INSTRUCTIONS FOR:

SNAP BODY REPAIR KITS

Models: RE97/4 & RE97/10C

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

2. CONTENT

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

p

p

WARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

3Familiarise yourself with the application and limitations, as well as the specific potential hazards, of the repair kit.

p

p

WARNING! No part of this unit or any accessory relating to the repair kit is designed for lifting loads. It is intended only as a

pushing device and must be used as such, with care.

p

p

WARNING! Disconnect the repair kit from the hydraulic pump before servicing or performing any maintenance on the unit.

3Maintain repair kit in good order. Replace/repair with genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

3Use qualified person to lubricate and maintain the hydraulic pump. DO NOT use brake fluid to top up hydraulic unit. Use Sealey hydraulic oil only.

3Keep the repair kit clean for best and safest performance.

p

p

WARNING! Ensure you know how much load you are pushing. Never exceed the maximum pushing capacity.

3Use only with the supplied Sealey hydraulic pump and accessories. Other equipment may damage unit and will invalidate your warranty.

3The kit accessories may be used with other popular makes of kit.

3Ensure there is positive engagement of repair kit accessories with the vehicle body before pushing.

3Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

3If working on an off centre load, pump with care. If you feel undue resistance, stop and re-adjust the set-up.

p

p

WARNING! Keep your hands, body and clothing away from the repair kit and accessories when in use. Take any necessary

precautions to protect your personal safety and that of others whilst using the repair kit.

3Ensure the hydraulic hose is not bent or kinked.

3Keep non-essential persons away from the operating area. Be aware of the locations of other persons assisting you.

3When releasing tension from the load be sure to undo the hydraulic valve VERY slowly.

7DO NOT operate the repair kit if any parts are damaged or missing as this may cause failure and/or personal injury.

p

p

WARNING! DO NOT use repair kit as a lifting device of any type. DO NOT use for any purpose other than for which it is designed.

7DO NOT over extend the ram as the plunger may be forced out of the cylinder.

7DO NOT heat accessories as this may weaken them.

7DO NOT modify accessories for use with this kit.

3When not in use, place dust cap on end of hydraulic hose and store the kit, in the case, in a safe, dry, childproof location.

Only fully trained and qualified persons should use this equipment. These instructions are not a substitute for user receiving full

supervised training by a qualified person. It is important the user understands the applications, limitations and potential hazards of the product.

