AK452X.V2 & AK453X.V2 - 1076 - (2) - 171201

!WARNING! Disconnect the pump from the air line before attempting any service or maintenance.

7.1. Air line lubricator (fig.2 item O). This unit is designed to automatically lubricate the pump through the air intake.

The unit must be kept topped up with good quality air oil (our reference: ATO/500 500ml size or ATO/1000 1ltr size).

To adjust the oil flow turn the oil regulator screw on the top of the unit. Turn screw anticlockwise to increase the flow

and clockwise to decrease flow. The oil supply required to lubricate the pump is minimal. For an initial setting turn

adjusting screw on the top of the unit fully home and then open by 1/4 of a turn. To change and clean the oil unit

unscrew the bowl and retain the sealing ring. Empty, clean and re-fill to maximum line and replace ensuring the sealing ring is

fitted correctly. Do not over tighten the bowl. Contact your Sealey dealer for parts and information.

7.2. Cleaning. Clean pump and air units with clean damp cloth. Mild detergents may be used to remove grease.

DO NOT use solvents or abrasives and do not get the pump or air units wet.

!WARNING! When exchanging a polycarbonate bowl ensure the suction tube is protected to avoid dirt particles being transmitted to a new bowel. Always

clean new delivery lines ensuring all metal shavings have been removed before connecting the pump and control valves. Failing to do so may damage

the unit and will invalidate your warranty.

6.1 Turn the air pressure on and check to ensure there are no leaks in the system.

6.2 Adjust the air pressure using the knob on the top of the air regulator (fig 2. item R). Unlock the knob by pulling it

upwards and then turning it until the gauge indicates the recommended operating pressure of 6.0bar/87psi. Push the

knob down again to lock it. It is important to maintain the correct operating pressure to ensure that the control valves

and connectors are not damaged, and to prevent leakage in the delivery lines.

6.3 Prime unit by operating grease control valve (fig 2. item Y) until lubricant emerges from end of the gun. The unit is

now ready for use.

6.4 When not in use, turn the air supply off and disconnect the unit from the air supply. Store the grease unit in a safe, clean,

dry, childproof area.

