindworkpieceandthen

screw the ram body down until it makes contact with the end of the

shaftfromwhichtheworkpieceistobepulled.(Iftheshafthasa

centre position machined into its end surface use a matching centre

adaptor to locate centrally with the shaft.

4.5. Turn T-handle clockwise, by hand only, to pull workpiece from shaft.

8DO NOT screwT-handleinfurtherthan25mm(1”)from

endoftheram(seeg.2).Ifworkpiecerequiresadditional

movement then unscrew T-handle to 80mm from end of ram, screw ram body down

so that centre adaptor again contacts shaft and then continue to draw workpiece up shaft.

IMPORTANT: Themaximumsafeloadforthepullercanbeachievedbyhandeortalone. The use

of tools or levers on the tommy bar to increase the load will damage the puller and may result

in injury. Such misuse will also invalidate the warranty.

If the workpiece does not move, with maximum puller force applied, DO NOT hit it, or the puller, in an

attempt to jar it free. Damage to puller/workpiece and personal injury may result. Use a larger capacity puller.

Refer to

instruction

manual

Wear eye

protection

Original Language Version

© Jack Sealey Limited

g.1

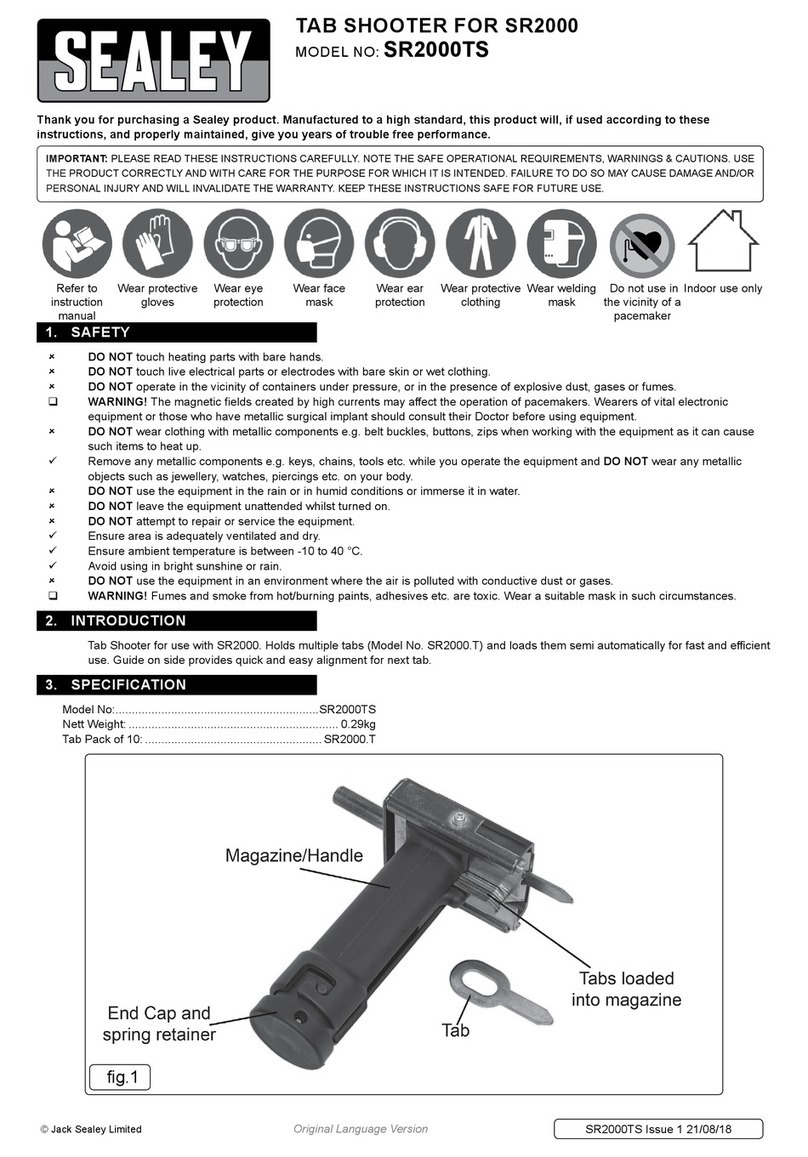

g.2

PS990.V2|Issue:2(H,F)18/02/20