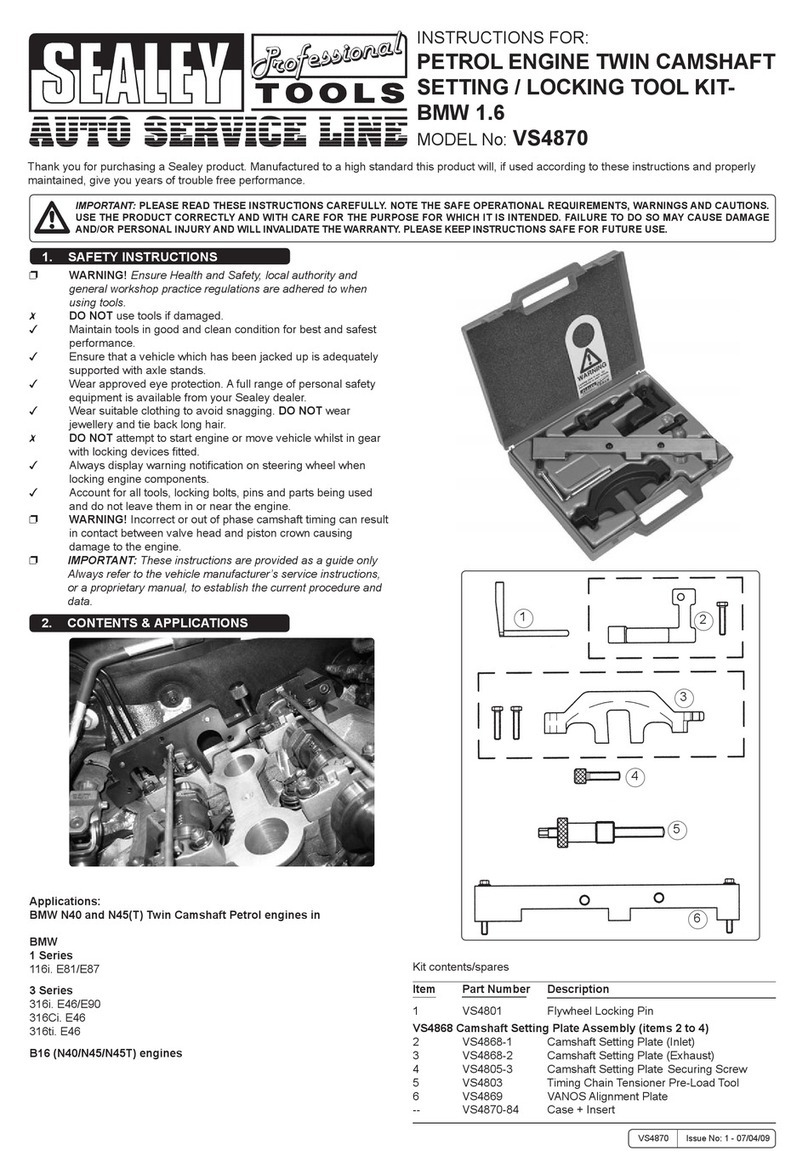

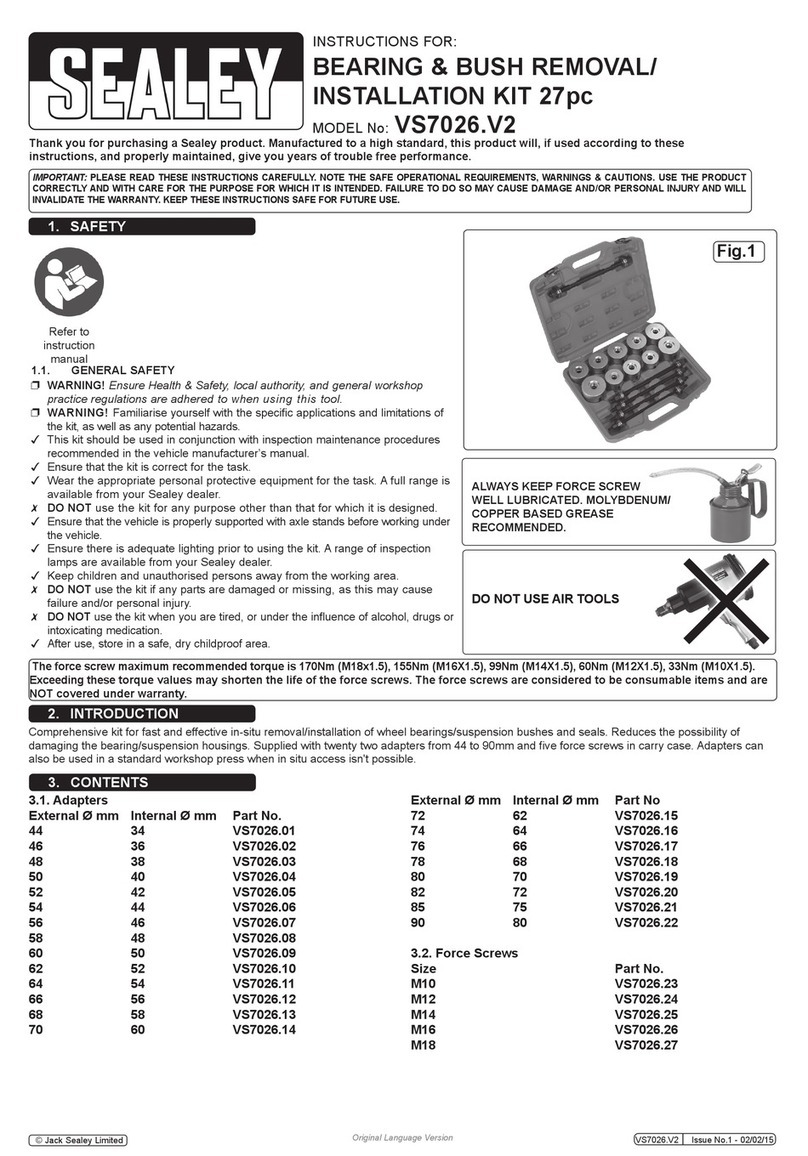

ITEM PART NO. DESCRIPTION

1RE97.4-01 Pump assembly

2 RE97.4-02 Ram assembly

3RE97.4-03 Hose assembly

4 RE97.4-A14 Extension Tube, 19 1/2

5 RE97.4-A01 Extension Tube, 16 1/2

6RE97.4-A02 Extension Tube, 8 1/2

7 RE97.4-A03 Extension Tube, 5

8 RE97.4-A04 Extension Tube, 3 1/4

9RE97.4-A05 Male connector

10 RE97.4-A06 Serrated sadle

11 RE97.4-A07 Wedge head

12 RE97.4-A08 Flat base

13 RE97.4-A09 90º Combination head

14 RE97.4-A10 Rubber head

15 RE97.4-A11Ram toe

16 RE97.4-A12 Plunger toe

17 RE97.4-A13 Hydraulic spreader