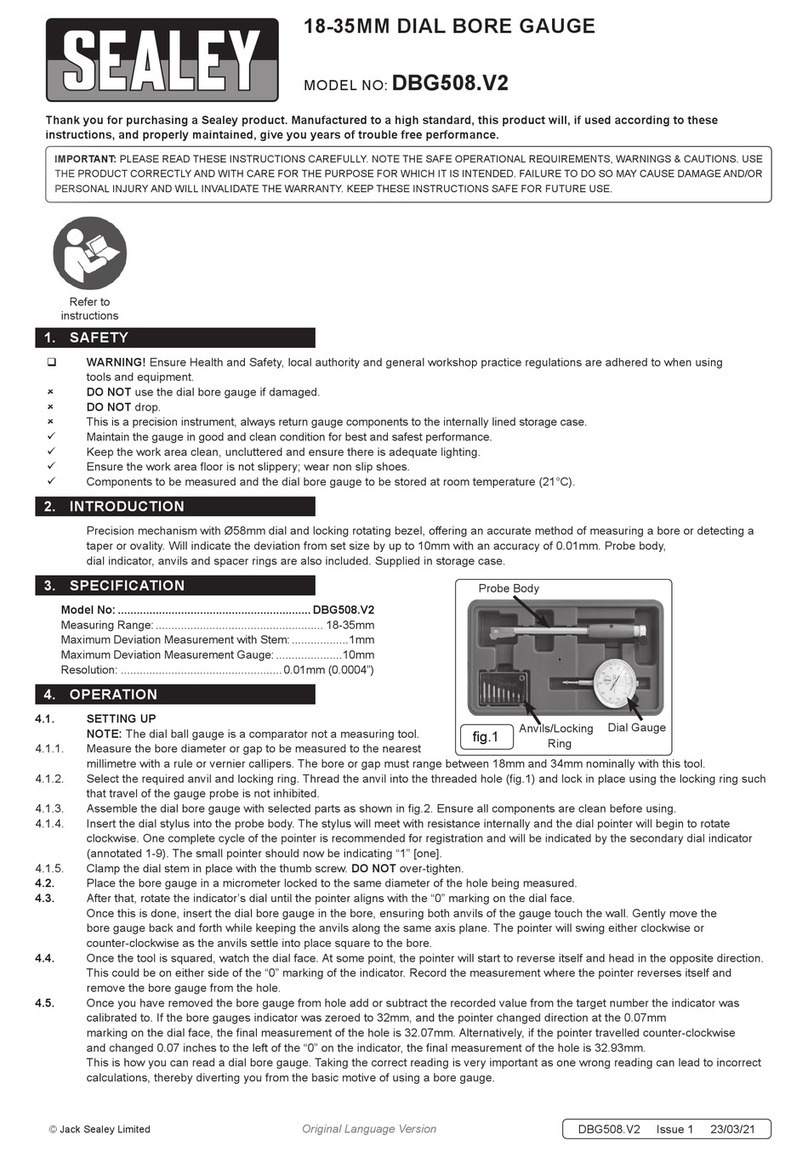

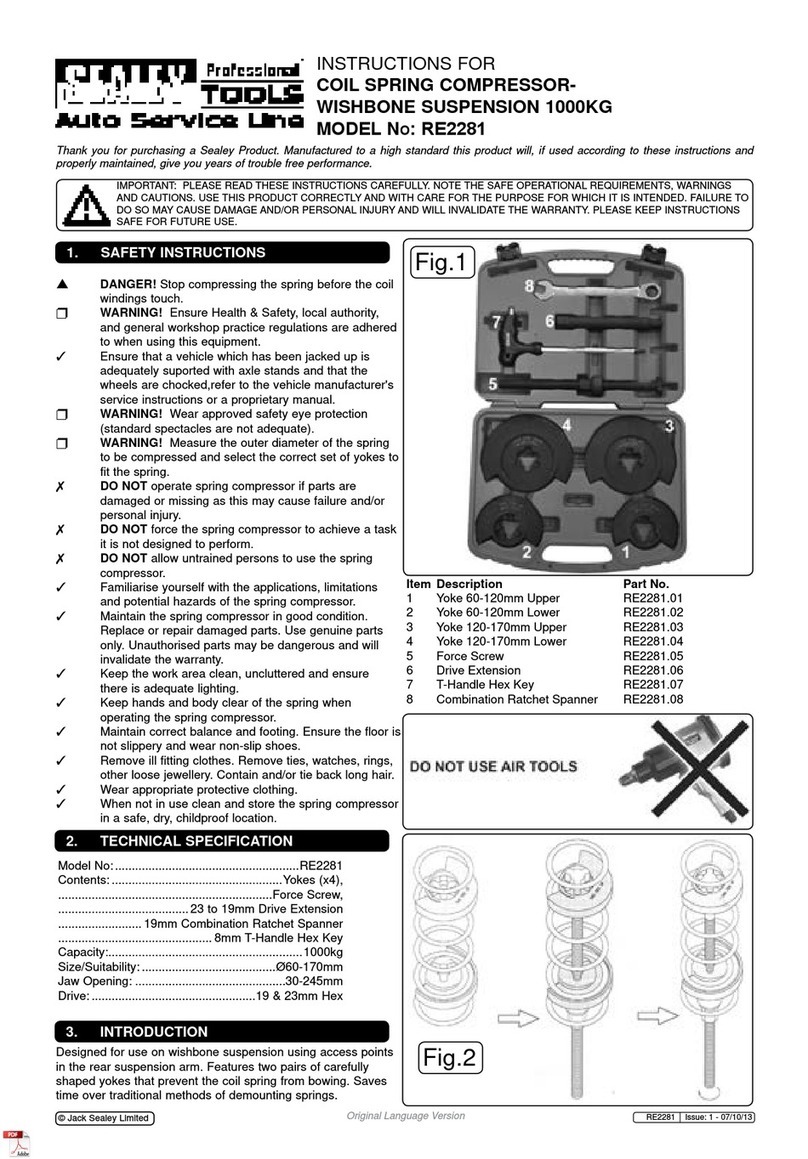

5.0 Installation. ( Refer to fig.2 )

!WARNING! Clean new delivery lines ensuring all metal shavings have been removed before

connecting the pump and control valves. Any dirt in the inlet hoses will damage the unit and

may invalidate your warranty.

5.1 Place the grease bucket (X) onto the platform of the trolley and push it back until it touches the two stops

provided. Secure the container to the trolley using the straps provided. (see fig.1)

5.2 Remove the original lid supplied with the grease bucket and store it for future use.

5.3 Introduce the follower plate (A) into the top of the grease bucket (X) and settle it down onto the surface of

the grease.

5.4 Take the three legged shaft guide (B) and loosen all six butterfly nuts. Adjust the length of the

legs to suit the size of the grease bucket. Place the shaft guide onto the rim of the grease bucket

and align the central hole with the hole in the follower plate below. When aligned tighten all the butterfly nuts

ensuring that those at the end of the legs have caught under the rim of the bucket.

5.5 Slide the circular lid (C) onto the shaft of the pump as far as it will go.

5.6 Lift the pump and lid over the grease bucket and allow the shaft to pass through the shaft guide and follower plate

and sink down to the bottom of the bucket. Let the lid slide down the shaft to cover the top of the bucket.

5.7 Connect the in-line air regulator (R) and air oiler (O) together using the long bolts and nuts provided. (The nuts

slide into the recesses in the front and back of the regulator body.) Ensure that the air flow arrows moulded into the top

of each unit body are pointing in the same direction and that both arrows are pointing towards the pump air inlet. The air

oiler should be situated between the air regulator and the pump as indicated in fig.2.

5.8 Screw the circular pressure gauge (L) into whichever side of the air regulator is most convenient for reading. Seal

the unused mounting position using the blanking plug provided.

5.9. Connect the regulator assembly to the pump air inlet using the 1/4” bsp fitting provided (H).

5.10 Connect the ‘Z’ swivel assembly (Z) to the grease gun (Y) and connect the grease hose (E) to the ‘Z’ swivel.

Connect the other end of the grease hose to the grease outlet on the pump (G).

Note: We recommend that PTFE sealing tape is used on all connections.

5. ASSEMBLY & INSTALLATION fig 2.

THE PROBLEM THE CAUSE THE SOLUTION

1. Air motor runs slowly or

not at all

2. Air motor is running but

pump is too slow or not

working at all.

3. Air motor is running but

no pressure is generated.

4. Air escapes from the

muffler when the pump is

not operating

1.1. Air pressure is too low.

1.2. Muffler or filter is blocked or dirty.

2.1. Grease filter is blocked.

2.2. Grease is too stiff.

2.3. Air pockets in grease container.

2.4. Grease container dented.

3.1. ‘O’rings,washers or valves within pump

are damaged or dirty

4.1. The plunger is damaged.

4.2 The ‘O’ rings or the distributor seal are

damaged.

1.1. Adjust air pressure to a minimum of 3bar.

1.2. Remove muffler (part No.20) and/or filter (part No.11), clean and replace.

2.1. Remove and clean filter. (part No. 41)

2.2. Remove drum to warmer area allow temp of grease to rise above 15OC

2.3. Viscosity too high. Temperature must be above 15OC. Then compact the

grease by pushing the follower plate down.

2.4. Push the follower plate down past the dented area of the container.

3.1. Clean or replace the relevant components. Servicing by an approved Sealey

dealer is recommended

4.1. Replace plunger. ( part No.5 ) Servicing by an approved Sealey

dealer is recommended.

4.2 Replace parts ( part No.19.6 ) using complete repair kit.

8. TROUBLE SHOOTING

6. OPERATING INSTRUCTIONS

7. MAINTENANCE

Declaration of Conformity We, the sole UK distributor, declare that the products listed below are in conformity with the following EEC standards and directives

The construction files for these products are held by the Manufacturer and may be inspected

by a national authority by contacting Jack Sealey Ltd

For Jack Sealey Ltd. Sole distributor in the UK of Sealey Power Products

Air Operated Grease Guns

Models AK452X.V2 & AK453X.V2

98/37/EC Machinery Directive 20th August 2001

Signed by Mark Sweetman