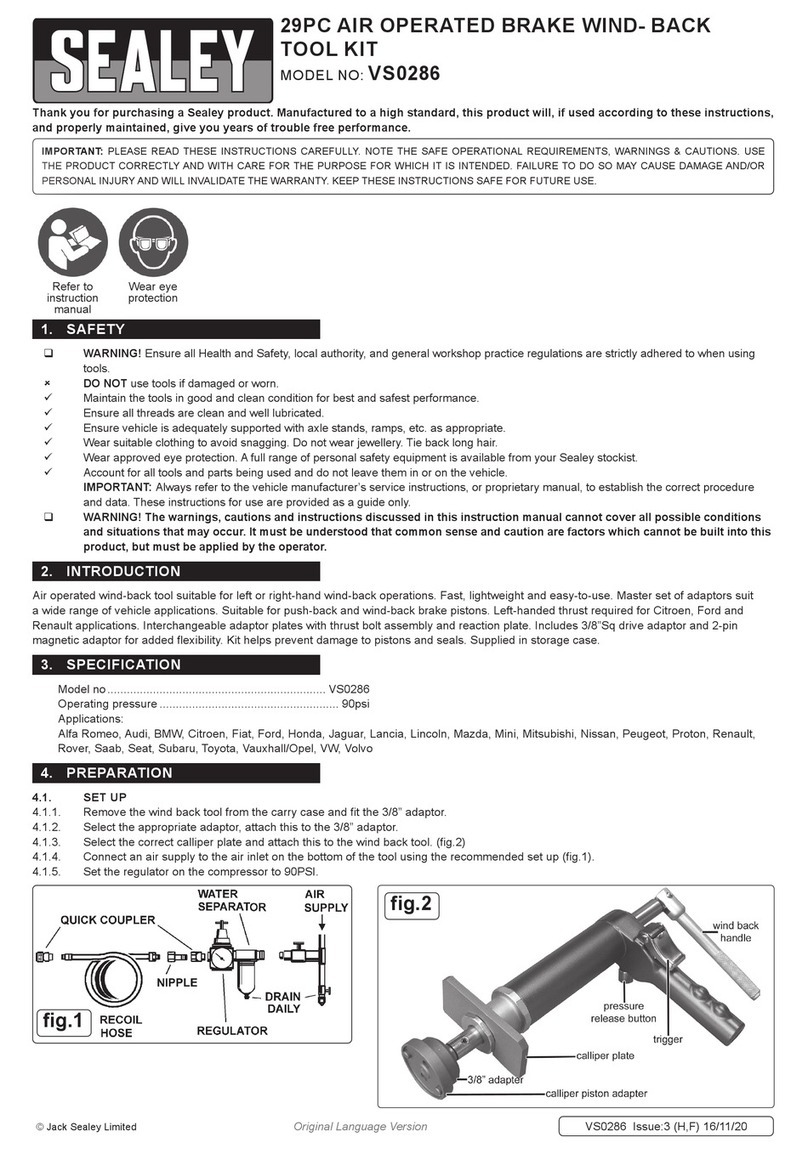

ITEM PART NO. DESCRIPTION

1 RE97.10C-40 Pump assembly

2RE97.10C-41 Ram assembly

3RE97.10C-42 Hose assembly

4 RE97.10C-A02 Extension Tube, 27

5RE97.10C-A03 Extension Tube, 18

6RE97.10C-A04 Extension Tube, 10

7 RE97.10C-A05 Extension Tube, 5

8RE97.10C-18 Male connector

9RE97.10C-07 Serrated sadle

10 RE97.10C-16 Wedge head

11 RE97.10C-13 Flat base

12 RE97.10C-17 90º Combination head

13 RE97.10C-12 Rubber head

14 RE97.10C-14 Ram toe

15 RE97.10C-15 Plunger toe

16 RE97.10C-11 Hydraulic spreader

17 RE97.10C-01 Metal Box

RE97/4, RE97/10C - 1 - 060802

RE97/4

RE97/10C